Construction process for installing elastic slippage shock isolation support

A seismic-isolating bearing and elastic sliding technology, which can be applied to building types, buildings, protected buildings/shelters, etc., can solve problems such as the difficulty of burying the anchors of the embedded slab and the difficulty in ensuring the density of the concrete under the slab. , to achieve obvious social and economic benefits, improve structural safety performance, and reduce engineering costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the present invention will be described in detail with reference to embodiments.

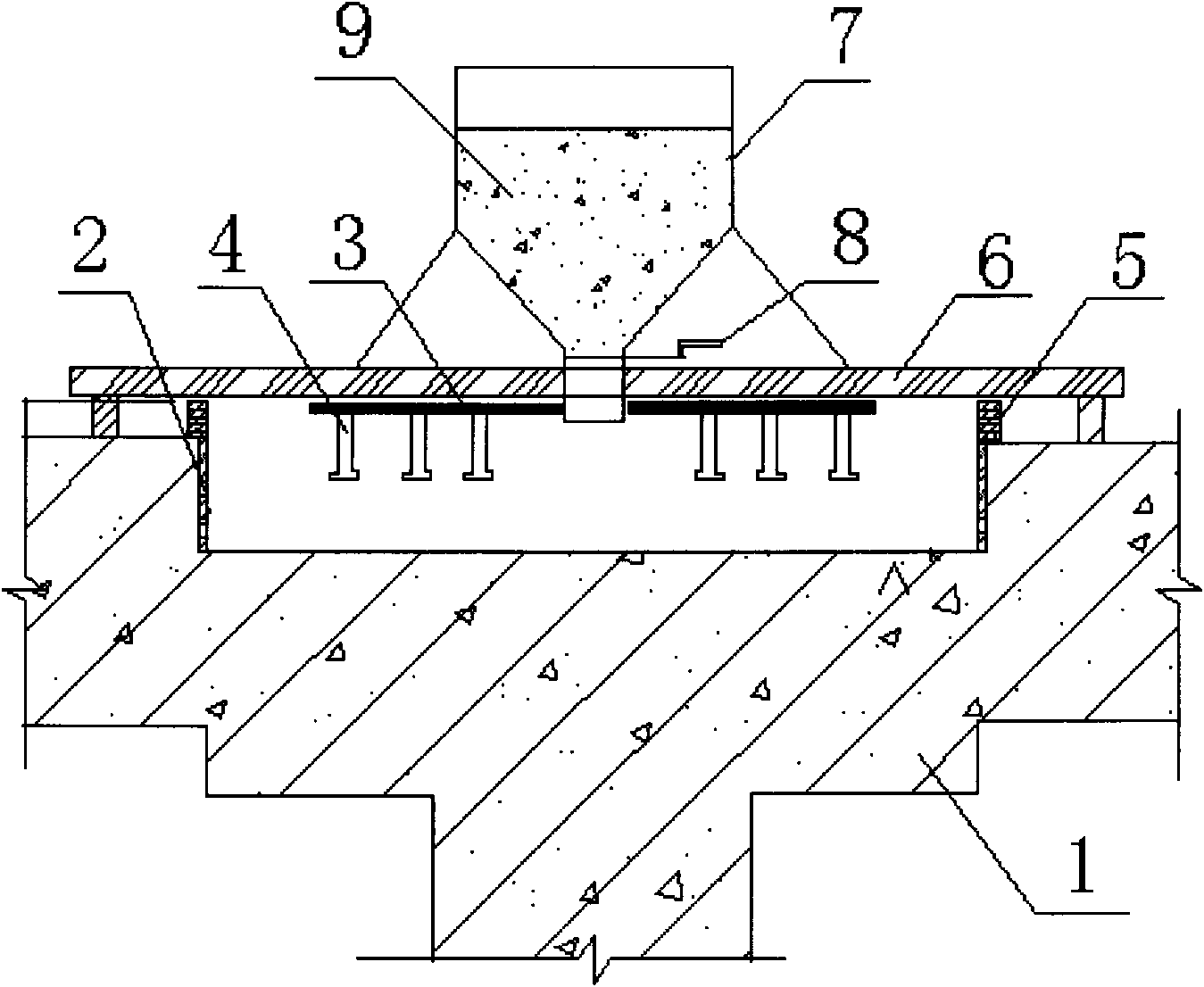

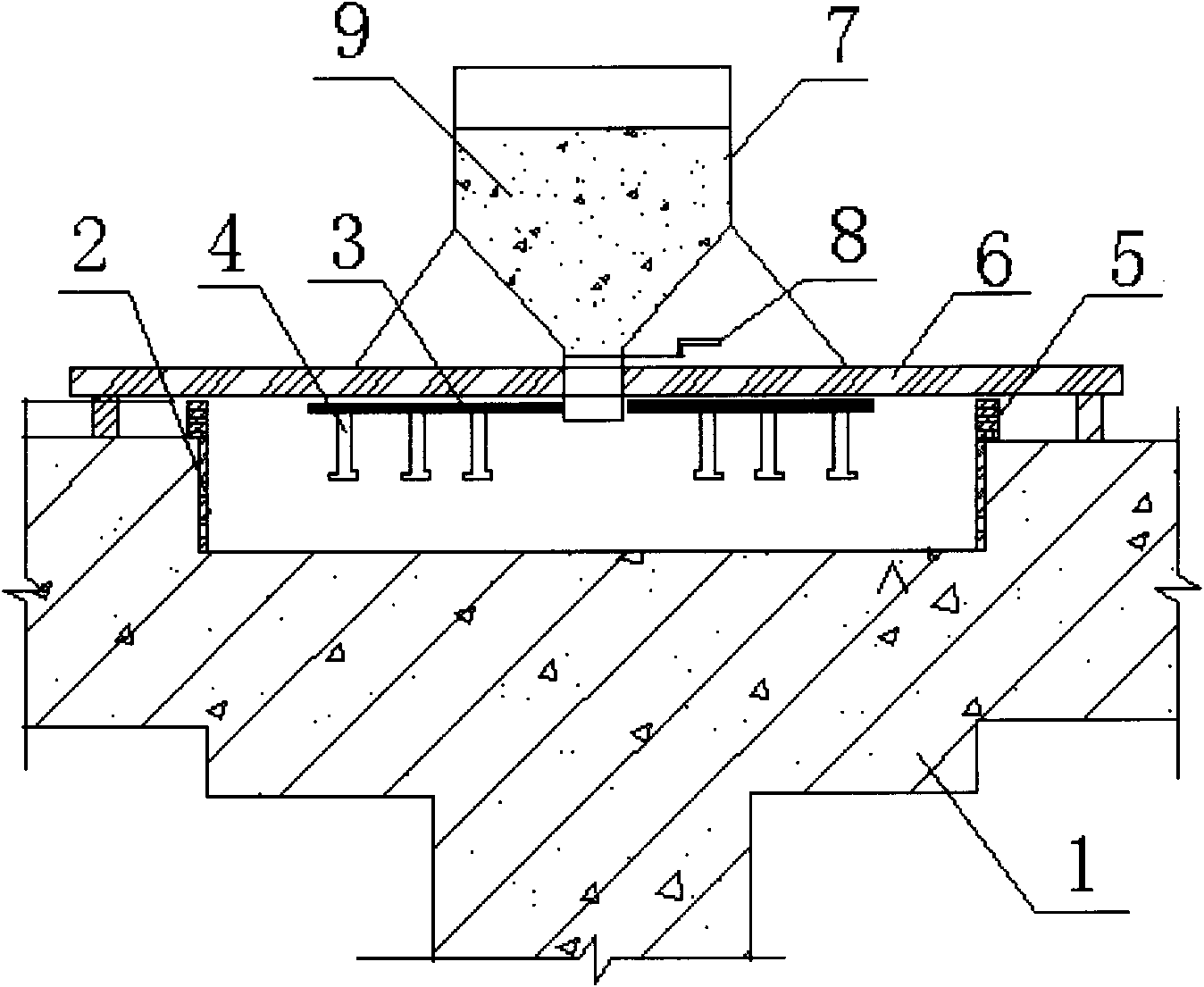

[0021] As shown in the figure: 1. Substructure; 2. Permanent formwork without chiseling; 3. Lower embedded plate; 4. Embedded plate connector; 5. Formwork; 6. Steel beam support; 7. Pouring hopper; 8. Feeding valve; 9. Shrinkage compensation concrete.

[0022] 1. Construction preparation

[0023] 1. The quality of the elastic sliding seismic isolation support and connecting accessories must meet the requirements of the design and related standards, and there is a factory quality certificate. The seismic isolation support should be fully accepted when entering the site.

[0024] 2. The spare parts of the elastic sliding shock isolation bearing are ready, the trial assembly is qualified, and the positioning mark is made.

[0025] 3. The anti-corrosion materials should meet the design requirements and have a factory quality certificate.

[0026] 4. The anchoring steel bar meets the design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com