A concrete shotcreting car and a jib system thereof

A shotcrete truck and concrete technology, which is applied to the boom system of the concrete shotcrete truck and the field of the concrete shotcrete truck, can solve the problems of potential safety hazards, increased costs, and impact on lighting effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The core of the present invention is to provide a boom system of a concrete spraying truck, the lighting device of the boom system can automatically adjust the angle with the change of the nozzle position, so that the construction position always has a good lighting effect, and is far away from the construction position. , longer service life. Another core of the present invention is to provide a concrete shotcrete vehicle comprising the above boom system.

[0023] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

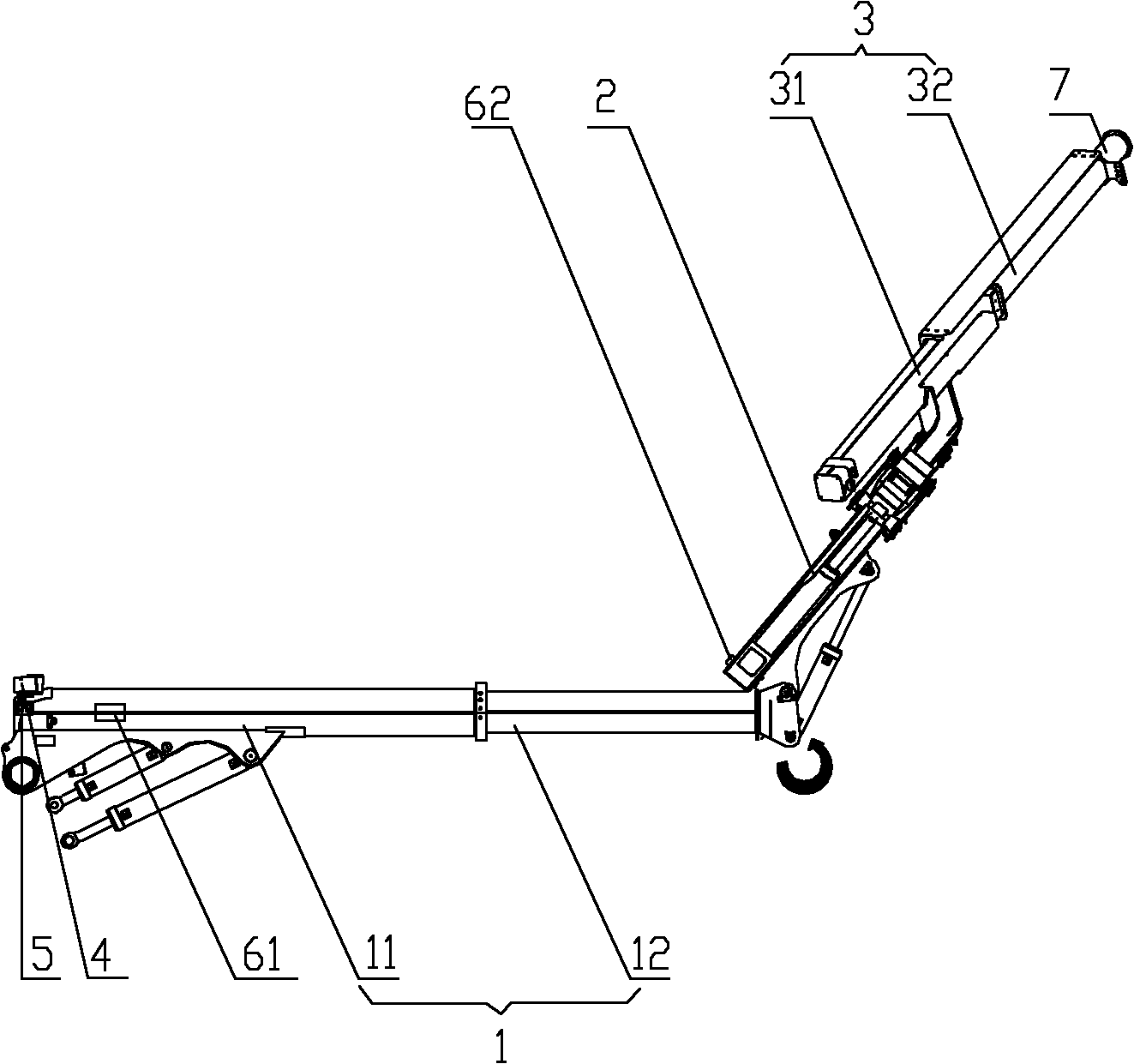

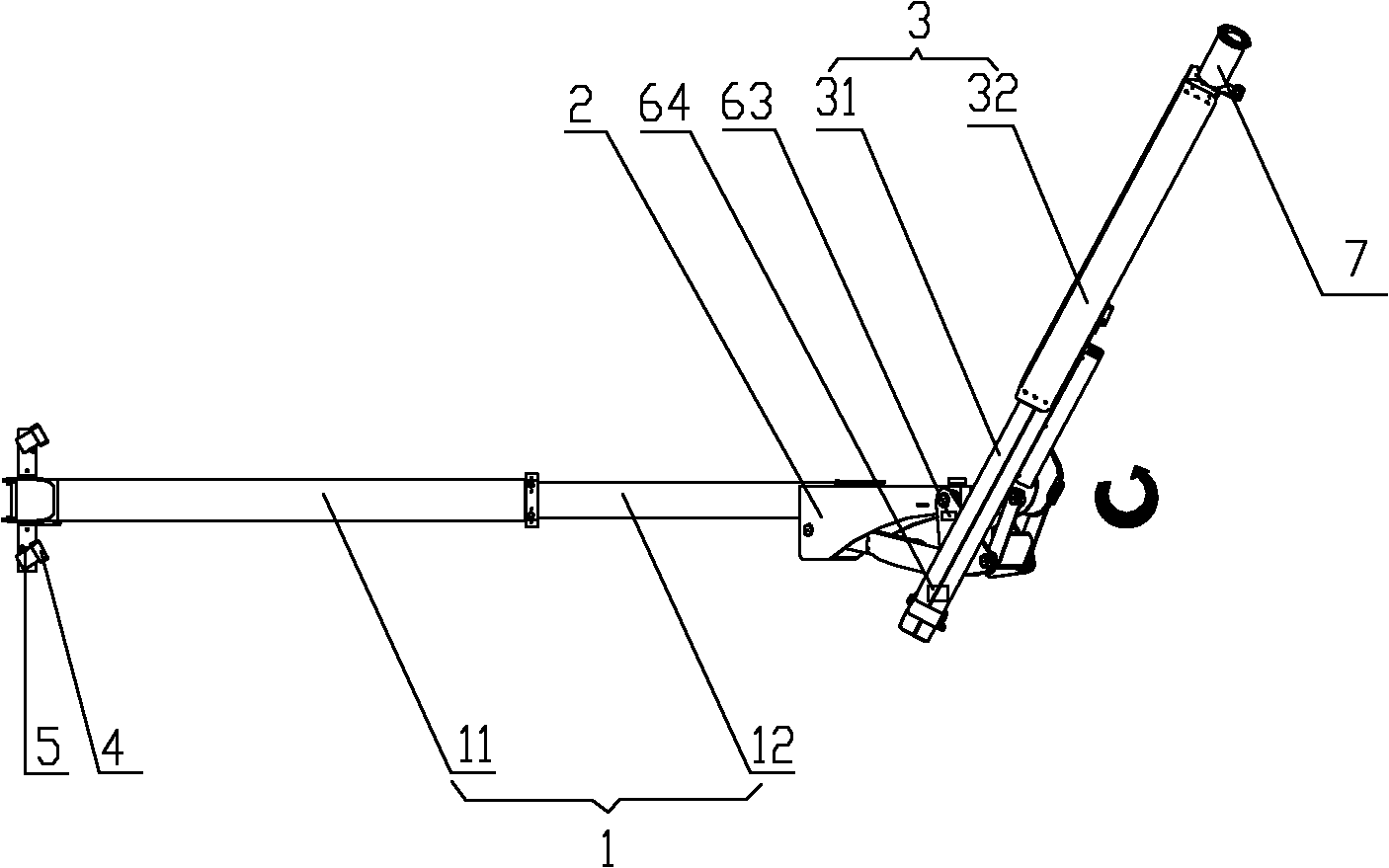

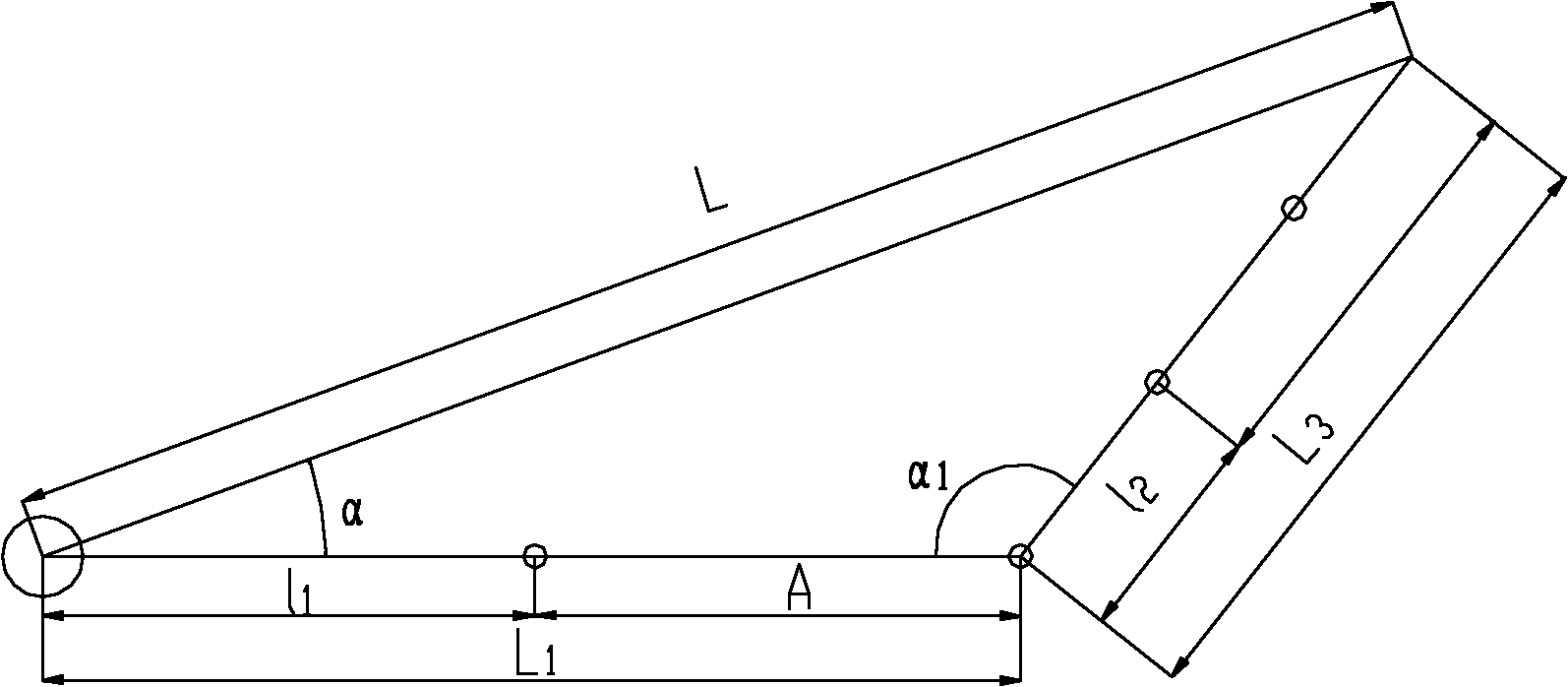

[0024] Please refer to figure 1 and figure 2 , figure 1 It is a front view of a specific embodiment of the boom system provided by the present invention; figure 2 for figure 1 Top view of the boom system shown.

[0025] The concrete shotcrete vehicle bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com