Reformed-gas-based device and method for purifying engine tail gas

An engine and reformed gas technology, applied in exhaust devices, engine components, combustion engines, etc., can solve the problem of high cost of precious metal catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

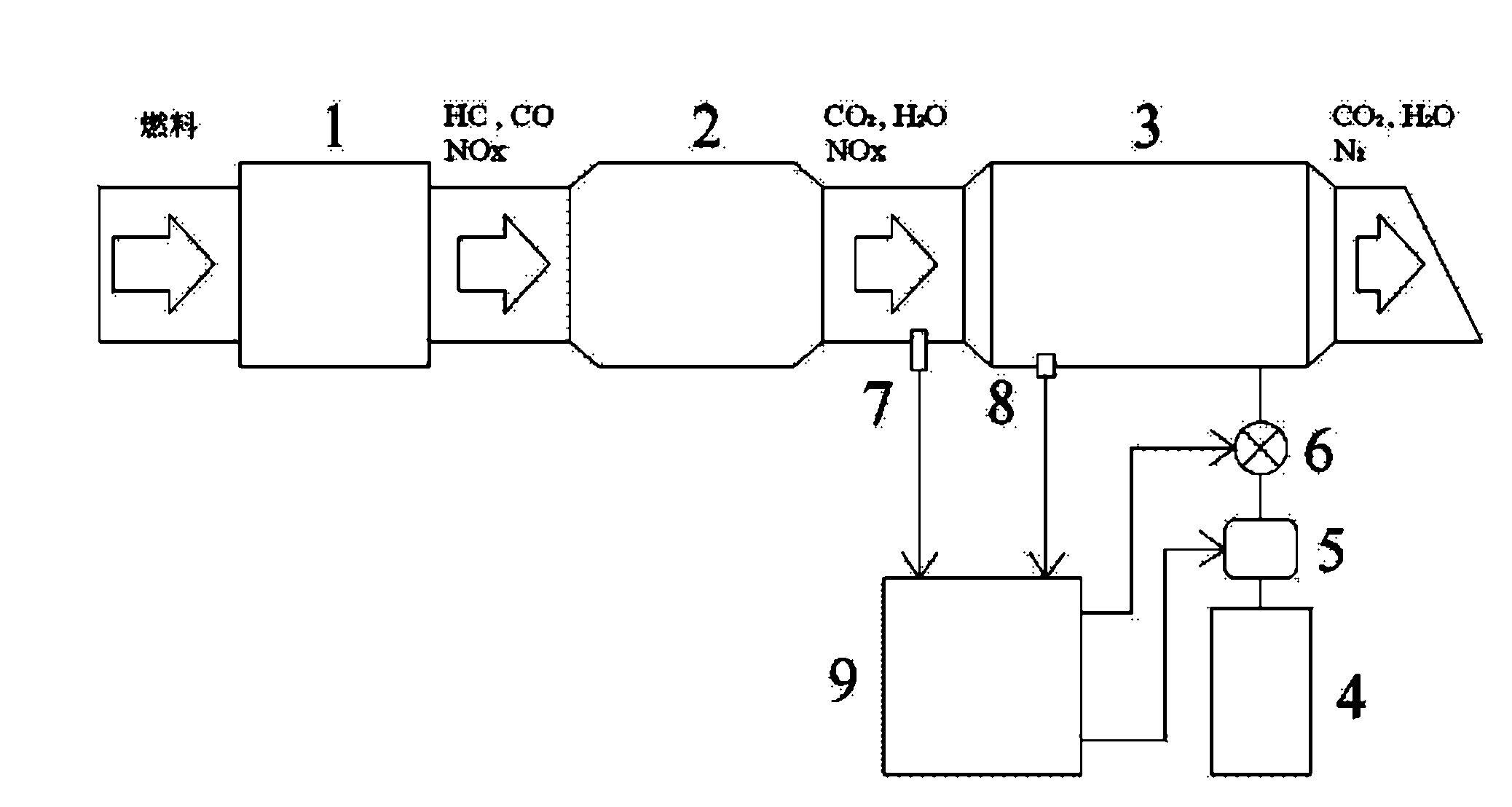

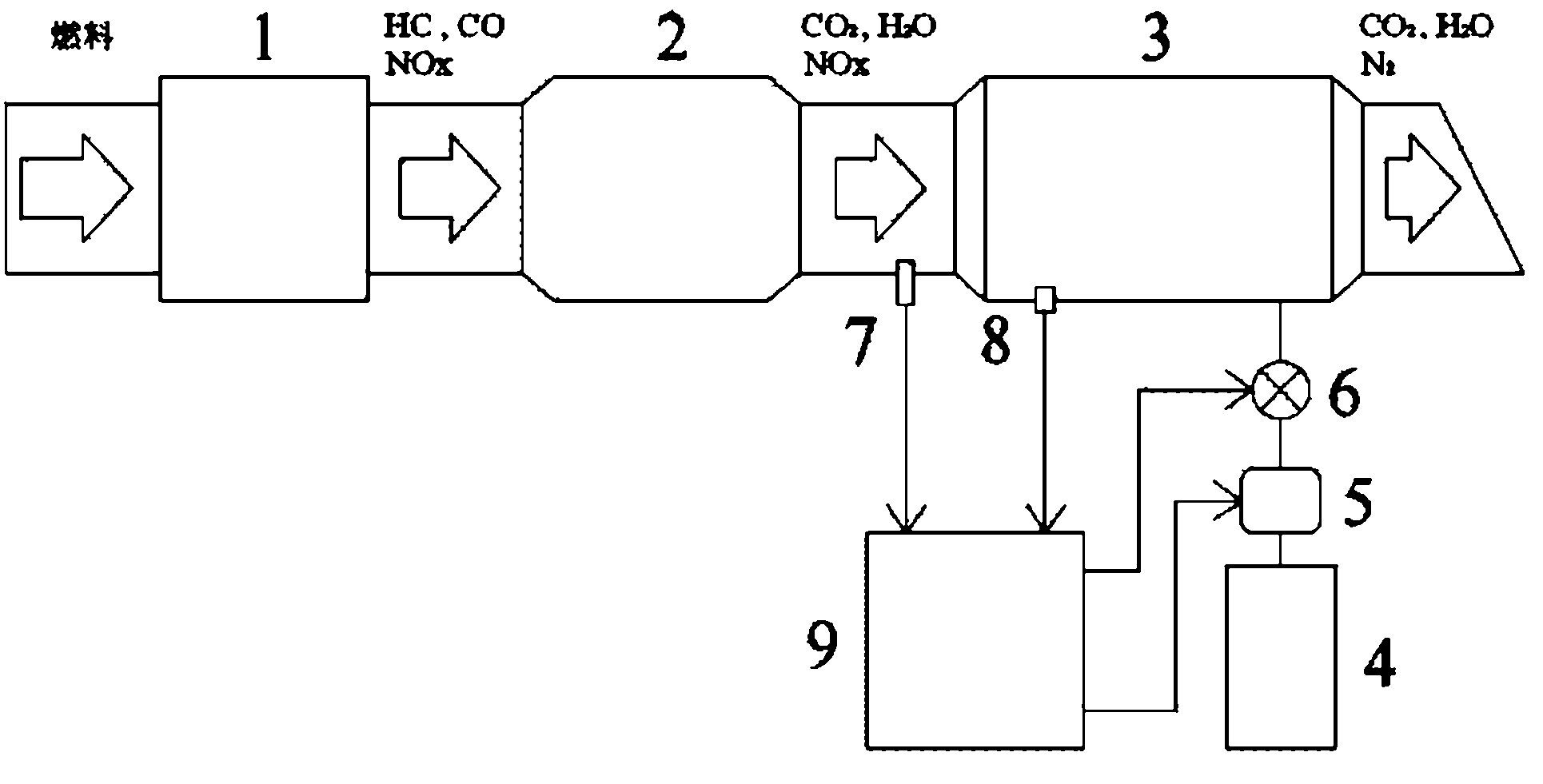

[0016] Combine below figure 1 This embodiment will be described. The system can be divided into three parts: a. Exhaust gas circulation unit; b. Reforming fuel supply unit; c. Electronic control unit.

[0017] a. Exhaust gas circulation unit: Engine 1, Pt-based catalytic reformer 2, and Cu-based catalytic reformer 3 are connected in sequence. The fuel enters the engine 1, and the combustion products first pass through the Pt-based catalytic reformer 2, and then pass through the Cu-based catalytic reformer. b. reforming fuel supply unit: the reforming fuel tank 4 is connected to the Cu-based catalytic reformer 3 through the reforming fuel pump 5, and the reforming fuel pump 5 is connected to the Cu-based catalytic reformer The reformer 3 is also connected with a reforming fuel flow control solenoid valve 6; the reforming fuel pump 5 pumps the fuel in the reforming fuel tank 4 into the Cu-based catalytic reformer 3, wherein the reforming fuel flow control solenoid valve 6 contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com