Semi-pantograph disconnector

A technology of disconnector and boom, applied in the field of semi-boom type disconnector, which can solve the problems of being covered by ice and damaging the effective electrical contact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Note that anything found to be known during the patent process is understood to be the subject of no claim and disclaimer.

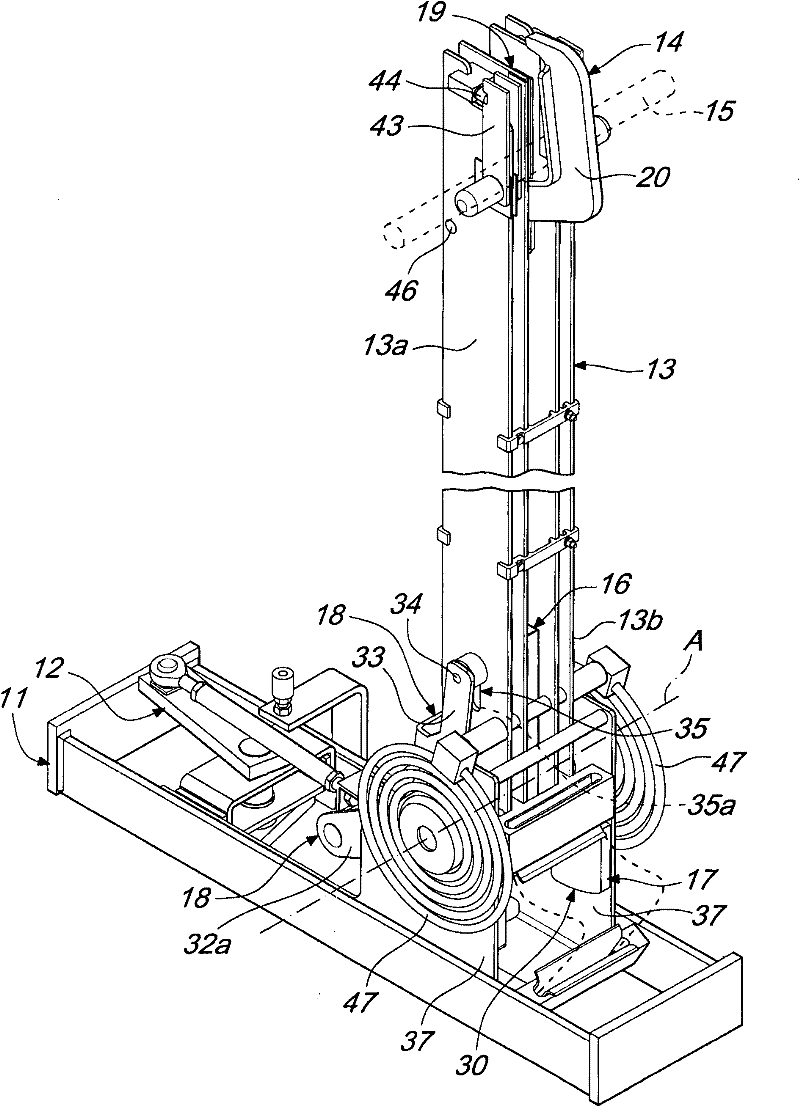

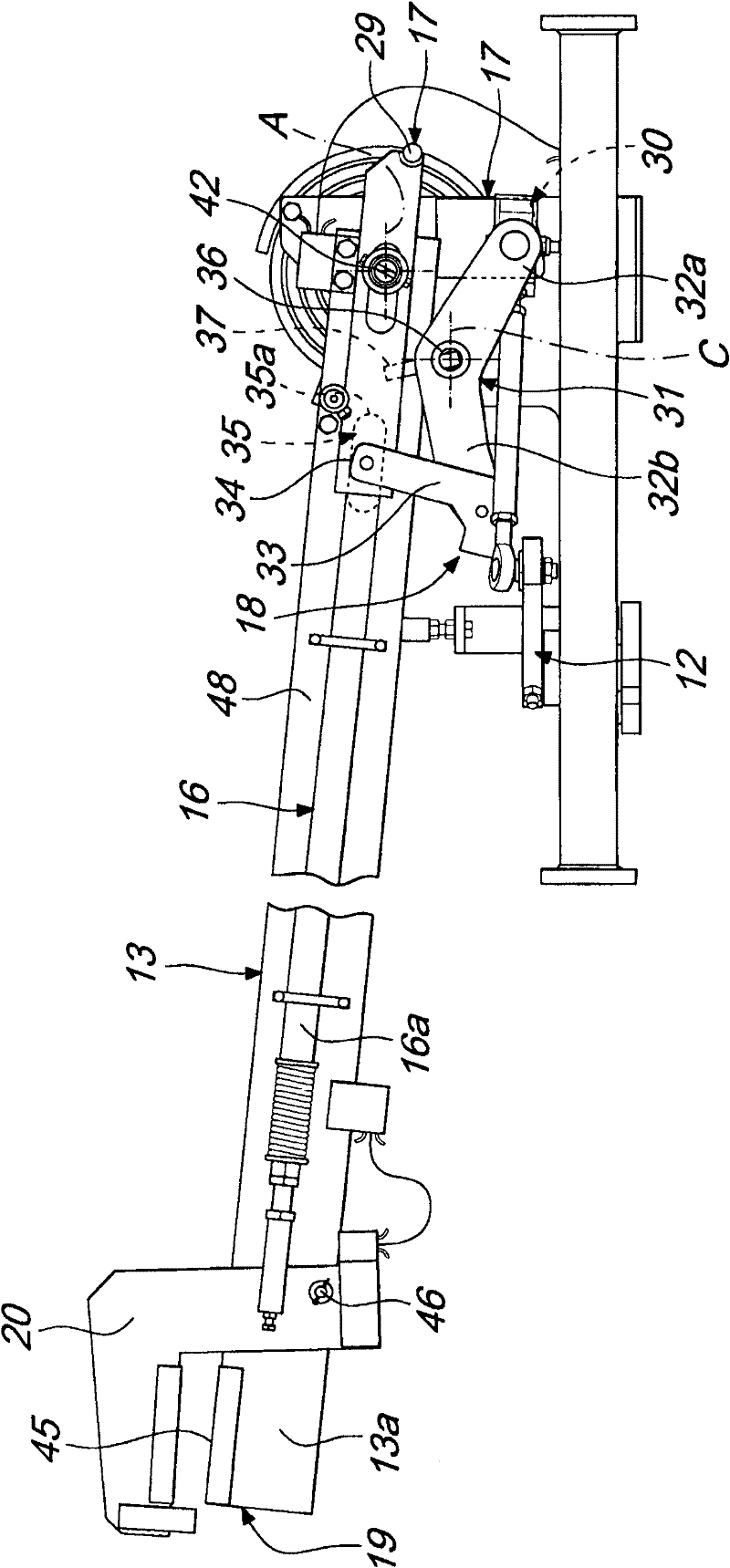

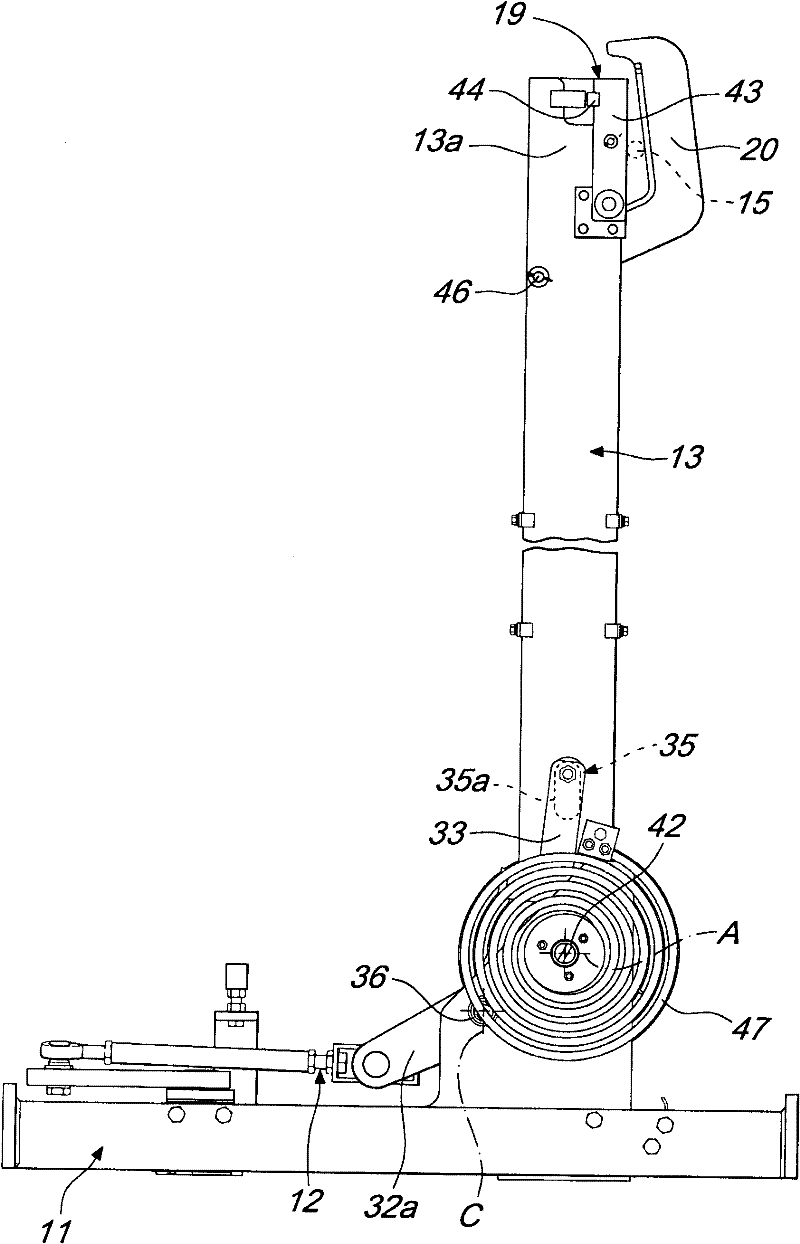

[0030] Referring to the drawings, reference numeral 10 generally designates a semi-boom breaker, which includes:

[0031] base 11, which supports the motor movement system 12,

[0032] An arm 13 , which at a first end 13 a has a bearing plate 14 for clamping a boom 15 , is hinged at a second end 13 b to a base 11 so that it can swing about an axis A of rotation.

[0033] In this way, by rotation about the axis of rotation A by actuation of the motor-kinematic system 12, the arm 13 can be reversibly transferred from the off configuration to the contact configuration, in which the arm 13 falls onto the base 11, and in the contact configuration In this case, the arm 13 diverges from the base 11 through the electrical contact between the carrier plate 14 and the boom 15 .

[0034] According to the invention, the disconnector 10 is characterized in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com