Membrane cartridge

A technology of membrane filtration and filter plate, which is applied in the direction of membrane, ultrafiltration, membrane technology, etc., can solve the problems of increased pressure loss and inability to obtain enough permeate, and achieve the effect of reducing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

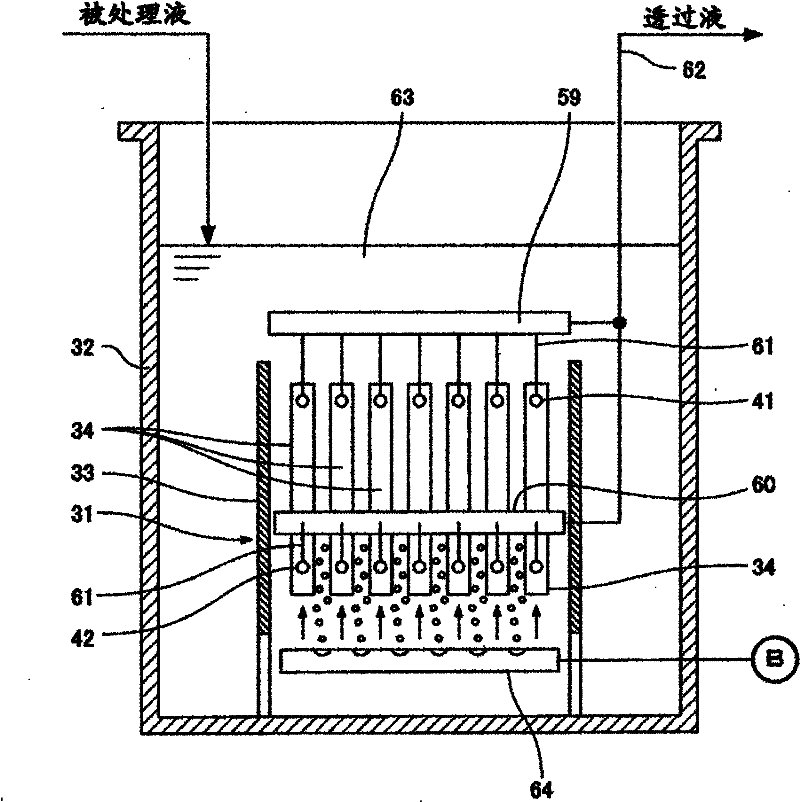

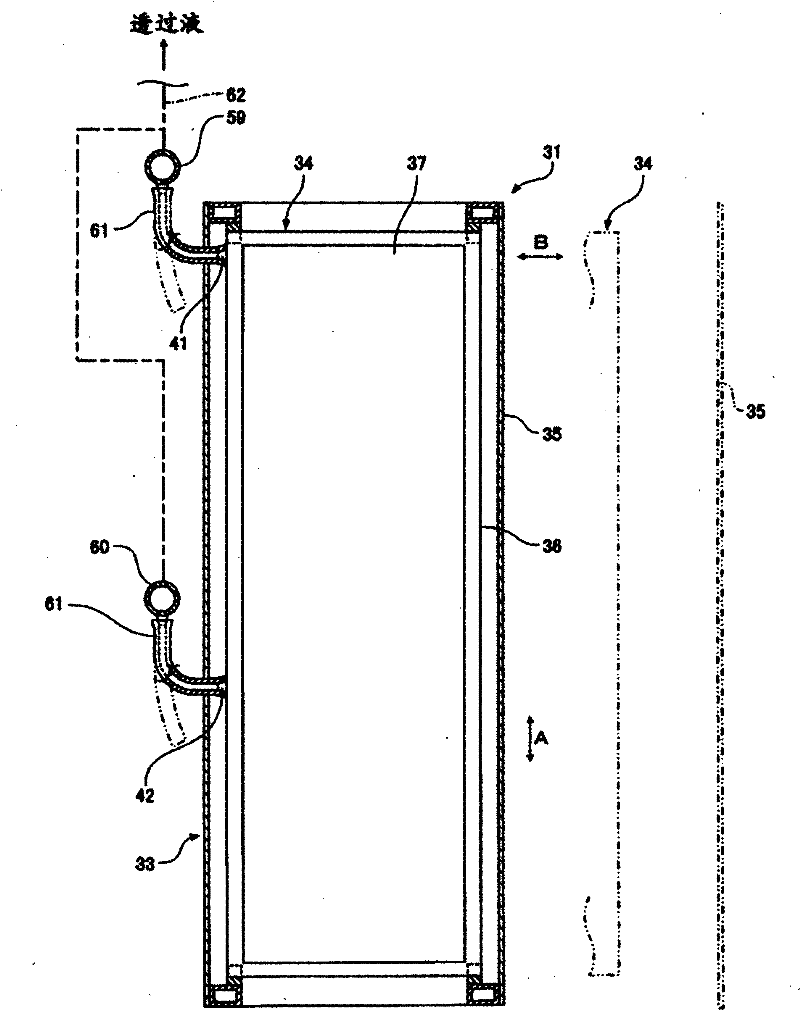

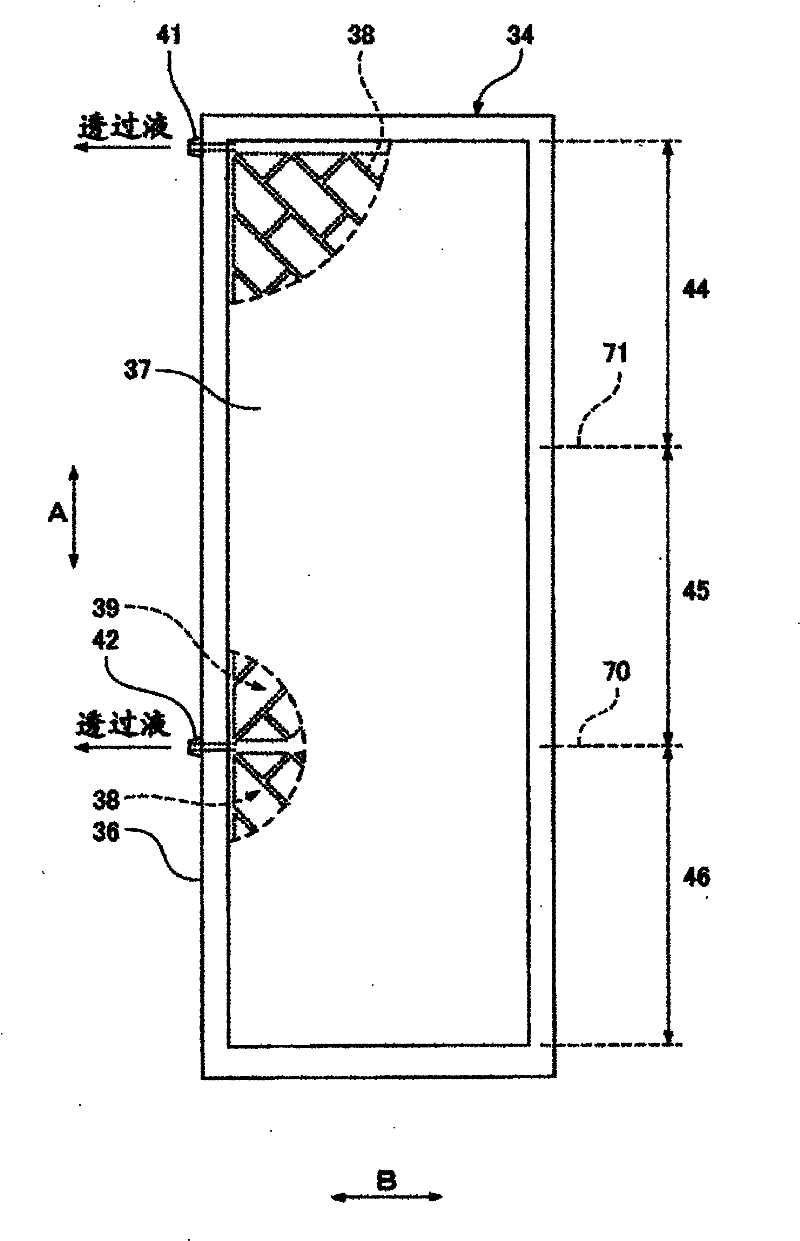

[0046] Below, refer to Figure 1 to Figure 6 The first embodiment of the present invention will be described.

[0047] like figure 1 , figure 2 As shown, a submerged membrane separation device 31 is installed inside a reaction tank 32 for treating sewage and the like with activated sludge. This membrane separation device 31 has: a quadrangular main body casing 33 with open upper and lower ends; a plurality of organic flat membrane type membrane cartridges 34 arranged in parallel at predetermined intervals in the inside of the main body casing 33; The air diffuser 64 provided below.

[0048] Further, the adjacent membrane cartridges 34 are arranged in parallel at a predetermined interval on the facing membrane surfaces. In addition, although the respective membrane cartridges 34 are spaced apart from each other at predetermined intervals, they may be in contact at least at side portions. In this case, the side surface of the main body case 33 may be opened, or the main b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com