Structural support of ball screw assembly

A technology of ball screw pair and support structure, which is applied in the direction of metal processing machinery parts, metal processing equipment, feeding devices, etc., and can solve problems such as accelerated bearing wear, uneven force on the inner and outer rings of bearings, and reduced service life of bearings. , to achieve the effect of improving assembly efficiency, ensuring balance, and reducing the number of disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0022] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

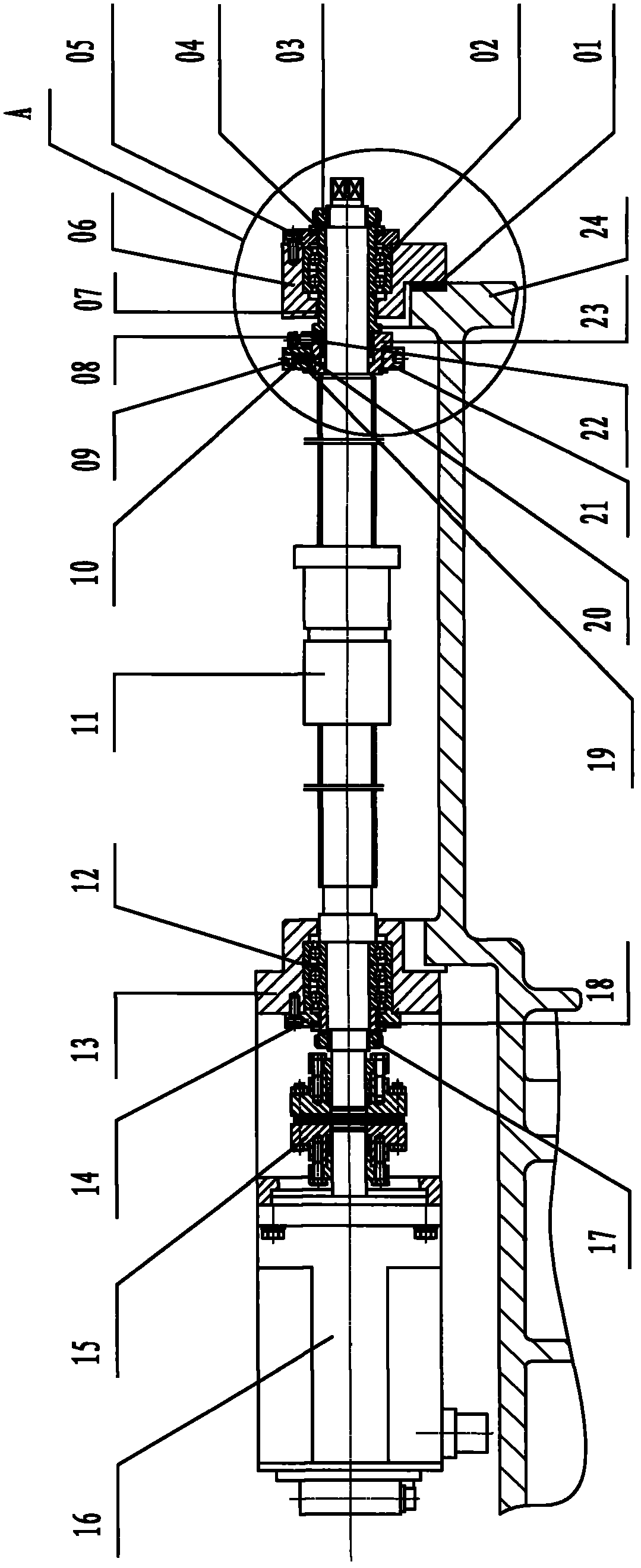

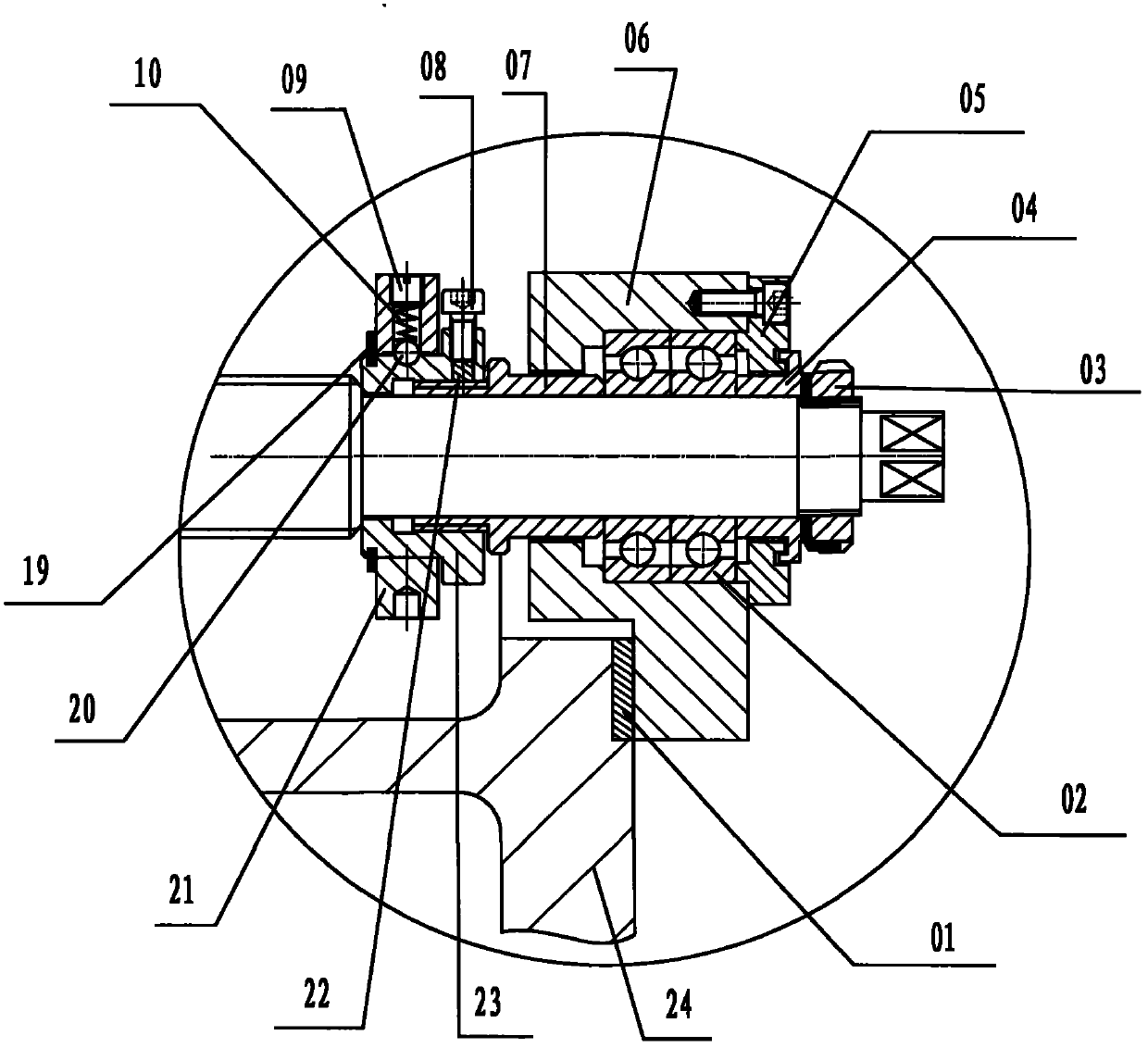

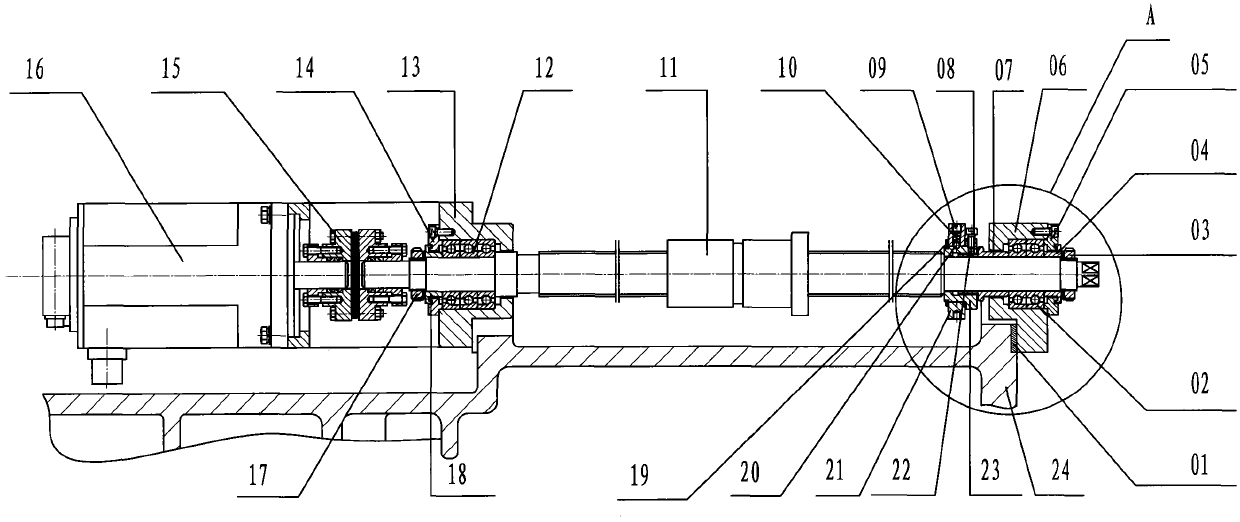

[0023] A ball screw pair support structure, such as figure 1 As shown, including base 24, motor support base 13 and bearing bracket 6 are fixedly installed on base 24, motor support base 13 is positioned at bearing bracket 6 left side, left end support bearing 12 is fixedly installed in motor support base 13, bearing bracket 6. The right end support bearing 2 is fixedly installed inside, the left end support bearing 12 and the right end support bearing 2 are installed with a ball screw pair 11 for relative rotation, and the ball screw pair 11 has a left step and a right step, and the left step is located at the right step. On the left side, the left end of the ball screw pair 11 extends to the left side of the left end support bearing 12, the right end of the ball screw pair 11 extends to the right side of the right end support bearing 2, and the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com