Krypton-xenon tower heating device and technology for heating krypton-xenon tower using same

A krypton-xenon and pipeline technology is applied to a krypton-xenon tower heating device and the technological field of using the device to heat a krypton-xenon tower, which can solve problems such as large heating of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

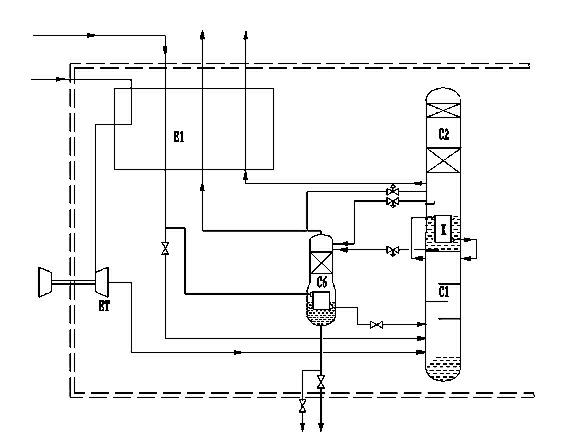

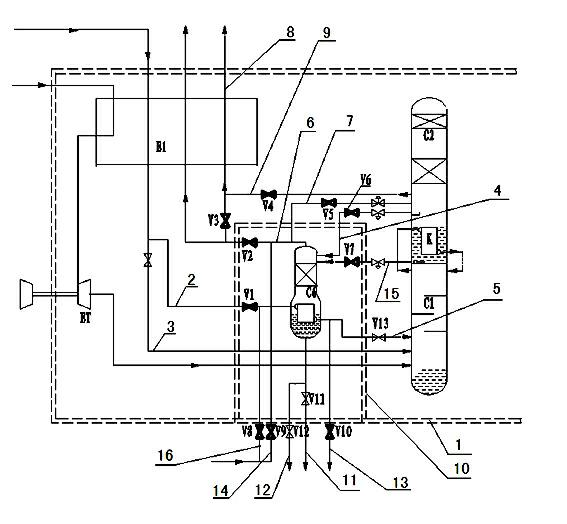

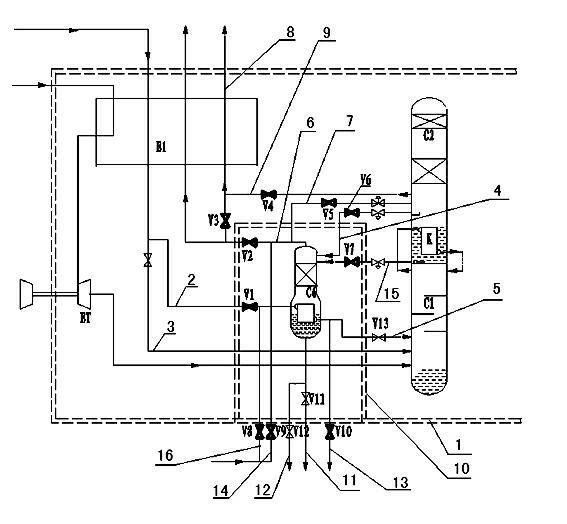

[0024] figure 1 It is a schematic diagram of the local structure of the traditional krypton-xenon tower heating device. Such as figure 2 As shown, a krypton-xenon tower heating device includes a cold box 1, a main heat exchanger E1 arranged in the cold box 1, and a krypton-xenon tower C6 connected to the first pipeline 2 passing through the main heat exchanger E1 , the lower tower C1 that is communicated with the second pipeline 3 that passes through the main heat exchanger E1, the upper tower C2 that is connected with the lower tower C1, the main condenser K that is arranged between the lower tower C1 and the upper tower C2, and is arranged on The third pipeline 4 and the ninth pipeline 15 between the upper tower C2 and the krypton-xenon tower C6, the fourth pipeline 5 with a valve V13 arranged between the krypton-xenon tower C6 and the lower tower C1, and the fourth pipeline 5 arranged in the krypton-xenon tower C6 The fifth pipeline 6 at the top, the sixth pipeline 7 com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com