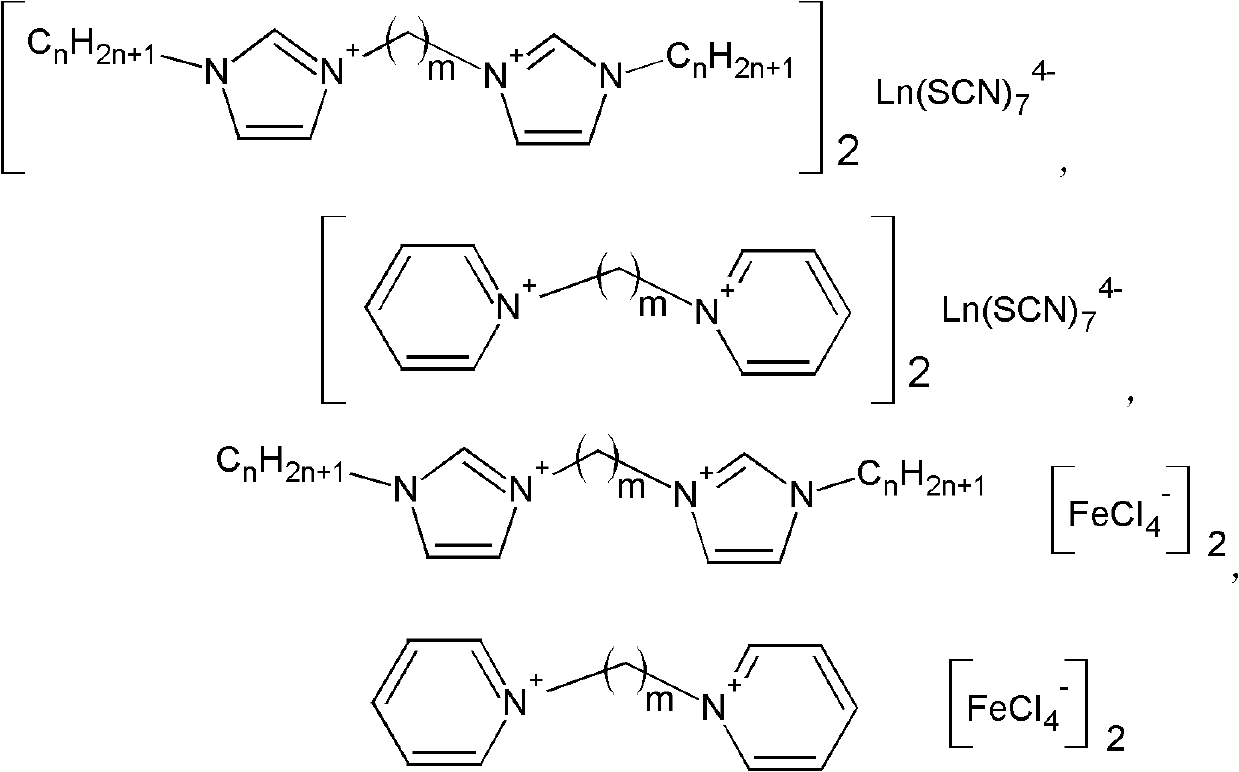

Bivalent cation magnetic ionic liquids and preparation method thereof

A magnetic ionic liquid, divalent cation technology, applied in magnetic liquids, organic chemistry and other directions, can solve the problems of single structure, uncontrollable magnetism, weak magnetism, etc., to achieve the effect of promoting application and solving uncontrollable magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

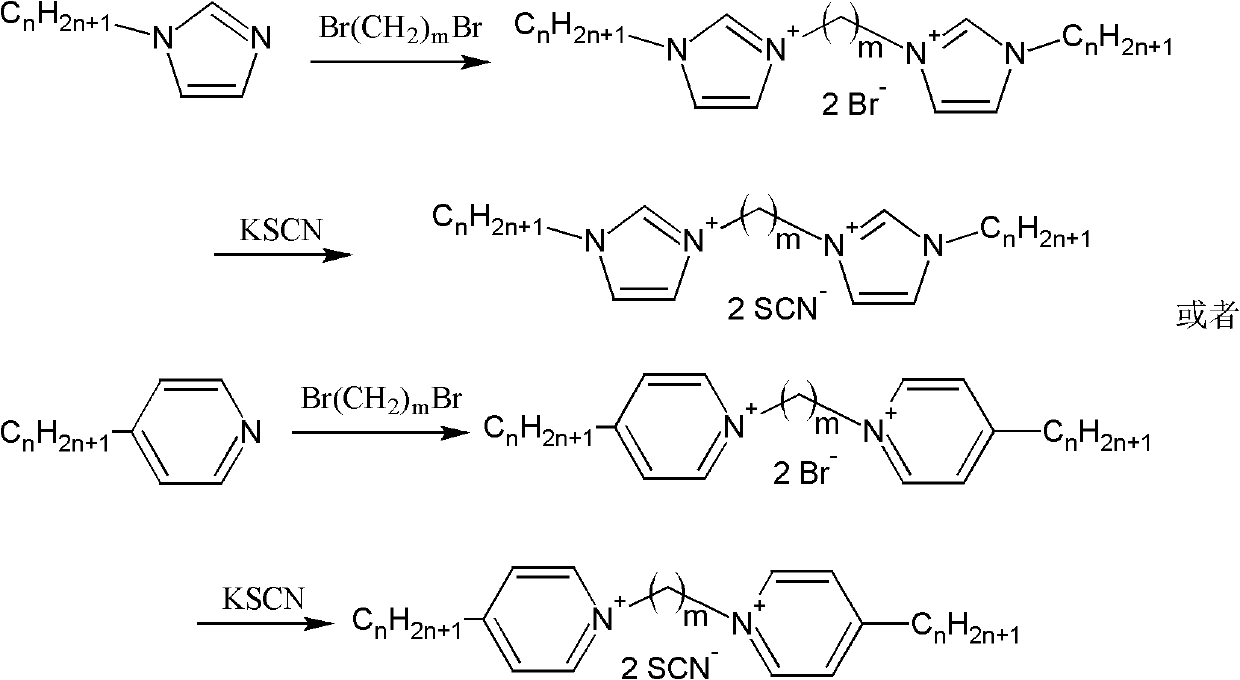

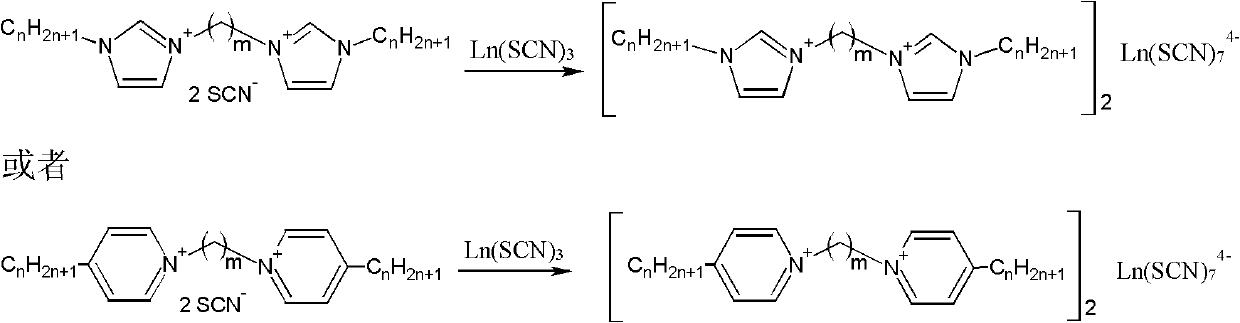

Method used

Image

Examples

Embodiment 1

[0020] Synthesis and characterization of:

[0021] (1) Slowly dissolve 8 g (0.0211 mol) of dysprosium trioxide in 20 g of 70% perchloric acid aqueous solution, stir and react at room temperature for 12 hours, remove water by rotary evaporation, and dry in vacuum for 48 hours to obtain Dy(ClO 4 ) 3 ·6H 2 O.

[0022] (2) Weigh 10 g (0.0532 mol) of 1,2-dibromoethane and 13.1011 g methylimidazole (0.1596 mol), place them in a single-necked flask, stir vigorously, and control the temperature at 70 ° C. After 24 hours of reaction, a large amount of White powder is formed, after cooling at low temperature, filter, and the filter cake is washed with 3×20ml acetone, and vacuum-dried for 24 hours to obtain a white powder product, [C 2 (mim) 2 ]Br 2 . 10g (0.0286mol) [C 2 (mim) 2 ]Br 2 Place the ionic liquid and 11.1042g (0.1143mol) KSCN in a 100ml single-necked flask, heat, stir and reflux at 80°C for 24 hours. After the reaction is complete, filter, distill off the acetone s...

Embodiment 2

[0026] Synthesis and characterization of:

[0027] (1) Slowly dissolve 8 g (0.0211 mol) of dysprosium trioxide in 20 g of 70% perchloric acid aqueous solution, stir and react at room temperature for 12 hours, remove water by rotary evaporation, and dry in vacuum for 48 hours to obtain Dy(ClO 4 ) 3 ·6H 2 O.

[0028] (2) Weigh 15 g (0.0695 mol) of 1,4-dibromoethane and 17.1113 g methylimidazole (0.2085 mol), place them in a single-necked flask, stir vigorously, and control the temperature at 70 ° C. After 24 hours of reaction, a large amount of White powder is formed, after cooling at low temperature, filter, and the filter cake is washed with 3×20ml acetone, and vacuum-dried for 24 hours to obtain a white powder product, [C 4 (mim) 2 ]Br 2 . 10g (0.0263mol) [C 4 (mim) 2 ]Br 2 Place the ionic liquid and 10.2292g (0.1052mol) KSCN in a 100ml single-necked flask, heat, stir and reflux at 80°C for 24 hours. After the reaction is complete, filter, distill off the acetone s...

Embodiment 3

[0032] Synthesis and characterization of:

[0033] (1) Slowly dissolve 8 g (0.0211 mol) of dysprosium trioxide in 20 g of 70% perchloric acid aqueous solution, stir and react at room temperature for 12 hours, remove water by rotary evaporation, and dry in vacuum for 48 hours to obtain Dy(ClO 4 ) 3 ·6H 2 O.

[0034] (2) Weigh 10 g (0.0410 mol) of 1,6-dibromoethane and 10.0980 g methylimidazole (0.1230 mol), place them in a single-necked flask, and keep the temperature at 70°C under vigorous stirring. After 24 hours of reaction, a large amount of White powder is formed, after cooling at low temperature, filter, and the filter cake is washed with 3×20ml acetone, and vacuum-dried for 24 hours to obtain a white powder product, [C 6 (mim) 2 ]Br 2 . 10g (0.0245mol) [C 6 (mim) 2 ]Br 2 Place the ionic liquid and 9.5236g (0.0980mol) KSCN in a 100ml single-necked flask, heat, stir and reflux at 80°C for 24 hours. After the reaction is complete, filter, distill off the acetone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com