Spacer dispensing device, spacer dispensing method and producing method of liquid crystal panel

A substrate and platen technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of easy charging rigidity, the inability of spacers to evenly distribute resin-made substrates, and the difficulty of evenly disposing spacers, etc., and achieve the effect of preventing static electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

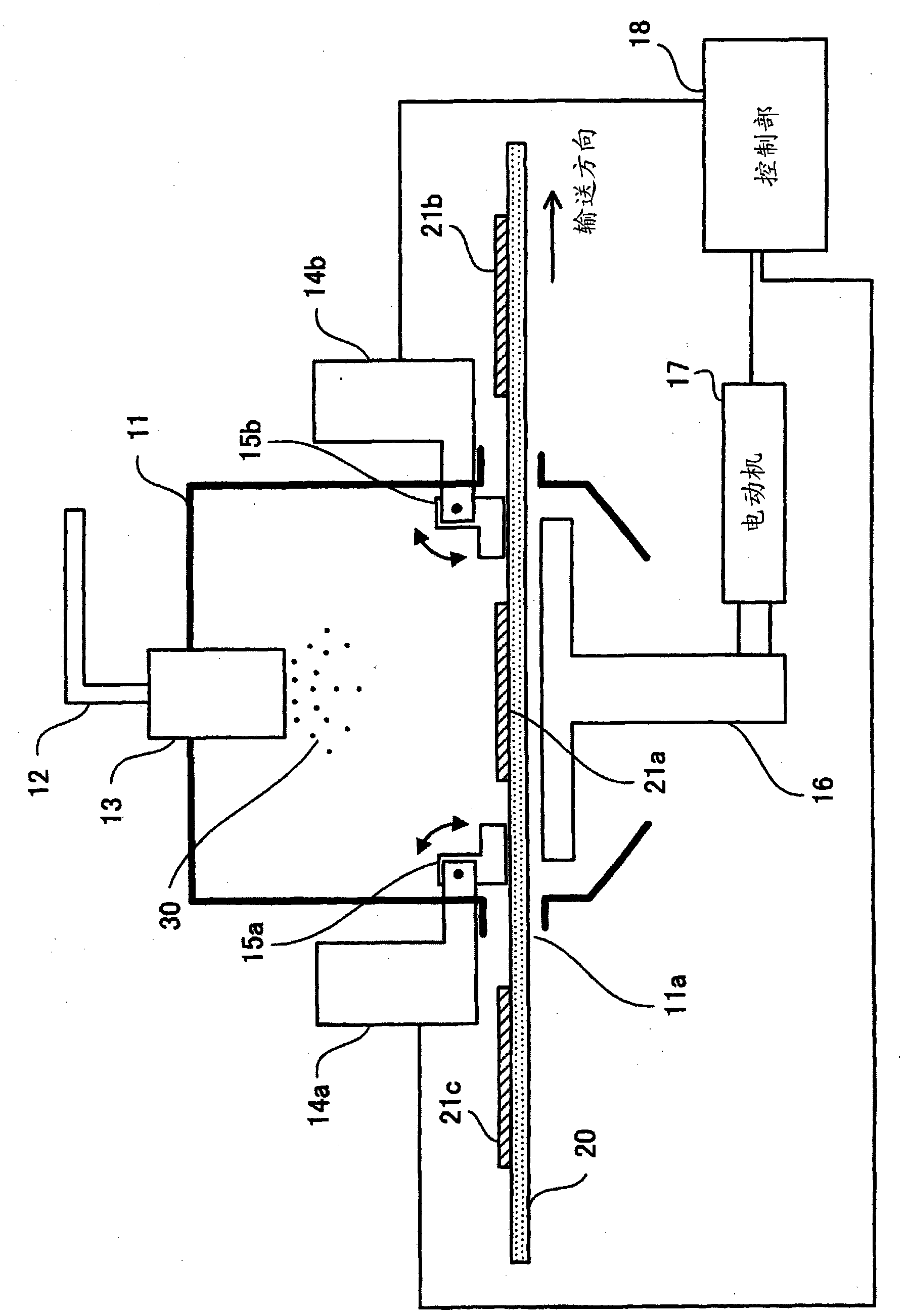

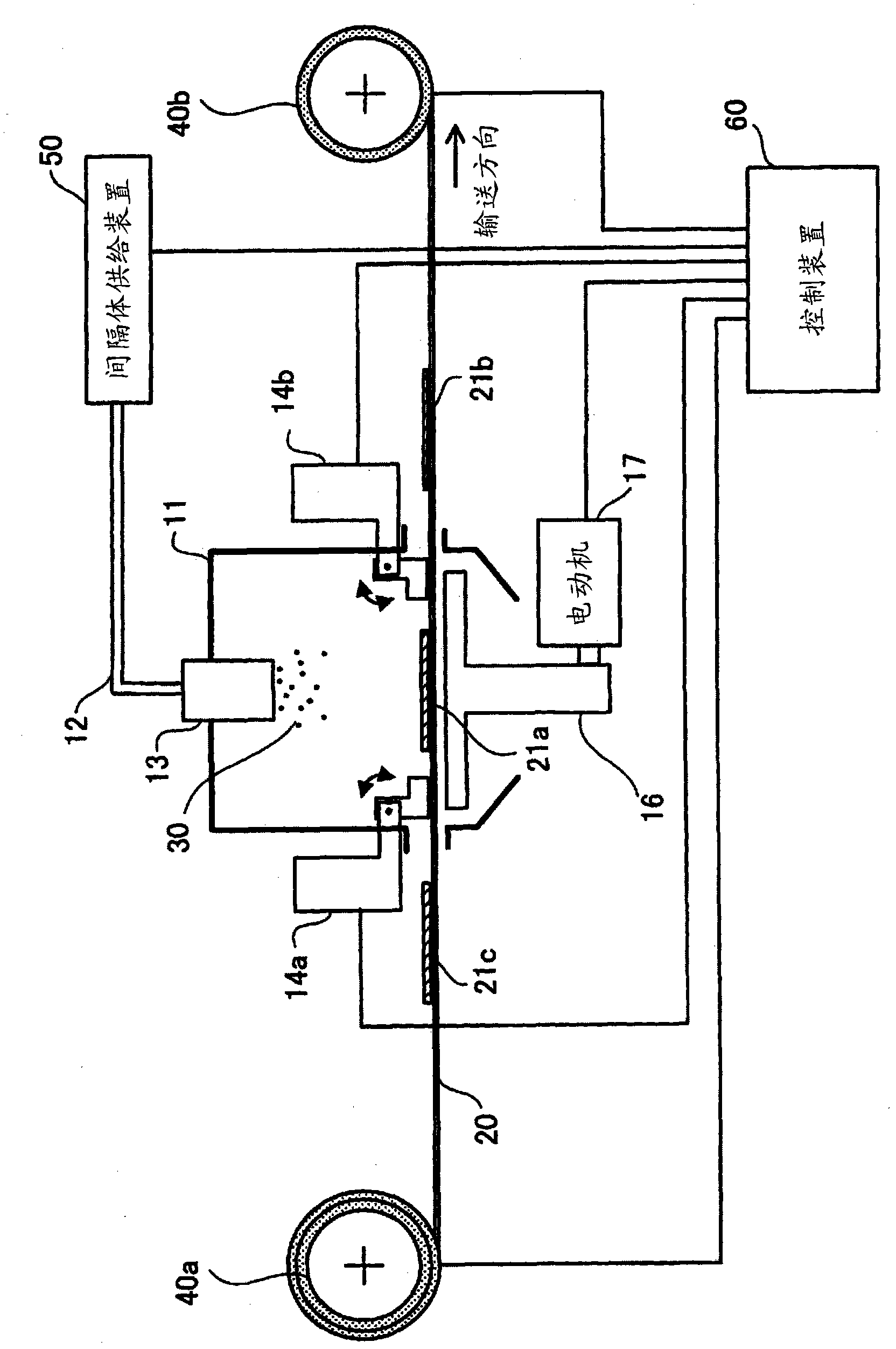

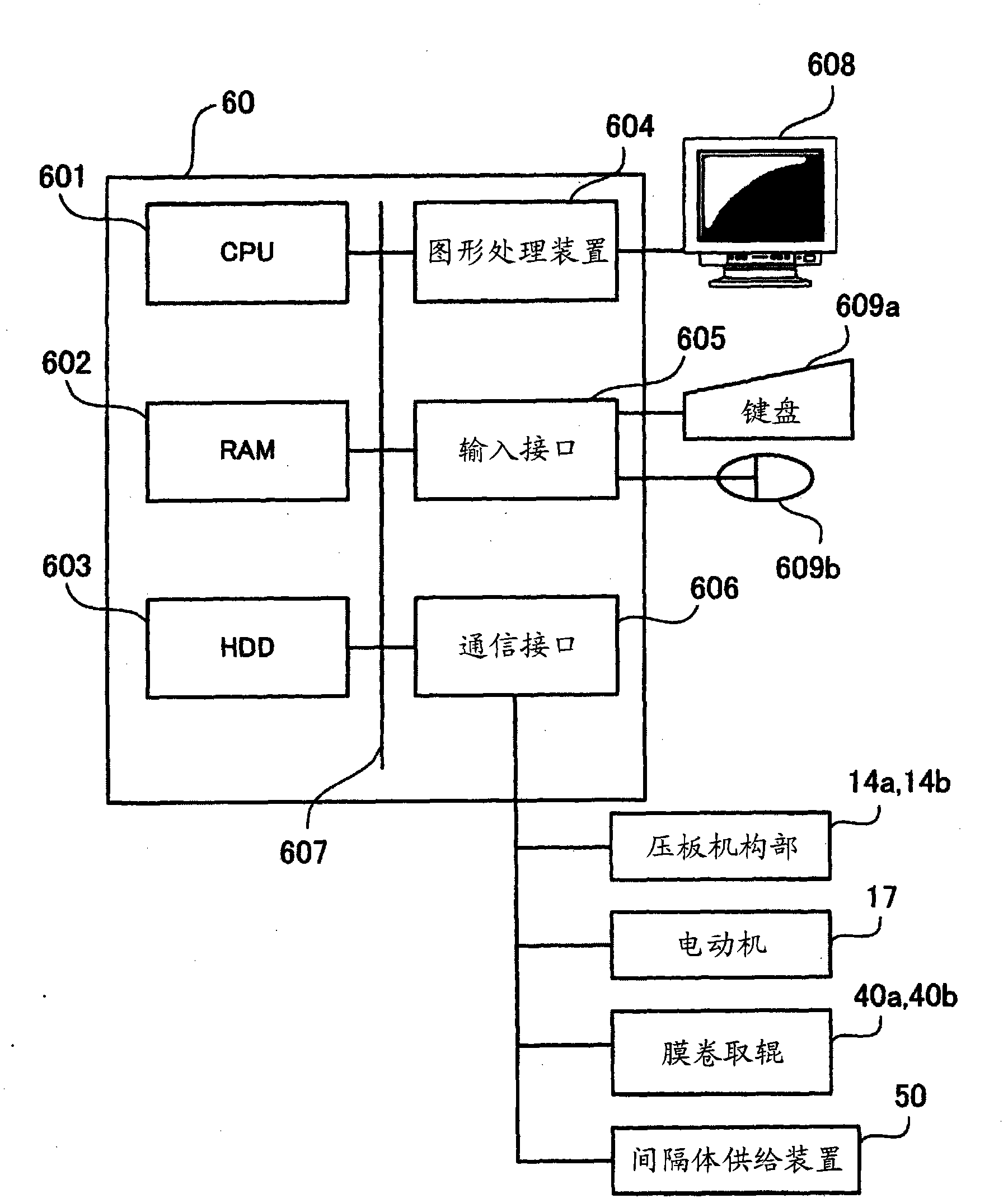

[0034] figure 1 It is a figure which shows the structural example of the spacer spraying apparatus of embodiment.

[0035] The spacer spraying device performs a spacer spraying process on a film substrate 20 in which individual electrode patterns are continuously formed on a film-like thin resin substrate. The spacer distributing device has an outer shell container 11, a pipe 12 for conveying the spacer 30 into the container 11, a nozzle 13 for distributing the spacer 30, a platen mechanism part 14a, 14b for pressing the film substrate 20, and an operation for placing the film substrate 20. Table 16, motor 17 for moving table 16, and control unit 18.

[0036] The container 11 is the casing of the spacer spreading device, and can make the inside of the spacer spreading device airtight or close to airtight. An exhaust port 11 a for exhausting the compressed air releas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com