Monitoring system of coal bed gas screw pump well

A monitoring system and screw pump technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of limited well site conditions, untimely management, high failure rate, etc., to reduce workover time and facilitate The effect of maintenance and prevention of pump burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

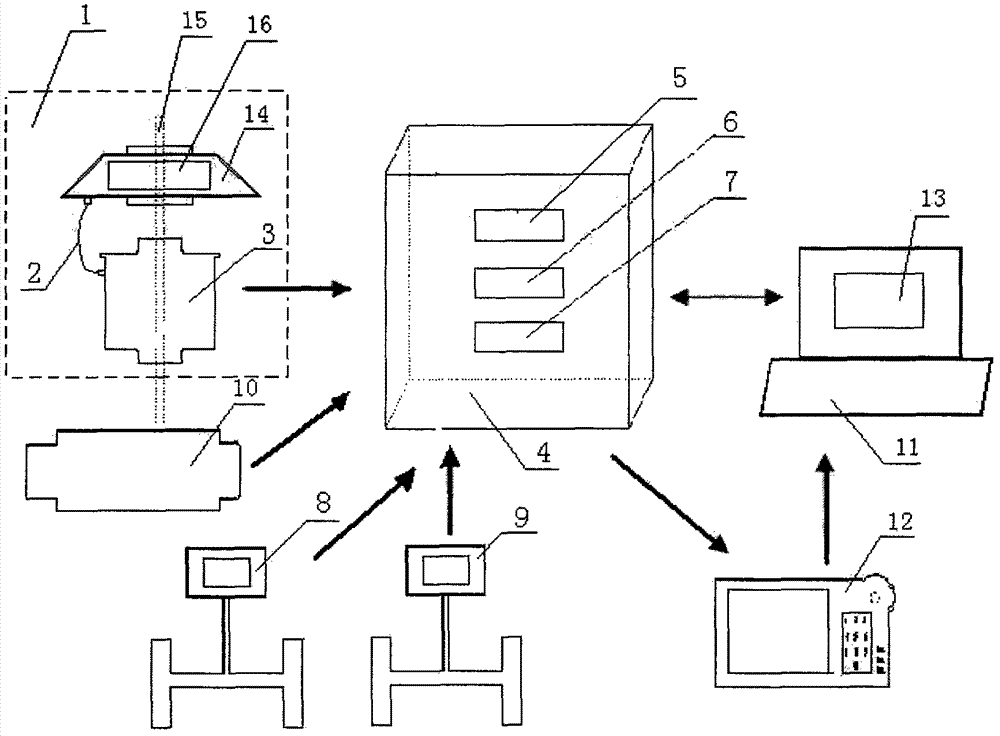

[0010] Such as figure 1 As shown in , the coalbed methane screw pump well monitoring system includes: solar control device 1, cable 2, sensor 3, multi-parameter recorder 4, current transformer 5, electrical parameter collector 6, wireless controller 7, and coalbed methane meter 8. Water meter 9, liquid level automatic monitor 10, central control computer 11, portable data collector 12, monitoring and diagnosis software 13, solar control device shell 14, screw pump screw 15, polysilicon battery board 16.

[0011] The solar control device 1 is installed on the top of the screw 15 of the CBM screw pump, and is connected with the torsional pressure sensor 3, which is also fixed on the rotating polished rod through the cable 2, and collects the torque, axial force load and polished rod speed of the polished rod in real time. After being processed by the control circuit in 1, it is sent to the multi-parameter recorder 4 in a wireless manner.

[0012] The multi-parameter recorder 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com