Method for making electromagnetic label

A manufacturing method and magnetic label technology, which are applied in the direction of electrical alarms and the like, can solve the problems of complex processing technology and low yield, and achieve the effects of simple technology, low cost and convenient processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

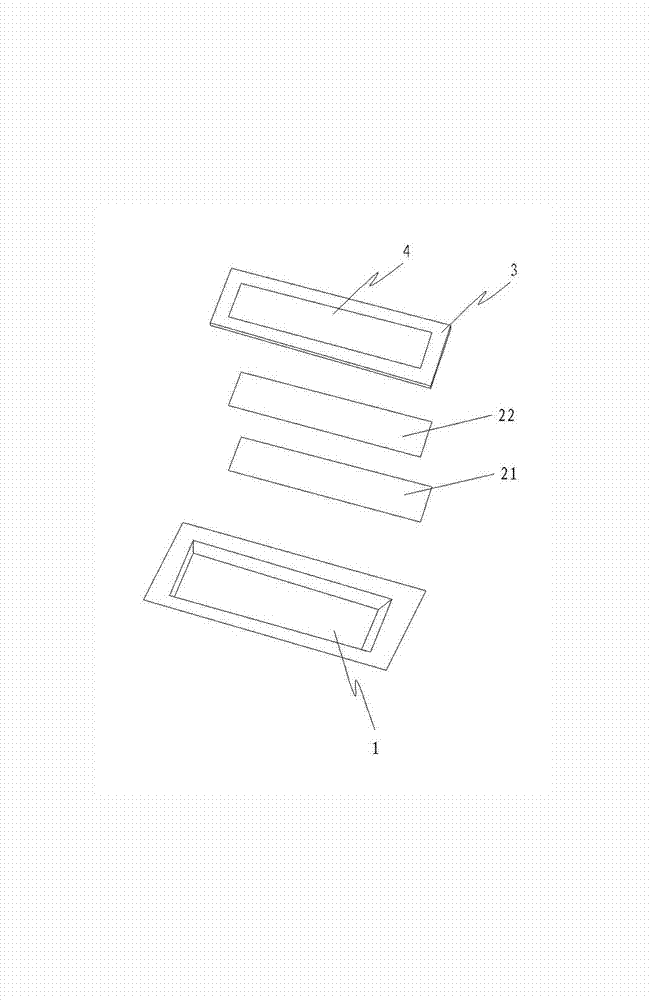

[0022] Embodiment: a kind of electronic magnetic label, such as figure 1 Shown, by bottom box 1, two resonant sheets 21,22-biasing sheet 4 and two thin films 3 of clamping this biasing sheet, a kind of electronic magnetic label manufacturing method comprises the following steps: resonating sheet is sliced and transferred to the end Inside the box, the bottom box 1 has a plurality of divisible cavities 10, each cavity absorbs two resonant plates 21, 22, the bottom box has 5X10 divisible cavities, the bottom box absorbs Each of the cavities on the tablet sucks a resonant tablet once, and then sucks the tablet once so that there are two resonant tablets in the 50 cavities. The frequency of the above-mentioned resonant tablets is 58kHz;

[0023] Bias 4 slices, heat treatment of each sheet-shaped bias and test br value of 1.4T, then attach and clamp between the grease films 3 on both sides, the bias on the grease film and the cavity on the bottom box are One-to-one correspondenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com