BGA (Ball Grid Array) component repairing method and fixture

A rework and component technology, applied in the field of BGA component rework methods and rework fixtures, can solve the problems of low rework efficiency of rework fixtures, and achieve the effects of improving rework efficiency, ensuring disassembly quality, and improving disassembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

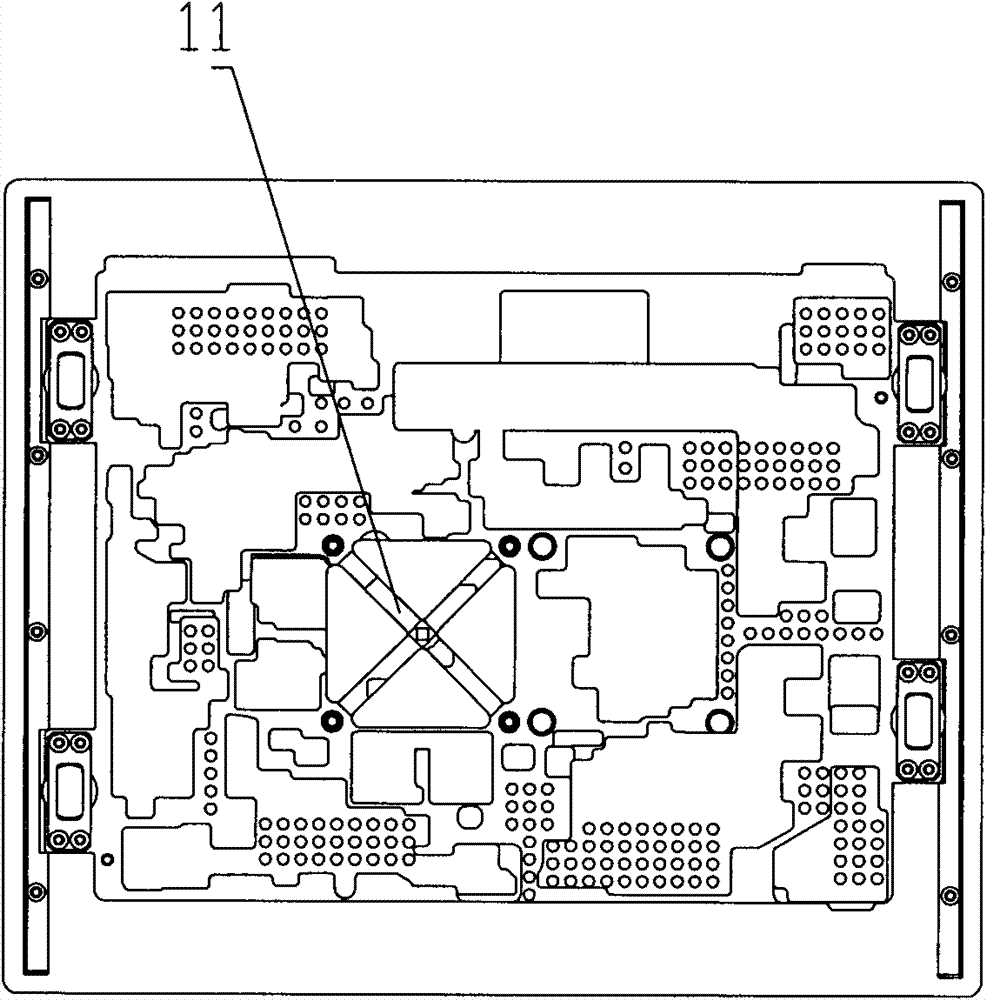

[0042] Such as Figure 6 As shown, the first embodiment of the BGA component repair method of the present invention includes:

[0043] Step S602: placing the PCB board on the rework chassis and fixing it;

[0044] Step S604: Cover and fix the reworked upper cover on the reworked chassis, so that the reworked upper cover and the reworked chassis tightly package the PCB board, and make the BGA components on the PCB board that need to be reworked from the hollow window of the reworked upper cover to exposed;

[0045] Step S606: the reworked upper cover and the reworked chassis packaged in one body are reflow soldered, so that the BGA components to be reworked are separated from the PCB board;

[0046] Step S608: remove the BGA components to be repaired from the PCB board, separate the repaired upper cover from the repaired chassis, and take out the PCB board;

[0047] Step S610: using a mounter to paste qualified BGA components on the PCB, and fixing the PCB on the rework chas...

Embodiment 2

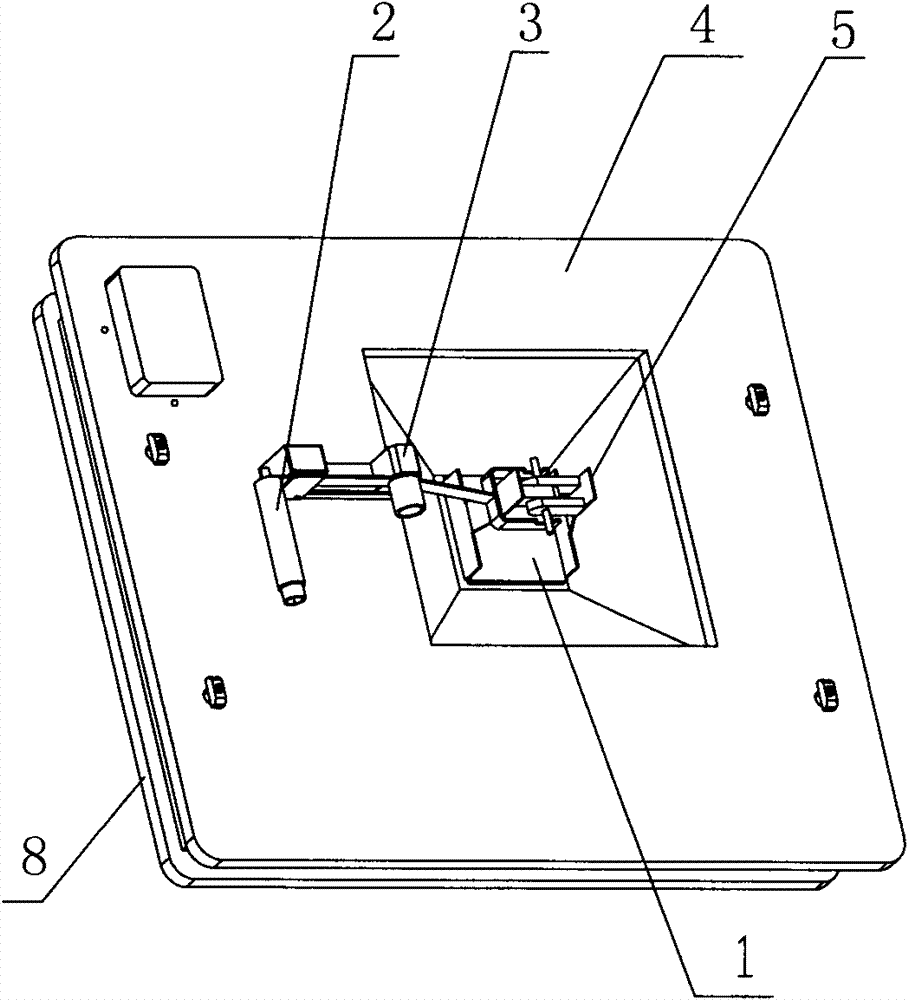

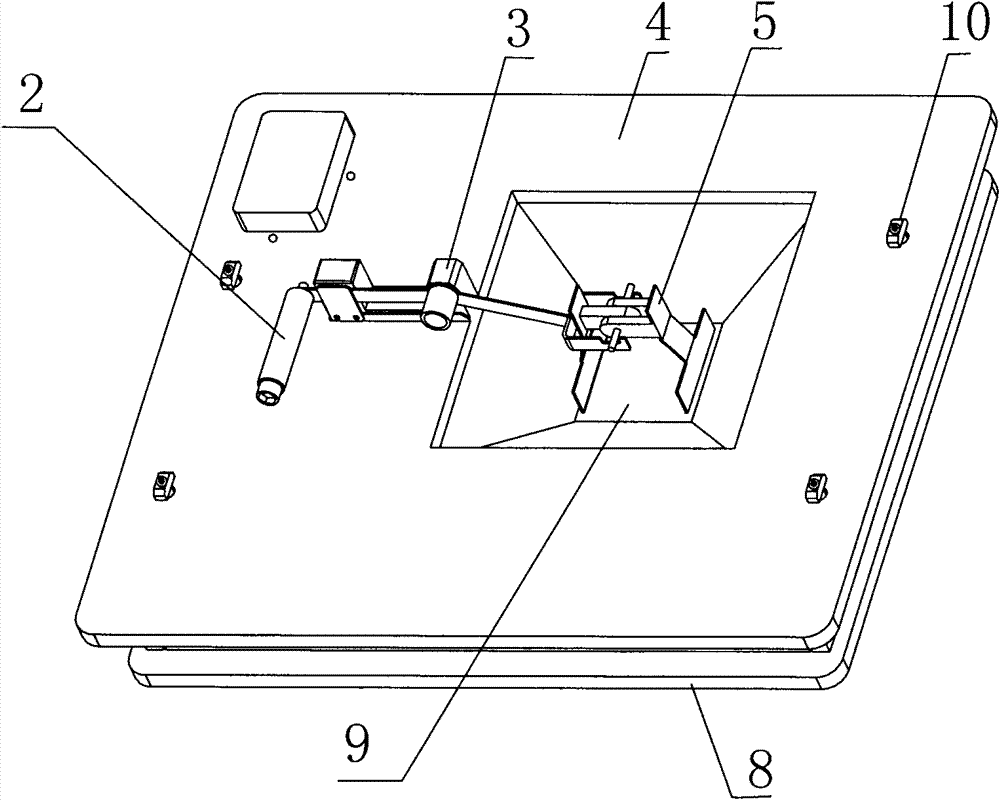

[0052] Such as Figure 7 As shown, the second embodiment of the BGA component repair method of the present invention includes:

[0053] Step S702: placing the PCB board on the rework chassis and fixing it;

[0054] Step S704: Cover and fix the rework upper cover on the rework chassis, so that the rework upper cover and the rework chassis tightly package the PCB board, and make the BGA components on the PCB board that need to be reworked from the hollow window of the rework upper cover to exposed;

[0055] Step S706: pre-clamp the collet of the disassembly clip on the BGA component to be repaired, and clamp the support of the disassembly clip on the rework cover;

[0056] Step S708: reflow soldering the packaged reworked upper cover and reworked chassis to separate the BGA components to be reworked from the PCB board;

[0057] Step S710: Press down the lifting arm of the removal clip, the connecting rod converts the reciprocating motion of the lifting arm into the clamping m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com