Diamond grinding tool convenient for replacing tool bits

A diamond and cutter head technology, which is applied in the field of processing abrasive tools, can solve the problems of cumbersome welding processing operations, small welding surface between the cutter head and the disc body, and insufficient connection strength, so as to achieve good social and economic benefits and save welding time and cost, fast and easy disassembly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described with reference to the drawings and specific embodiments.

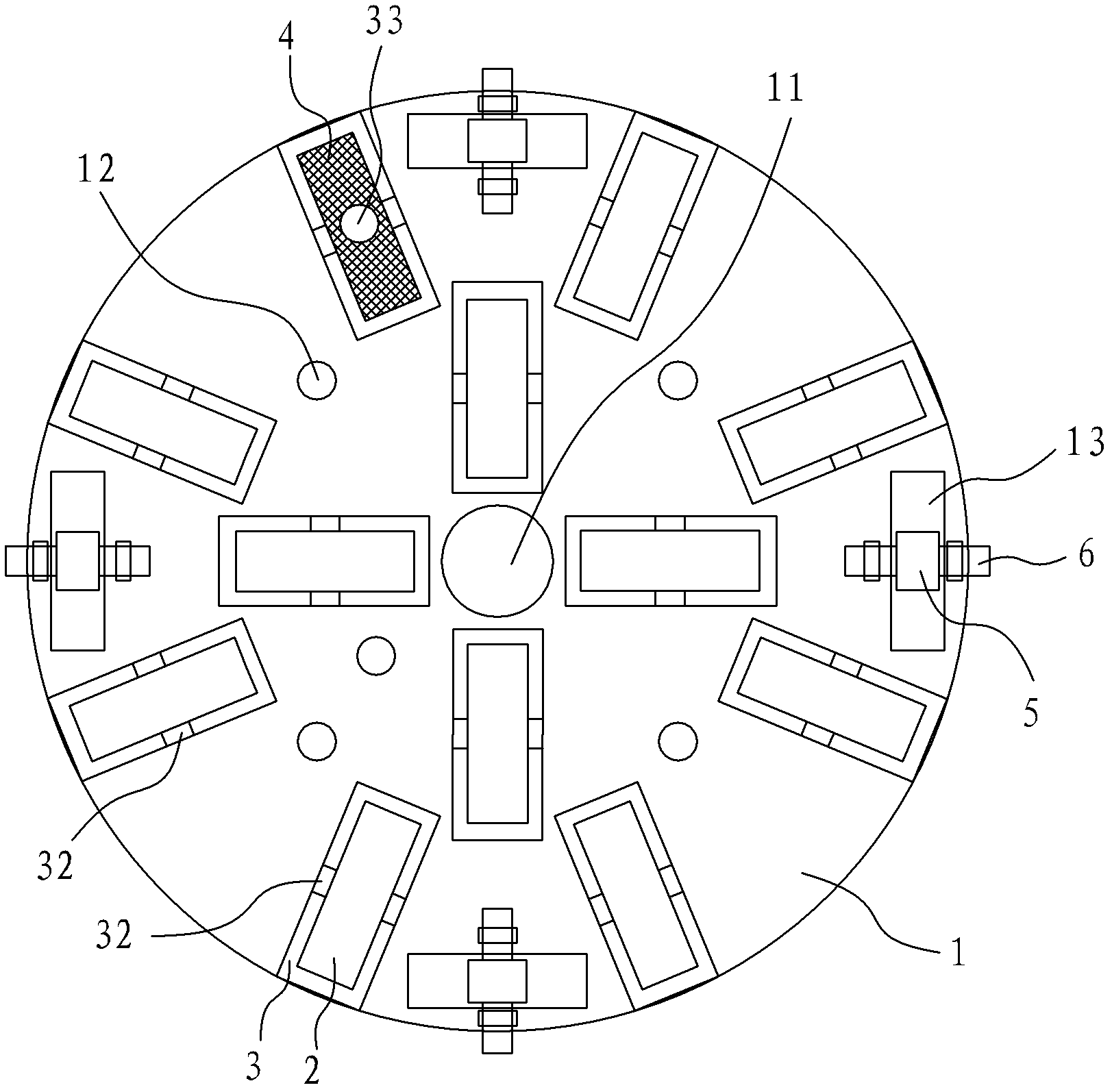

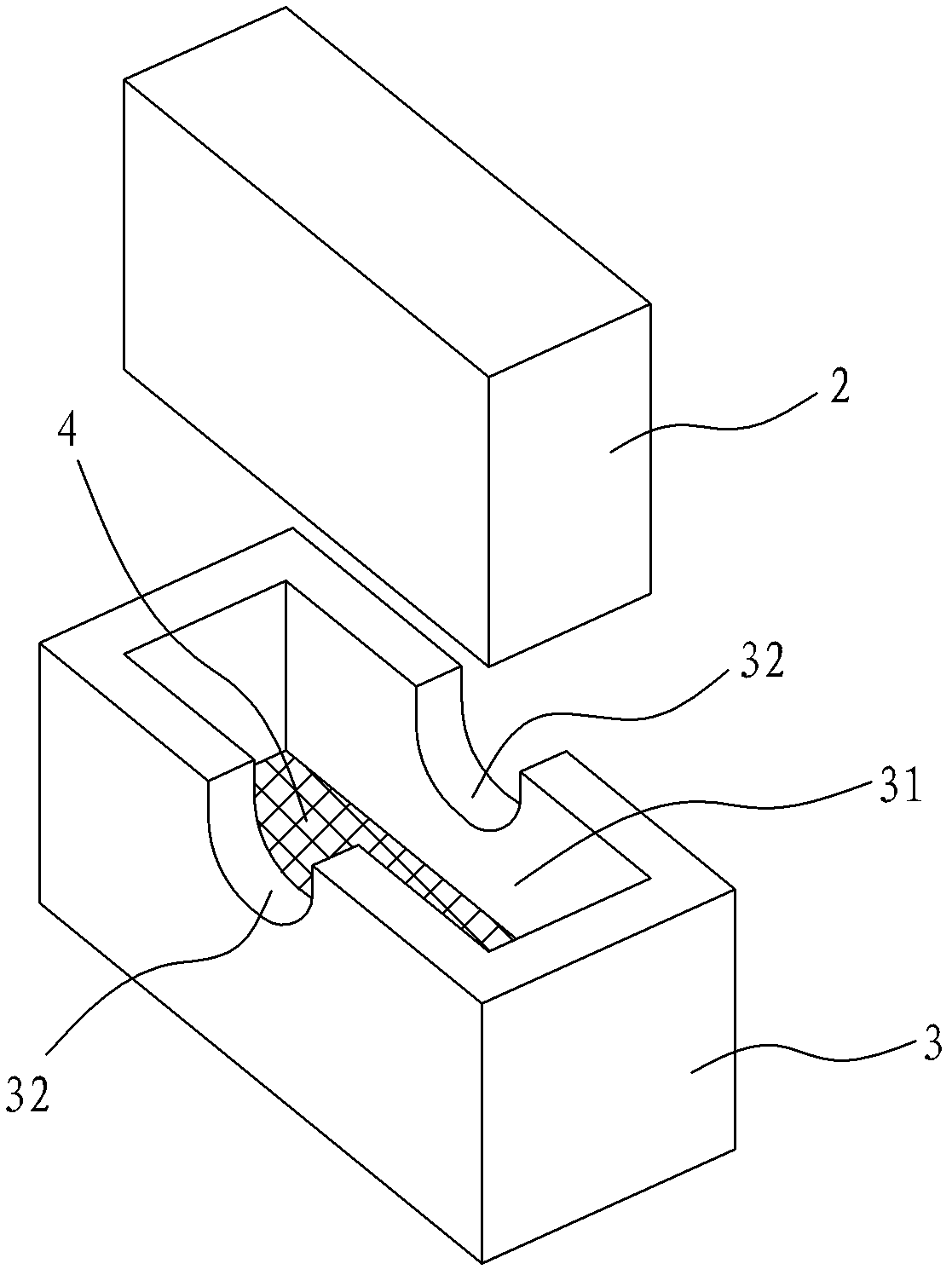

[0014] reference figure 1 , figure 2 , The embodiment of the present invention discloses a diamond grinding tool for easy replacement of cutter heads, including a disc body 1 and a cutter head 2. The disc body 1 is a circular sheet body, and the center of the disc body 1 is provided with a shaft hole 11, the shaft There are a plurality of mounting fixing holes 12 around the hole 11 to facilitate the fixed connection between the disc body 1 and the mill; the working surface of the disc body 1 is evenly distributed with a total of 12 cutter head fixing seats 3 in the inner and outer rings, including 8 The cutter head fixing seats 3 are evenly distributed on the outer ring of the working surface of the disc body 1, and four cutter head fixing seats 3 are evenly distributed on the inner ring of the working face of the disc body 1. Each of the cutter head fixing seats 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com