Thyristor converter valve tower for high voltage direct current transmission

A technology of thyristor converter valve and high-voltage direct current transmission, which is applied in the direction of circuits, electrical components, electric solid devices, etc., can solve the short circuit hazard of lower components, reduce the service life of thyristor converter valve valve tower, etc., and improve the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

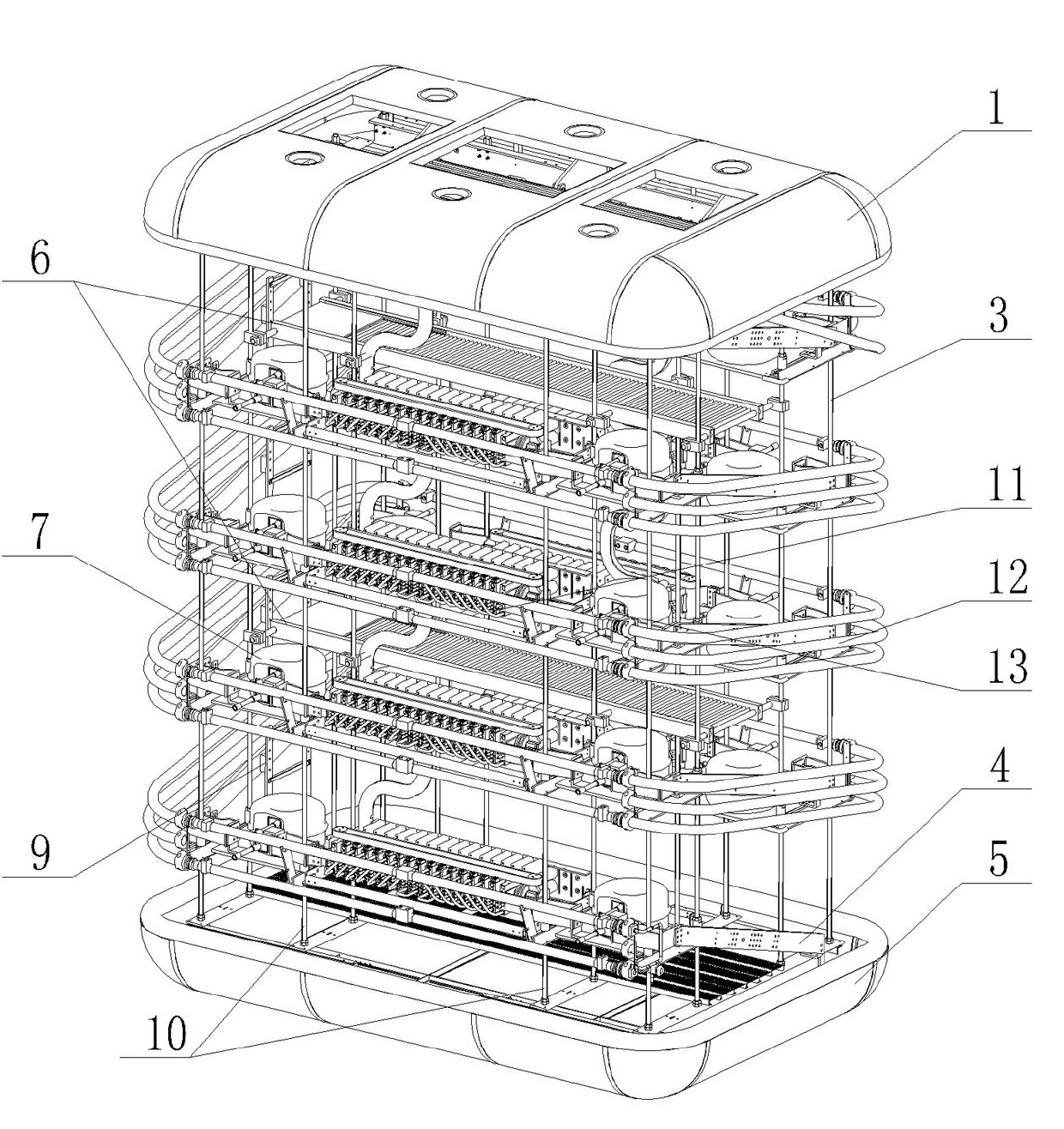

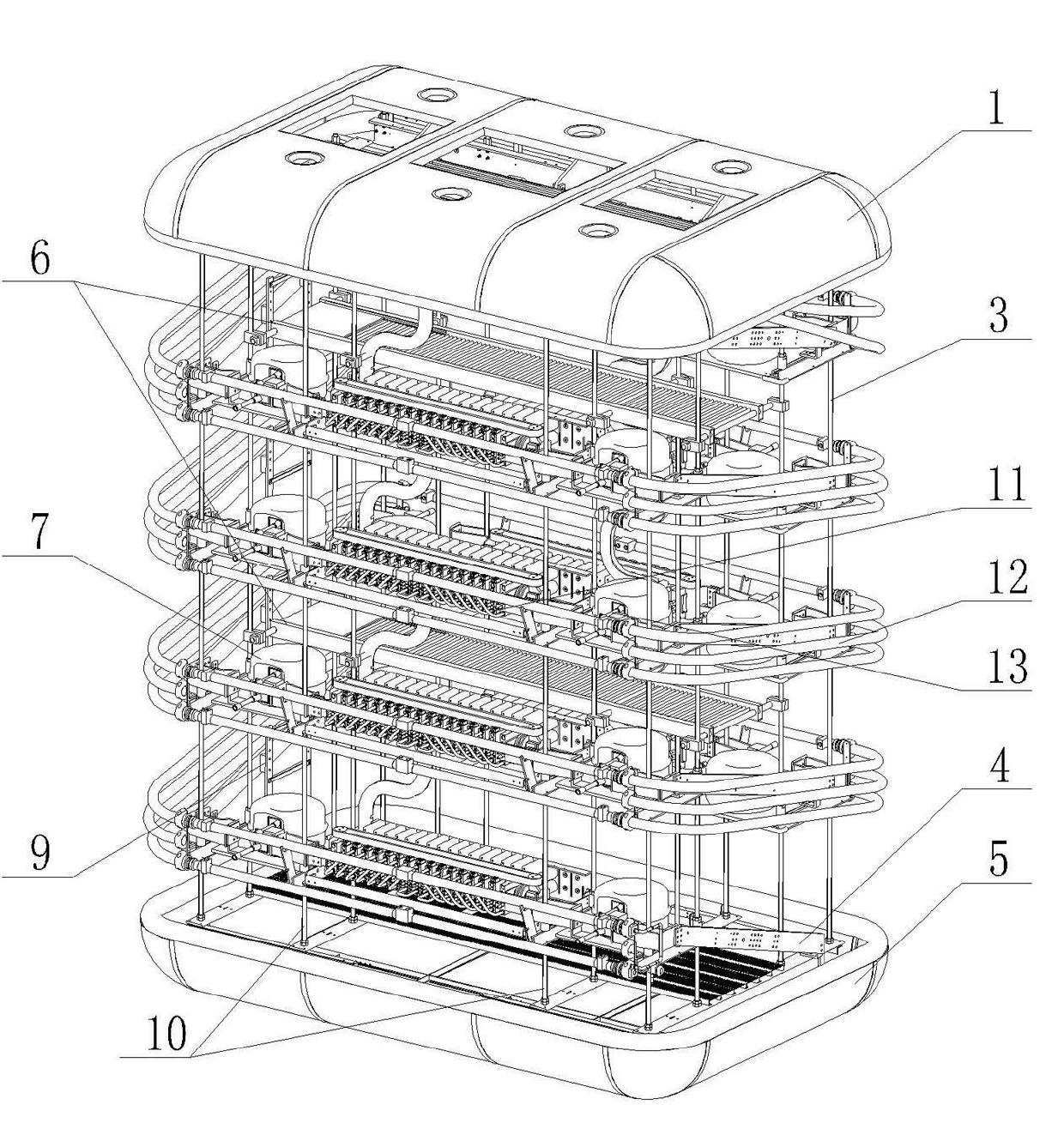

[0012] Example figure 1 Shown: a thyristor converter valve tower for high-voltage direct current transmission, the thyristor converter valve tower includes an insulating support frame 3, and the insulating support frame 3 includes insulating screws arranged side by side along the length direction of the thyristor converter valve tower 10. At least two valve modules 11 and reactor modules 7 are arranged side by side at intervals along the vertical direction on the insulating support frame 3. The valve tower of the thyristor converter valve also includes a water cooling system for cooling the thyristor and auxiliary components. The water-cooling system described above includes a cooling water main pipeline 12 and a cooling water pipeline 13. The cooling water main pipeline 12 is arranged around the outer side of the corresponding valve module 3 from top to bottom, and the cooling water main pipeline 12 faces toward the inner side of the cooling water main pipeline 12 ring. Direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com