Implement having a hybrid drive

A technology of tools and energy storage devices, applied in the direction of power devices, hybrid vehicles, pneumatic power devices, etc., can solve problems such as high fuel consumption and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

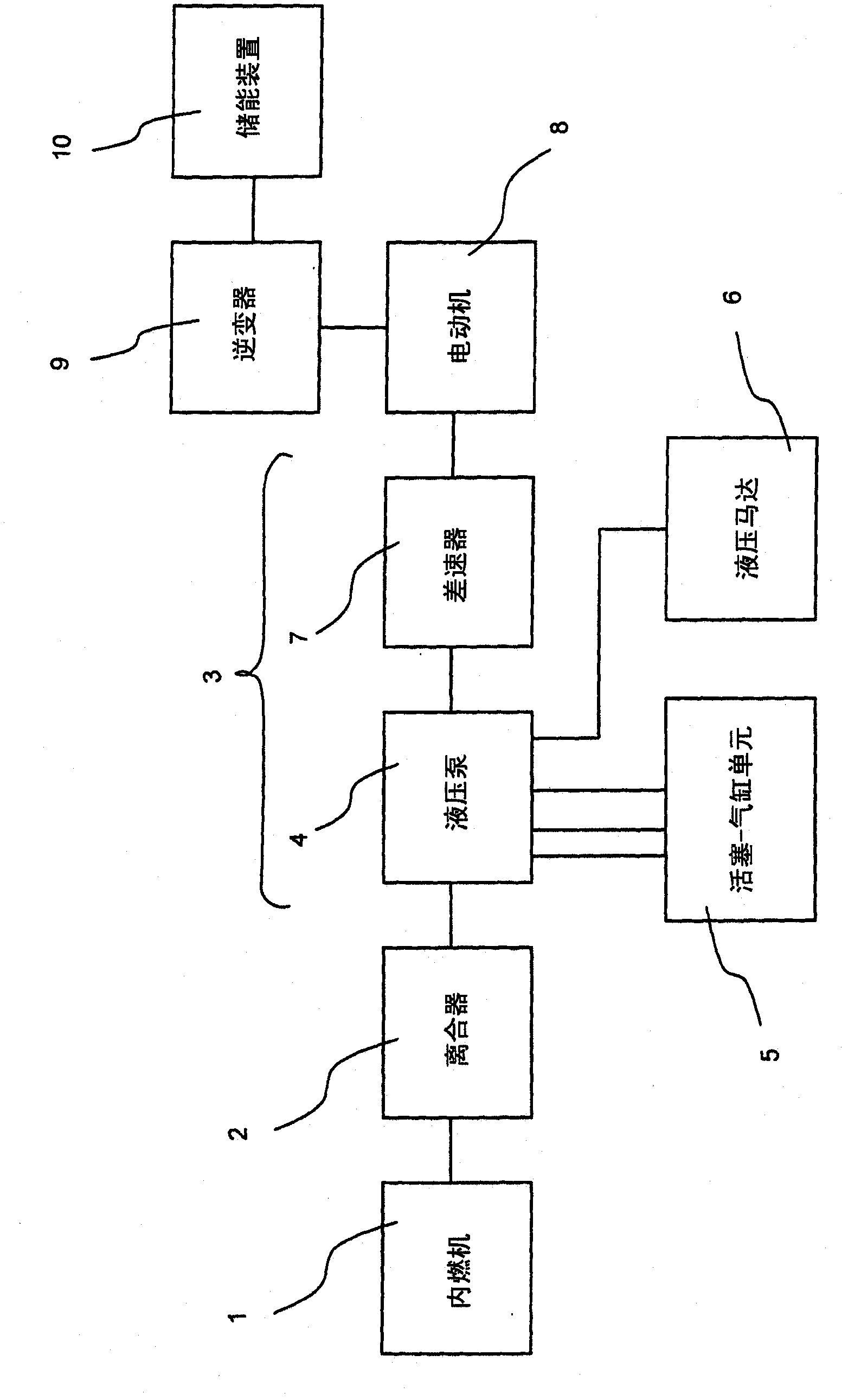

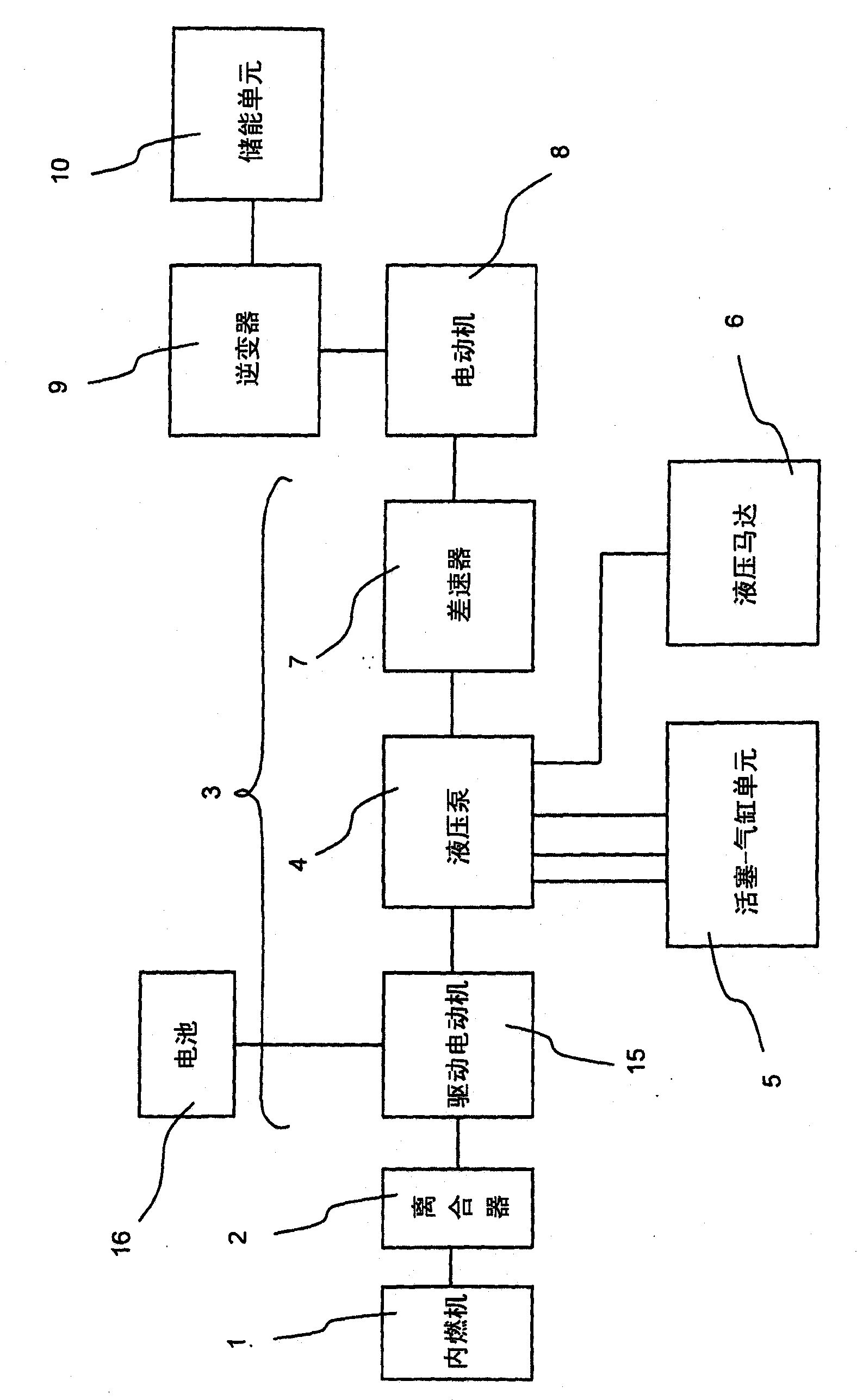

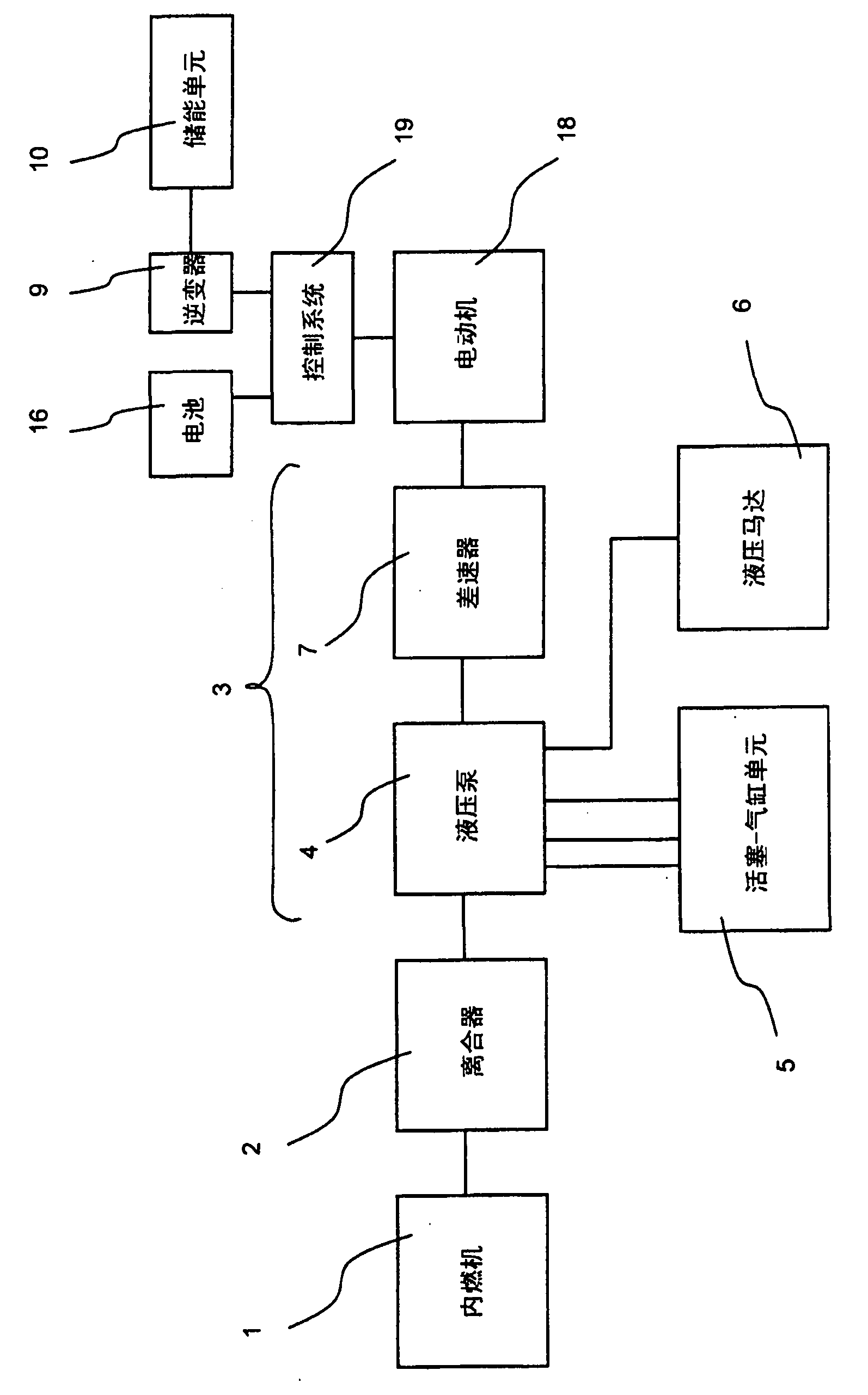

[0060] figure 1 The principle structure of the mixing system of the tool according to the invention is shown schematically.

[0061] The internal combustion engine 1 is coupled via a clutch 2 to a main drive train 3 , which represents the operative coupling. By means of a clutch 2 , which can be controlled via a control device (not shown), the internal combustion engine 1 can be connected to or disconnected from the main drive train 3 as required. This will be further elaborated below.

[0062] In the main drive train 3 there are one or more hydraulic pumps 4 which are driven by the internal combustion engine 1 in normal operation in order to convey and pressurize hydraulic fluid (hydraulic oil) in a known manner in the hydraulic system. The hydraulic pump 4 is correspondingly connected to one or more piston-cylinder units 5 . On its side, the piston-cylinder unit 5 is again used, for example, to raise or lower the arms of an excavator or loader or to move a bucket.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com