Repair method and repair device for wall surface of coke oven chamber at bottom edge thereof

A technology for carbonization chambers and coke ovens, which is applied to coke ovens, furnaces, furnace components, etc., and can solve the problem of not being able to repair the entire area of the damaged part 115 of the bottom edge of the furnace, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

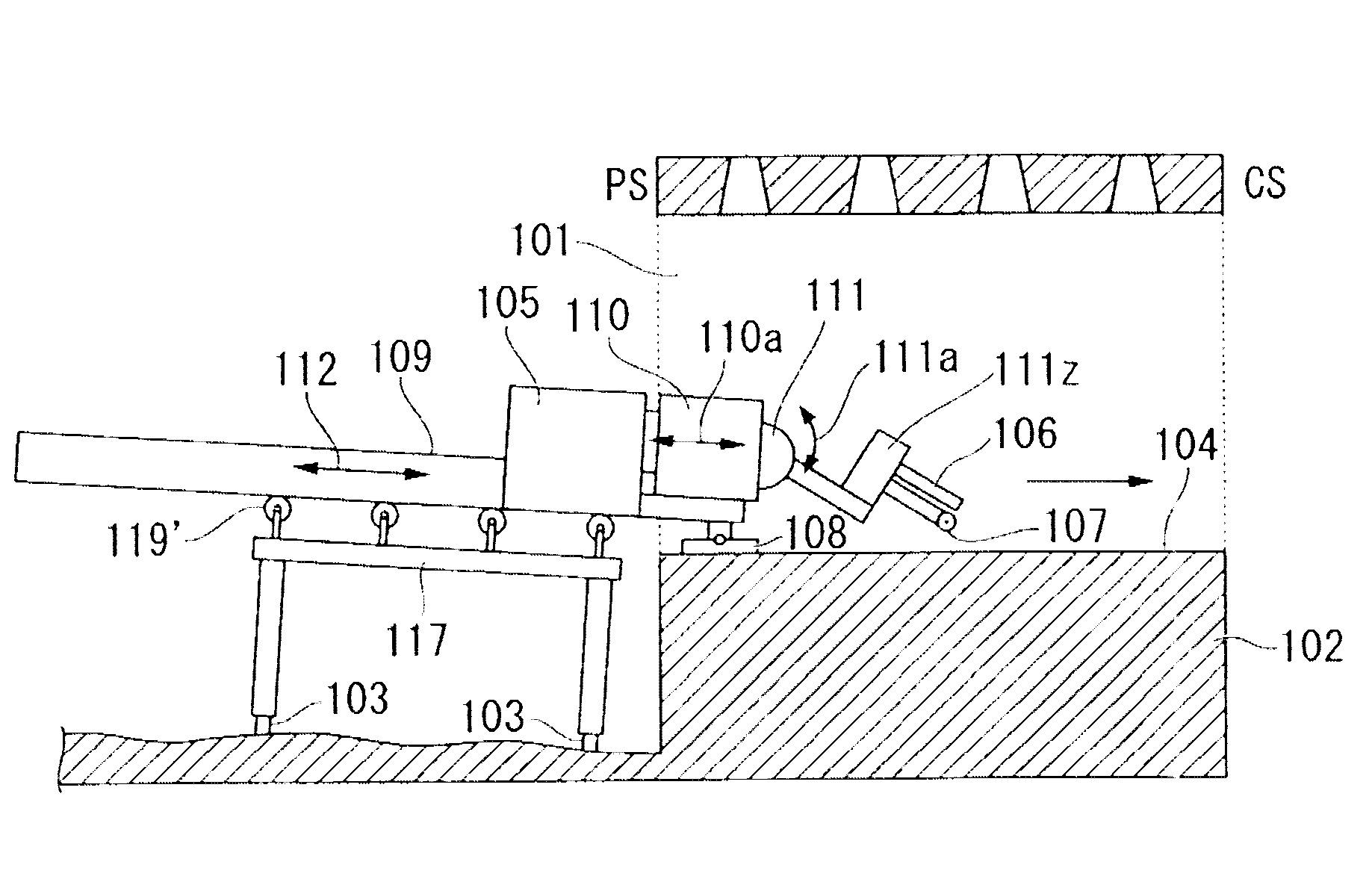

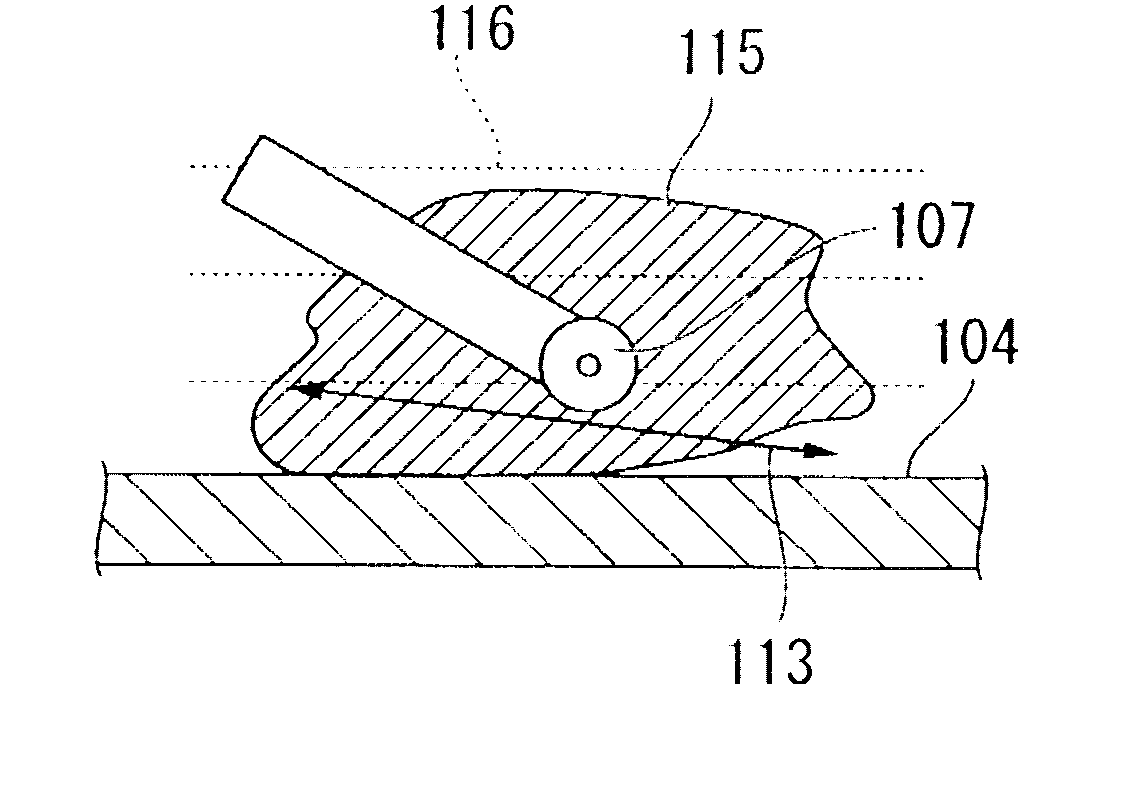

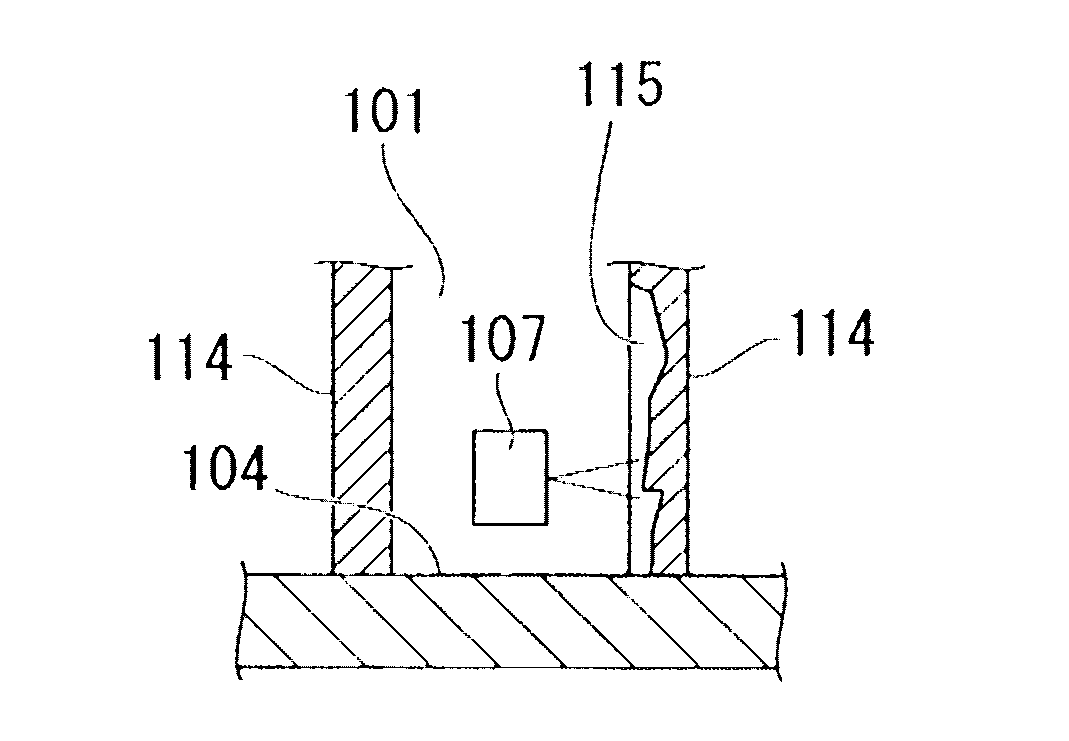

[0150] exist image 3 The figure shows the 1st embodiment which repairs the damaged part of a furnace bottom side wall surface using the repairing apparatus of this invention. The repair control device 5 is provided at the front end, and the elongated beam 9 capable of advancing and retreating along the furnace length direction 10 a is freely supported by elevating rollers 19 arranged on a trolley 17 on the rail 3 .

[0151] At the front end of the repair control device 5, a furnace length direction precision drive device 10 is connected to drive a furnace height direction precision drive device 11 along the furnace length direction 10a. The furnace height direction precision drive device 11 drives a furnace wall along the furnace height direction 11a. The shape measuring device 6 , the furnace bottom shape measuring device 18 , and the repair robot 11z of the spraying device 7 . The precision driving device 10 in the furnace length direction and the precision driving device ...

no. 2 Embodiment approach

[0171] exist Figure 11A ~ Figure 12 In FIG. 2 , the second embodiment of the present invention using two elongated devices mounted on one trolley 17 is shown.

[0172] The first elongated device includes: a first elongated beam 20 inserted into the carbonization chamber 1 of the coke oven; a furnace bottom shape measuring device 18 provided at the front end of the first elongated beam 20 via a first furnace longitudinal precision drive device 10 , by measuring the distance between the furnace bottom 4 and itself to obtain the concave-convex shape of the furnace bottom 4; the first furnace length direction precision driving device 10 adjusts the furnace length of the furnace bottom shape measuring device 18 in the coking oven carbonization chamber 1 The position in the direction; the first inclination angle sensor 22 measures the angle formed by the driving direction of the first furnace length precision driving device 10 and the horizontal direction.

[0173] On the other ha...

no. 3 Embodiment approach

[0185] exist Figure 13In , the state of posture control of the repairing device in the case where the leg of the repairing device of the present invention does not land on the furnace bottom is shown. Independently control the height position of the first lifting roller 26 that can be lifted and the height position of the second lifting roller 27 that can be lifted and lowered independently, and carry out the positioning of the repair control device 5, so that the scanning direction of the furnace length direction precision drive device 10 is in line with the The approximate curves of the bottom of the furnace are parallel. At this time, positioning is performed so that the center of gravity 28 of the repairing device is located between the first elevating driving roller 26 and the second elevating driving roller 27 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com