Ni-based heat-resistant alloy

A heat-resistant alloy and quality technology, applied in the field of Ni-based heat-resistant alloys, can solve the problems of insufficient creep rupture strength of Fe-based alloys, and achieve the improvement of zero ductility temperature and hot workability, ductility and toughness improvement, high intensifying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

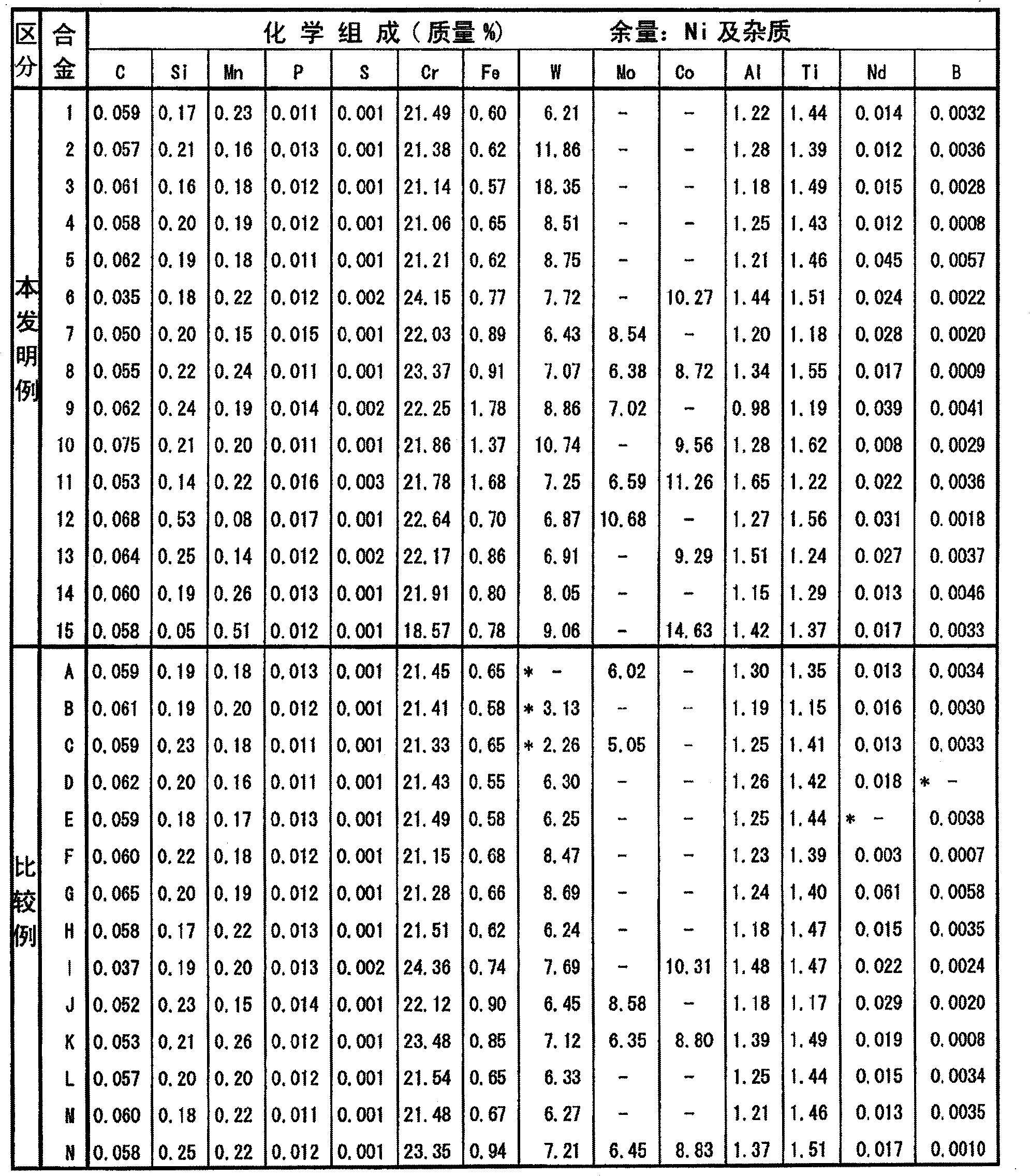

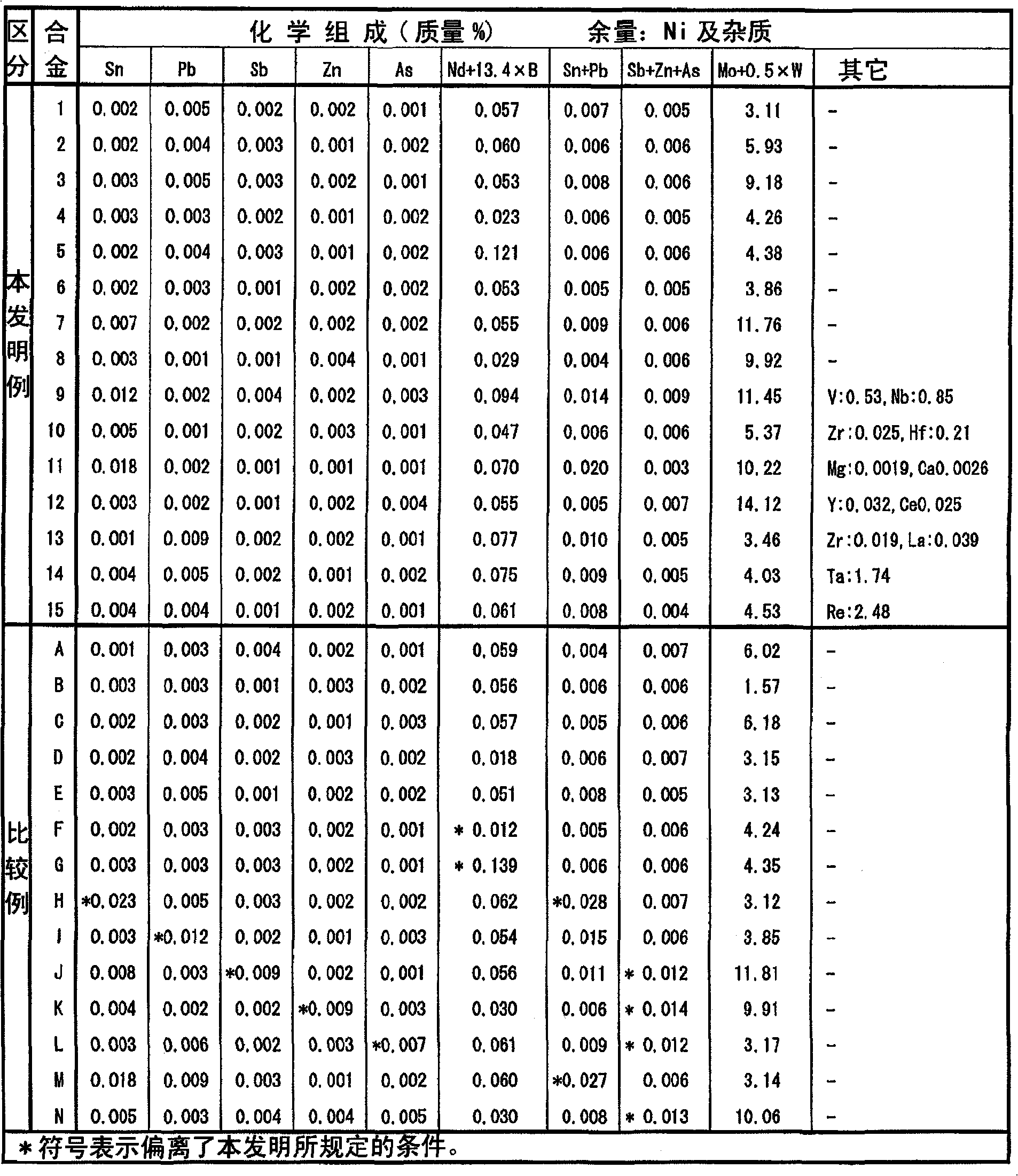

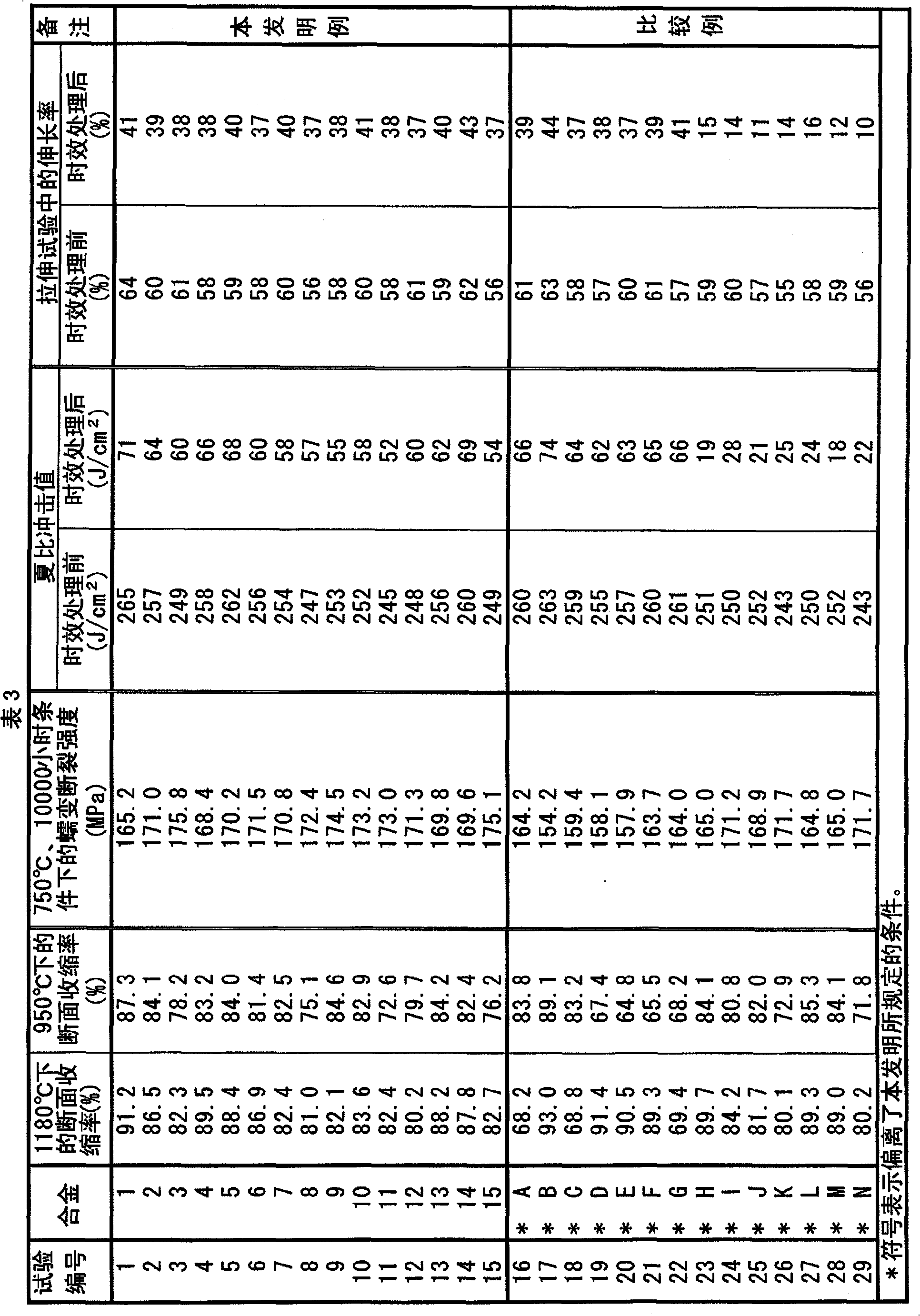

[0169] Austenitic alloys 1 to 15 and A to N having the chemical compositions shown in Table 1 and Table 2 were melted using a high-frequency vacuum melting furnace to obtain 30 kg ingots.

[0170] Alloys 1 to 15 in Table 1 and Table 2 are alloys whose chemical compositions are within the range specified by the present invention. On the other hand, alloys A to N are alloys of comparative examples whose chemical compositions deviate from the conditions specified in the present invention. In addition, both alloy F and alloy G are alloys in which the respective contents of Nd and B are within the ranges specified in the present invention, but the value of [Nd+13.4×B] does not satisfy the aforementioned formula (1). In addition, the alloy M is an alloy in which the respective contents of Sn and Pb are within the ranges specified in the present invention, but the value of [Sn+Pb] does not satisfy the aforementioned formula (2). Alloy N is an alloy in which the respective contents o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com