Method for determining shape parameters

A shape parameter and elongated technology, applied in the direction of optical devices, instruments, metal rolling, etc., can solve the problems of uncertain center of circle, unable to reflect the profile characteristics, etc., and achieve the effect of eliminating deviation value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

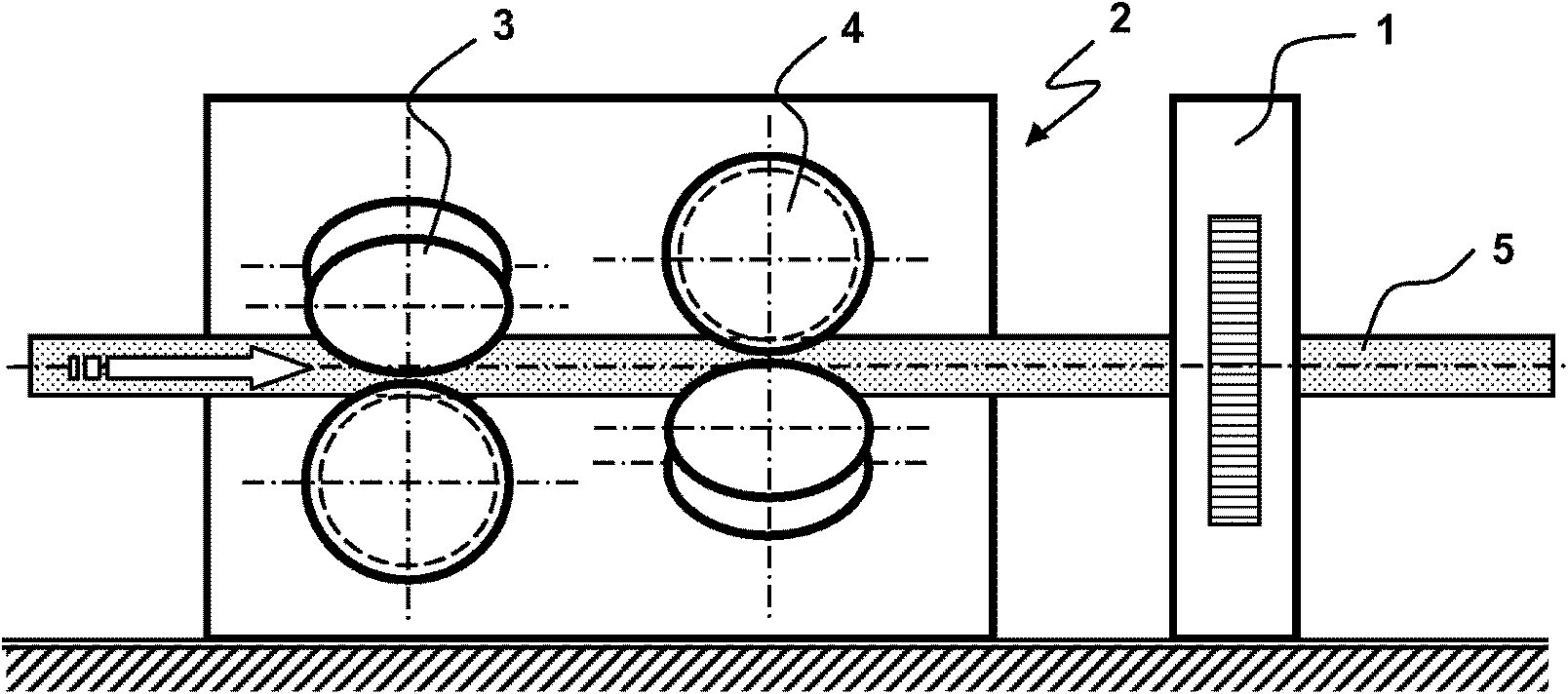

[0075] figure 1 The last two stages of a three-roll stand with measuring device 1 described below are shown very simplified in . Each stage has three rollers 3 , 4 , thus a three-roll roller set, of which only two of the three rollers are each shown for reasons of better clarity. Here, the penultimate three-roll roll set 6 is shown on the left, and the last three-roll roll set 7 is shown on the right. The rolling stand is used for rounding elongated products and thus for producing round profiles 5 . Arrows indicate rolling direction.

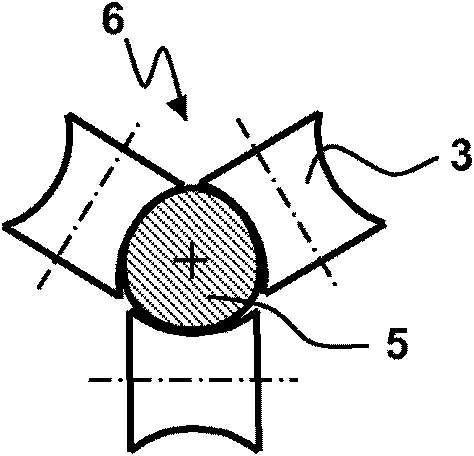

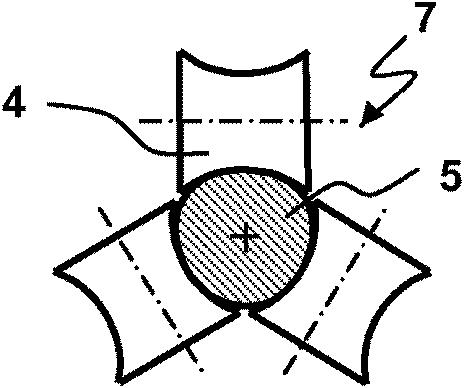

[0076] figure 2 and image 3 The arrangement of the penultimate three-roller set 6 and the last three-roller set 7 viewed from the measuring device 1 is shown.

[0077] Figure 4 The measured values important for rolling round products with a three-high stand are shown in . In this case, the measured values include in particular the diameter DT measured at the three pressure points of the last three-roll set 7 (shaded arrows) as well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com