Alkali metal vacuum injecting device

A filling device, alkali metal technology, applied in the direction of feeding device, chemical instrument and method, chemical/physical process, etc., can solve the problems of scrapping the whole part of the device, high requirement of working medium purity, high vacuum, etc., to achieve guaranteed normal working effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

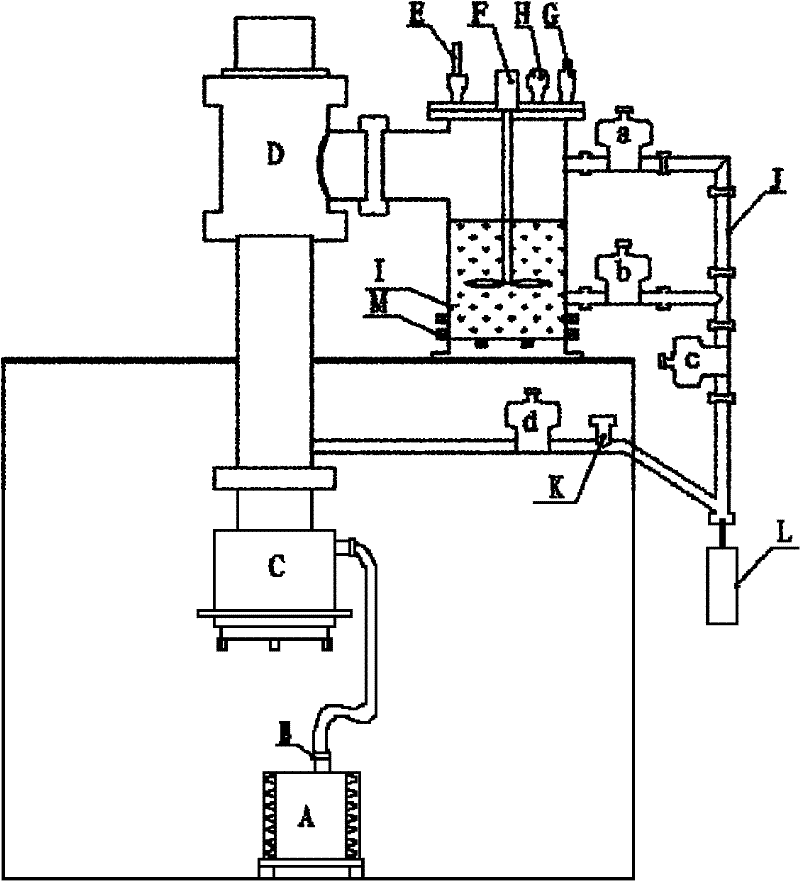

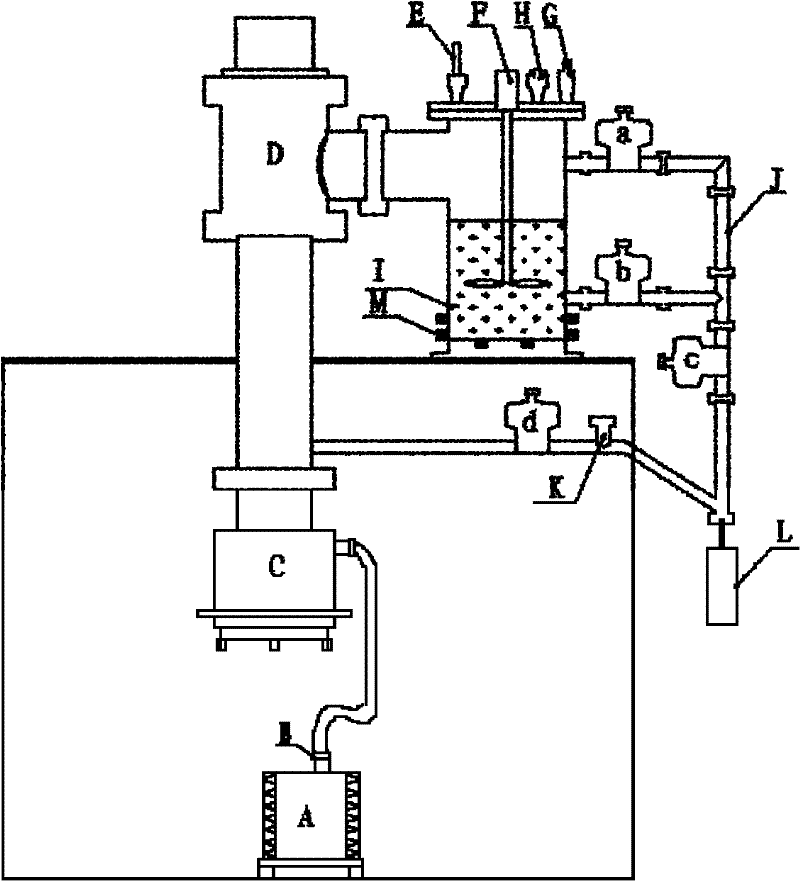

[0015] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0016] to combine figure 1 , the present invention includes a mechanical pump A, a solenoid valve B, a molecular pump C, an inflation valve D, a thermocouple interface E, a manual stirrer F, an inflation port G, a vacuum gauge H, a storage tank I, a measuring section J, and an ultra-high vacuum Ionization gauge K, test device L and heater M, valves a~d. The mechanical pump A is connected to the molecular pump C, the molecular pump C is equipped with a cylinder, the charging valve D is installed on the cylinder, the storage tank I is connected to the cylinder, the heater M is installed on the storage tank I, and the test device L is connected to the cylinder through a tube , The test device L is also connected to the storage tank I through the measuring section J. Solenoid valve B is installed between mechanical pump A and molecular pump C. A thermocouple interf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com