Multichannel parallel pipe type reactor system

A tubular reactor and multi-channel technology, applied in the field of reactor systems, can solve the problems of high cost, speed up the development of new materials, and large volume, and achieve the effect of low design cost, simple and novel constant temperature section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

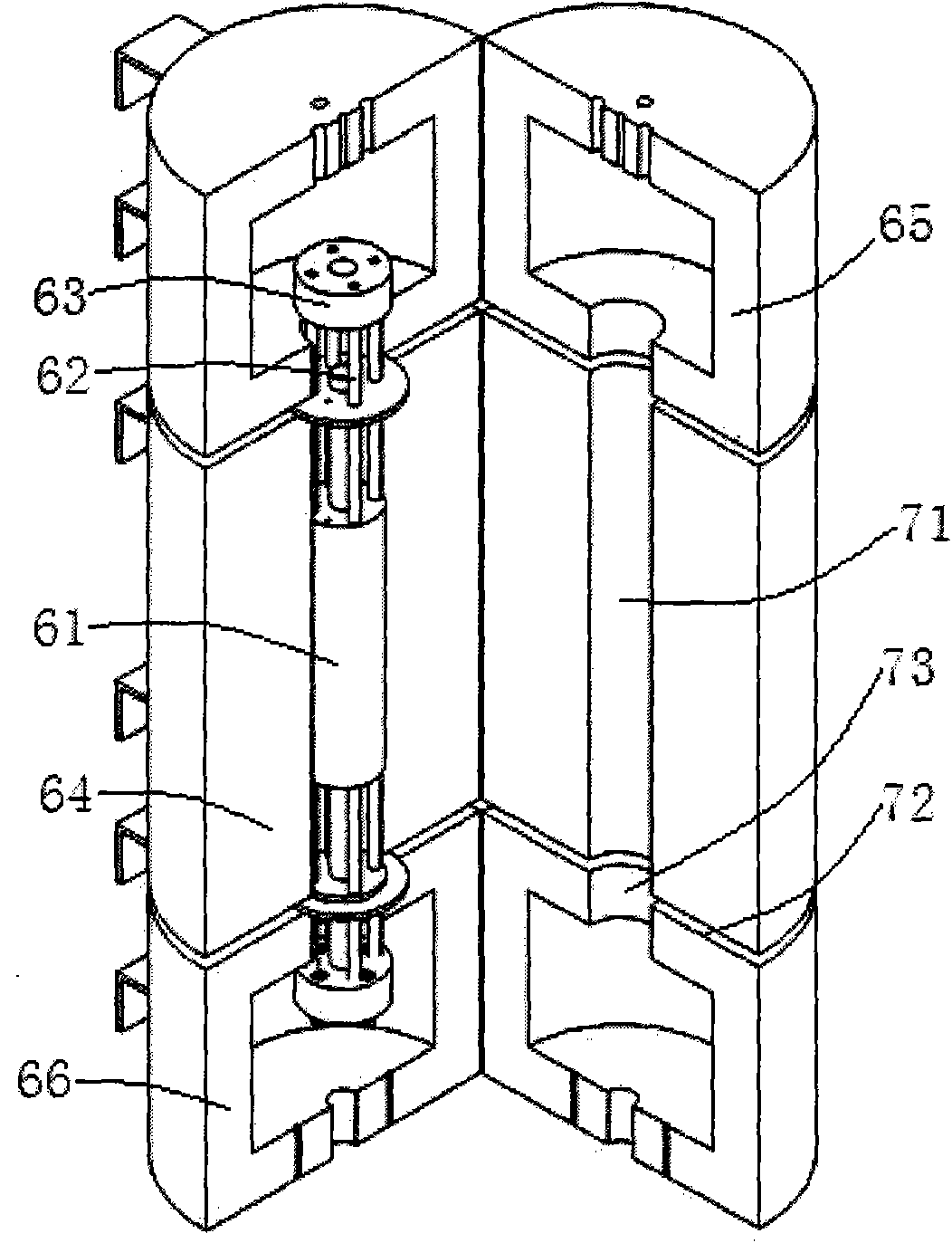

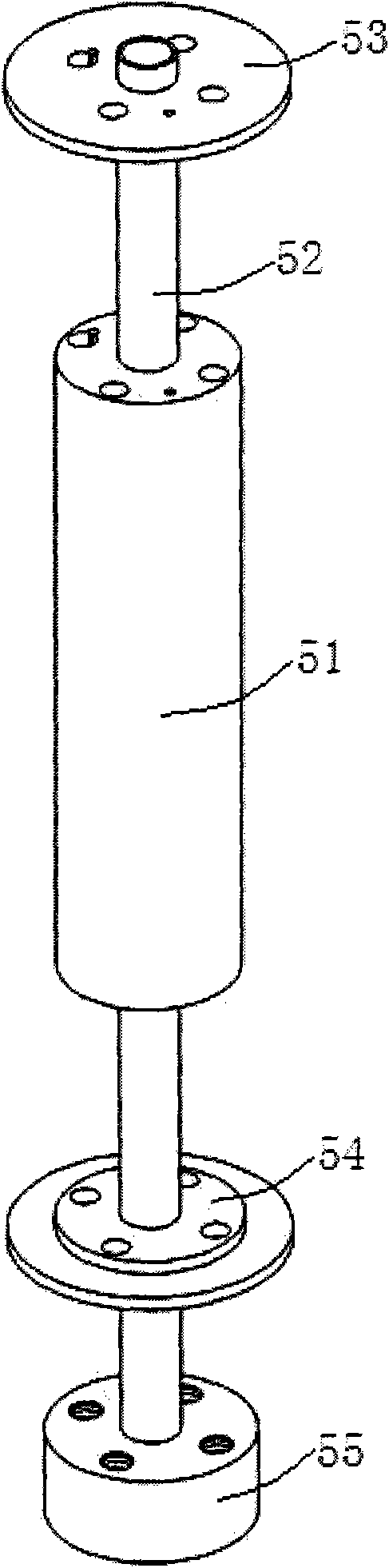

[0024] see figure 1 with figure 2 , The multi-channel parallel tubular reactor system of the present invention includes a reactor 61 , a heating furnace 64 and heat preservation covers 65 and 66 . Wherein, the reactor 61 includes a copper bath 51 , a support tube 52 , end caps 53 and 54 , multi-way joints 55 and 63 and a reaction tube 62 .

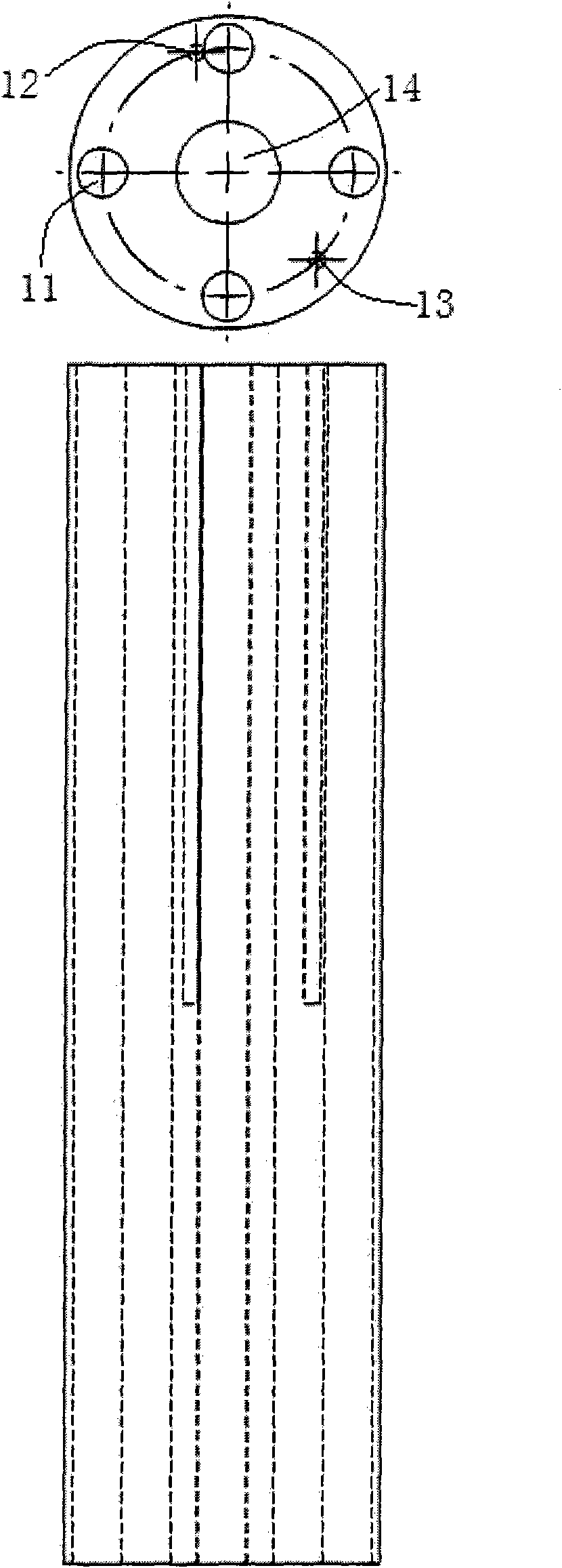

[0025] see figure 2 with image 3 , the center of the copper bath 51 offers a larger support tube hole 14, the size of the support tube hole 14 is adapted to the diameter of the support tube 52 for its insertion, such a design can reduce the weight of the copper bath 51, but also To the role of fixing the copper bath 51. The copper bath 51 also defines four reaction tube holes 11 around the support tube hole 14, and the reaction tube holes 11 are evenly distributed on a circle with a suitable diameter. The upper end of the copper bath 51 also offers a temperature measuring hole 12 and a temperature control hole 13, which are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com