Method for forming notch on pipe and stamping die thereof

A technology for stamping dies and pipes, which is applied to a method for opening gaps in pipes and the field of stamping dies, which can solve problems such as uneven gaps, easy deformation and fracture of pipes, and achieve improved flatness, uniform force, and avoid deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

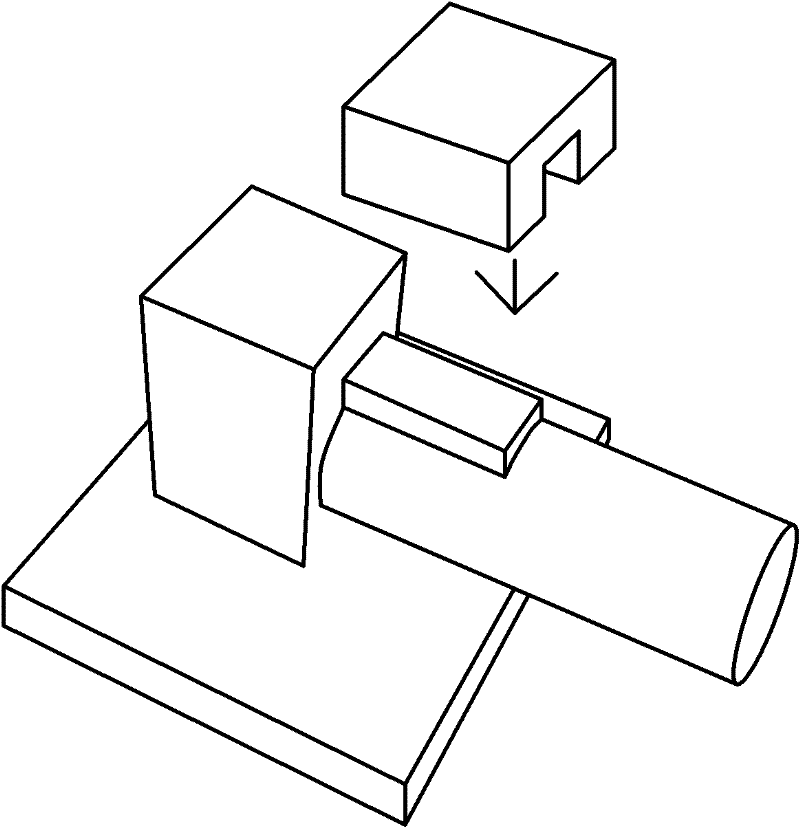

[0018] Example. A method for opening a gap in a pipe, characterized in that: the pipe is placed on the punch, punched down to a supporting block with a blanking hole that is the same size as the required gap, and the punch squeezes into the blanking hole to form Guillotine cut to create a notch in the tubing. The support block is provided with an arc-shaped groove, the shape of which is consistent with the pipe to be processed, and the blanking hole is arranged in the arc-shaped groove, and three cutting edges in the shape of a door are formed on the arc-shaped groove. The upper end of the punch is arc-shaped, and the shape is consistent with the pipe to be processed.

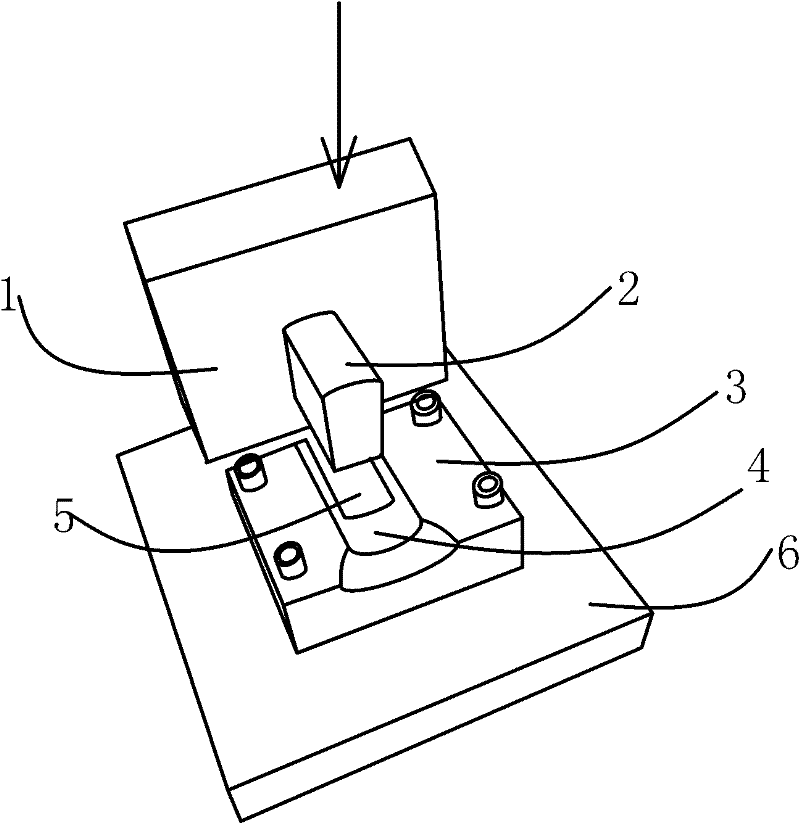

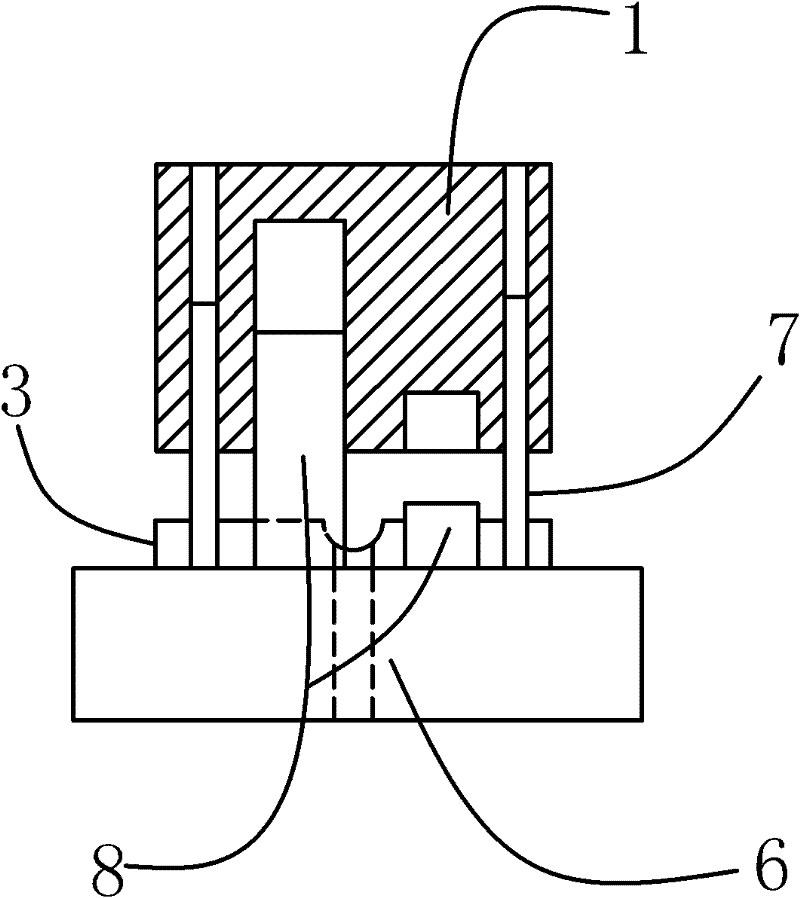

[0019] A stamping die for opening gaps in pipes, such as Figure 2 ~ Figure 3 As shown, it includes a punch 2 and a support bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com