Cutter damage adaptive alarm method based on wavelet packet and probability neural network

A probabilistic neural network and self-adaptive technology, which is applied in the field of self-adaptive alarming of tool damage based on wavelet packet analysis and probabilistic neural network modeling, can solve the problems of prone to missed and false positives, achieve real-time detection of tool status, improve The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

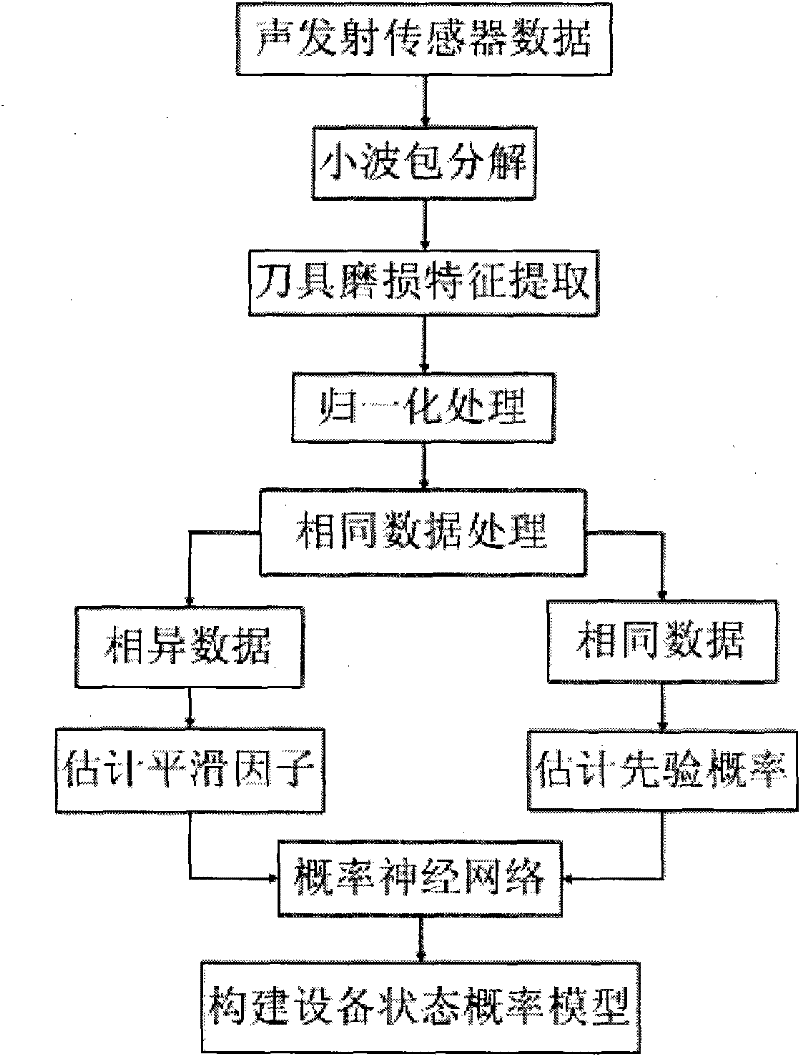

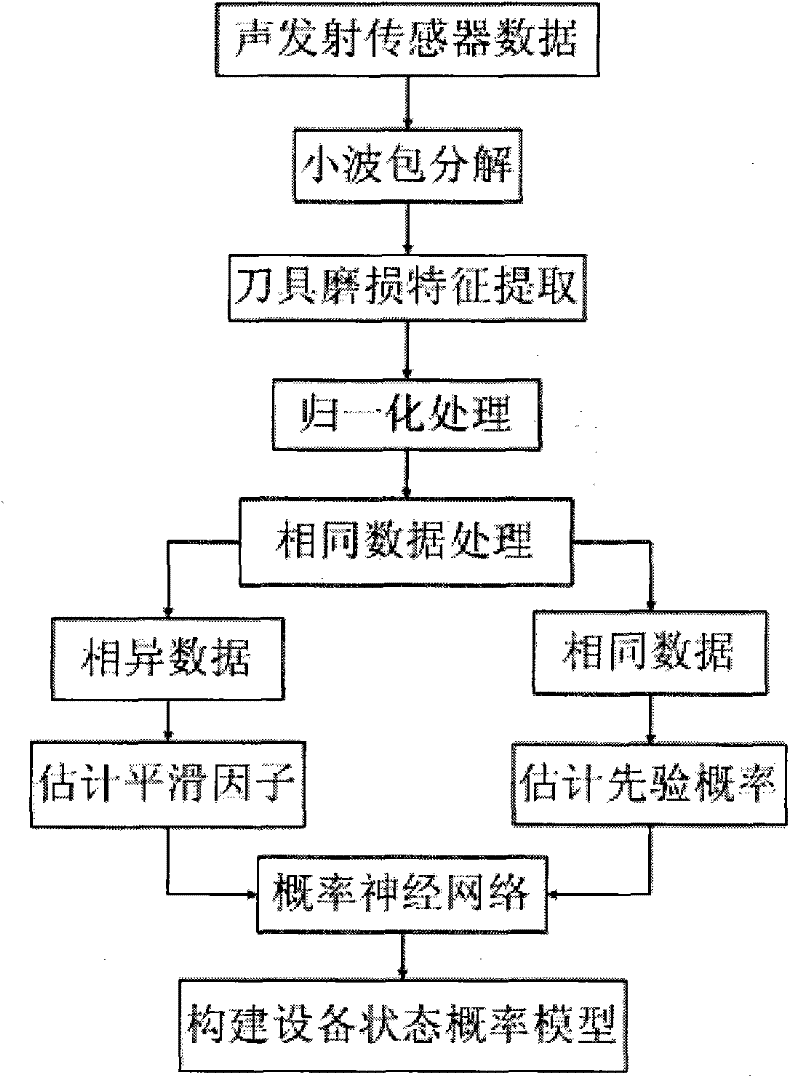

[0015] With reference to accompanying drawing, based on wavelet packet and probabilistic neural network tool breakage self-adaptive warning method, comprises the following steps:

[0016] The first step is to polish the part of the tool bar where the acoustic emission sensor is fixed, apply butter, and then fix the acoustic emission sensor to the tool bar, and use the acoustic emission signal data acquisition program based on Labview to collect the acoustic emission signal through the PCI card;

[0017] In the second step, the collected acoustic emission signals are analyzed by three-layer wavelet packets, and each group of signals is decomposed into eight frequency bands, namely 0~124khz, 125~249khz, 250~499khz, 500~549khz, 550~599khz, 600~649khz, 650~699khz, 700~749khz, among them, 125~249khz and 250~499khz are the two frequency bands with the largest energ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com