Soft and hard combined plate structure capable of avoiding fracture of soft plate

A soft-rigid combination board and soft board technology, applied in the direction of layered products, etc., can solve the problems of disconnection, machine failure, and the soft board 4 is easily squeezed, so as to ensure the service life and avoid excessive stress concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

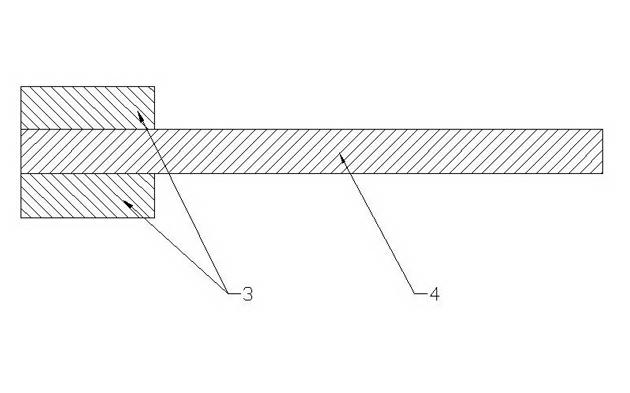

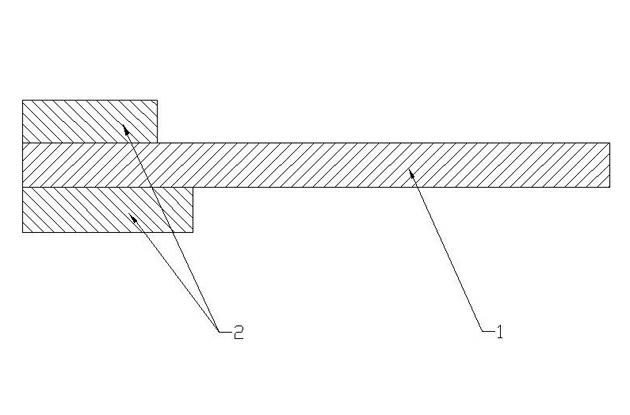

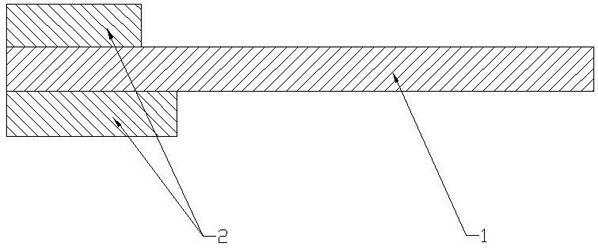

[0009] Such as figure 2 As shown, the present invention includes a soft board 1 arranged on the inner side, a hard board 2 arranged on both sides of the soft board 1, and the hard board 2 on the front and back sides of the soft board 1 is connected with the soft board 1. Fit height varies. According to requirements, the setting ratio of the lamination height difference between the front and back sides of the soft board 1 of the hard board 2 is less than 0.5 mm.

[0010] In the present invention, the bonding heights of the rigid boards 2 on both sides of the soft board 1 and the soft board 1 are set differently, and the difference in the bonding height is used to make the soft and hard boards fit together more smoothly. The soft-hard transition areas on the front and back of the flexible board 1 are staggered to avoid stress concentration on the flexible board 1 and cause disconnection of the flexible board 1 , thereby ensuring product quality and product life.

[0011] To s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com