Multi-layer staggered split type high-pressure device

A high-pressure device and split-type technology, which is applied in the field of multi-layer staggered split-type high-voltage devices, can solve the problems of stress concentration on the split surface, limited preload force, large preload force, etc., so as to improve the sintering quality and stress Uniform and reasonable, the effect of increasing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The multi-layer staggered split high-voltage device involved in the present invention will be further described below with reference to the accompanying drawings.

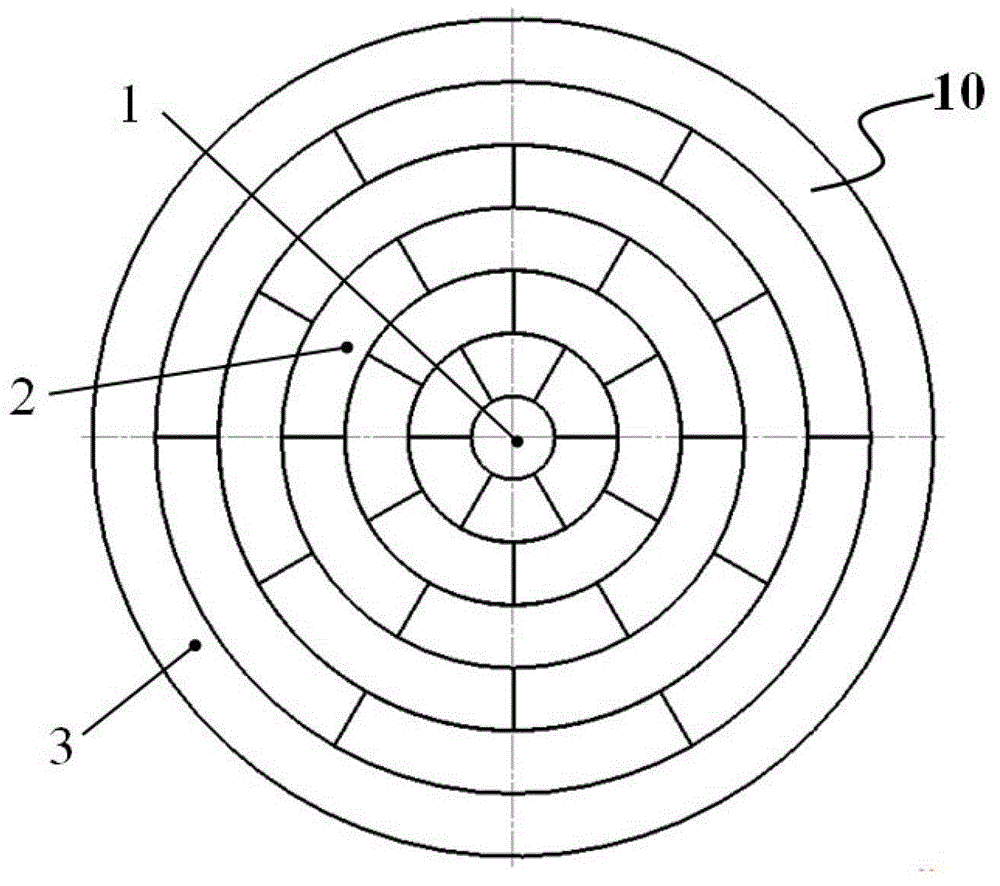

[0045] figure 1 It is a schematic diagram of a multilayer staggered split type high-voltage device 10 according to an embodiment of the present invention.

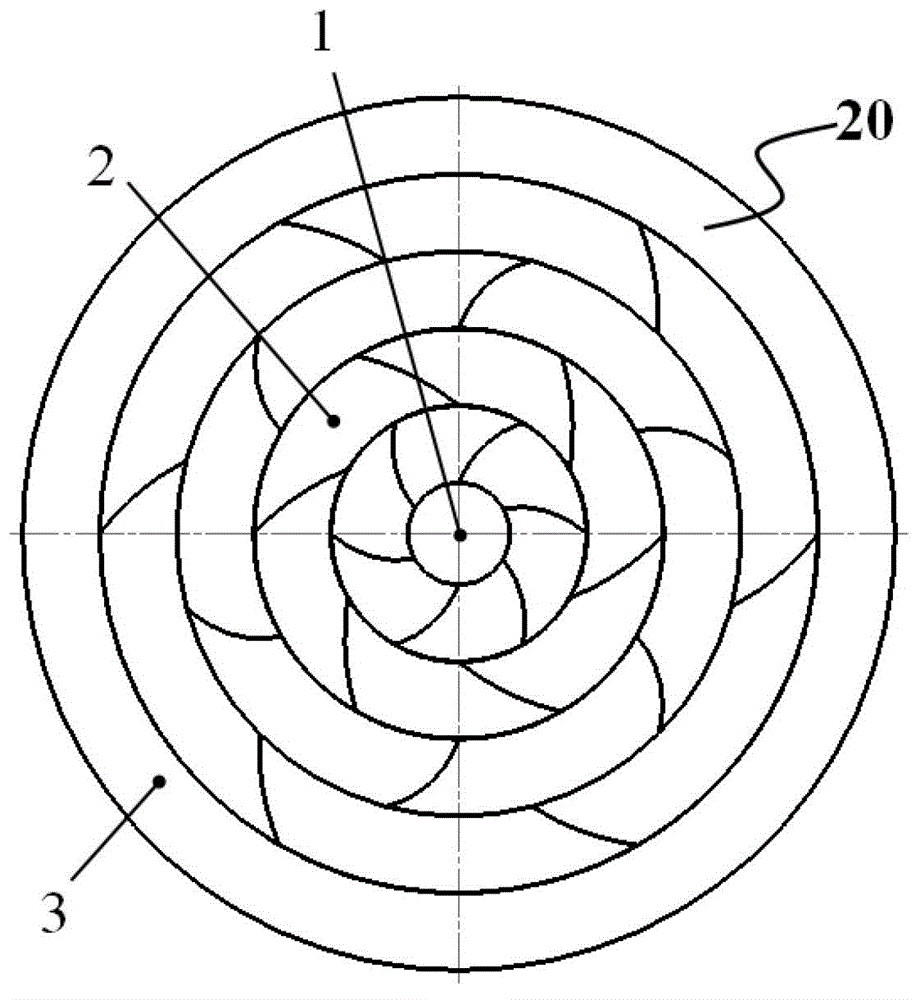

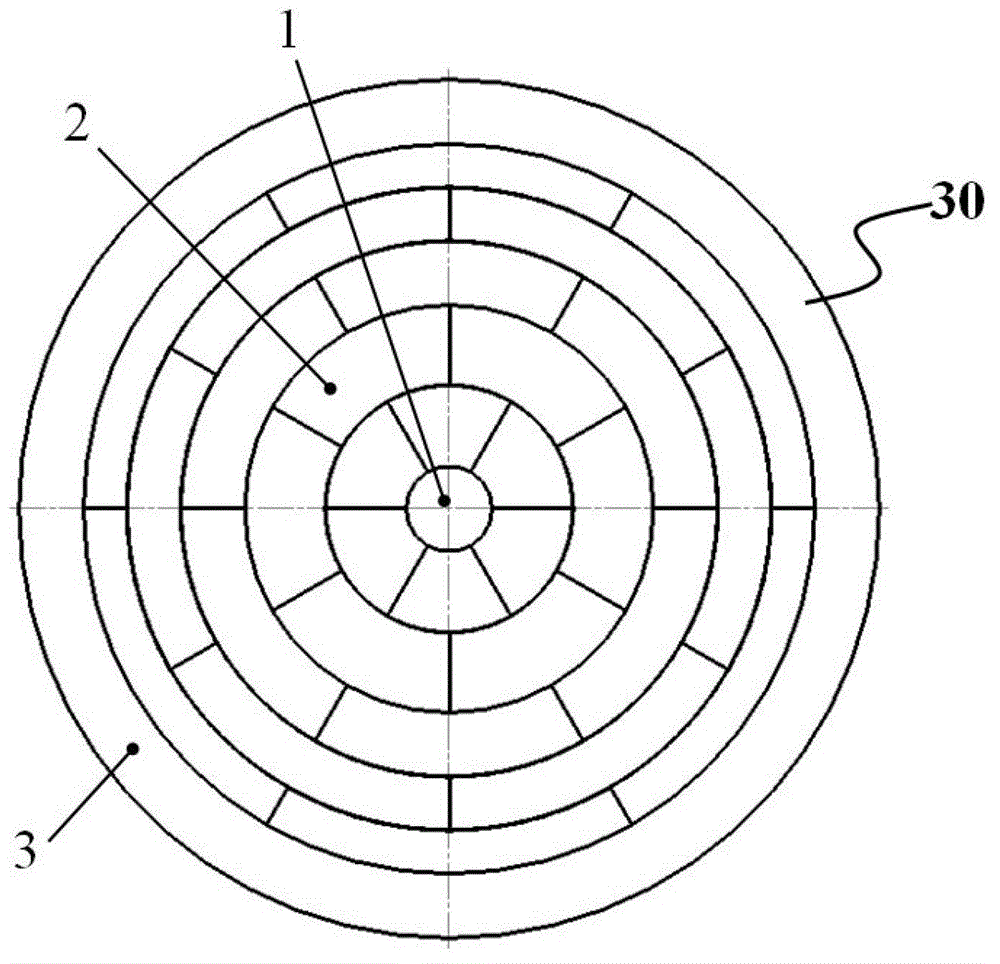

[0046] The multi-layer staggered split type high-voltage device 10 includes a split block 2, a fixed ring 3, a pressure head, a hydraulic cylinder, a frame, etc. (not shown), and the split block 2 is divided into 5 layers (not limited to 5 layers), And the subdivision blocks 2 of each layer are staggeredly combined, and the cavity 1 is surrounded by the subdivision blocks 2; In the fixed ring 3, the split block 2 is closely matched with the fixed ring 3; in the multi-layer staggered split type high-voltage device 10, the two ends of the internal split block 2 assembly can be tapered surfaces (refer to Figure 7 ), utilize the large-mass support princip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com