Self-standing steel chimney

A self-supporting chimney technology, applied in the field of chimneys, can solve problems such as difficult installation methods, deformation of the inner cylinder, and stress concentration at the joint of the inner and outer cylinders, and achieve the effects of reducing safety hazards, prolonging service life, and simplifying installation operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment:

[0029] This example includes:

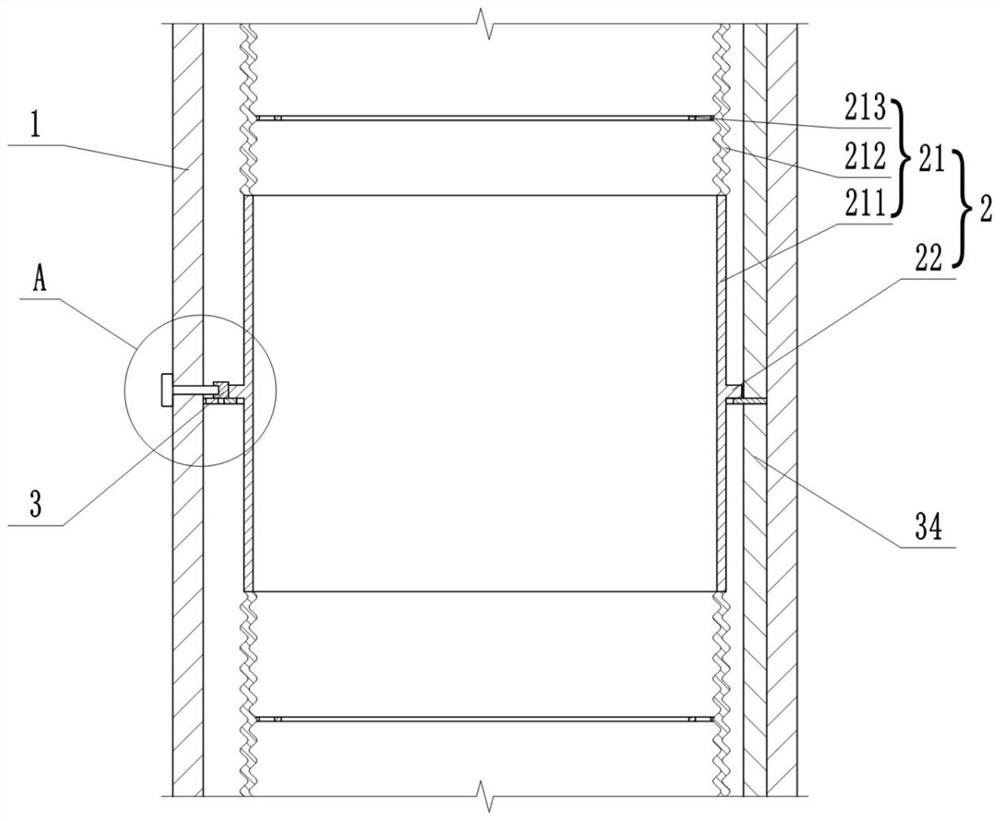

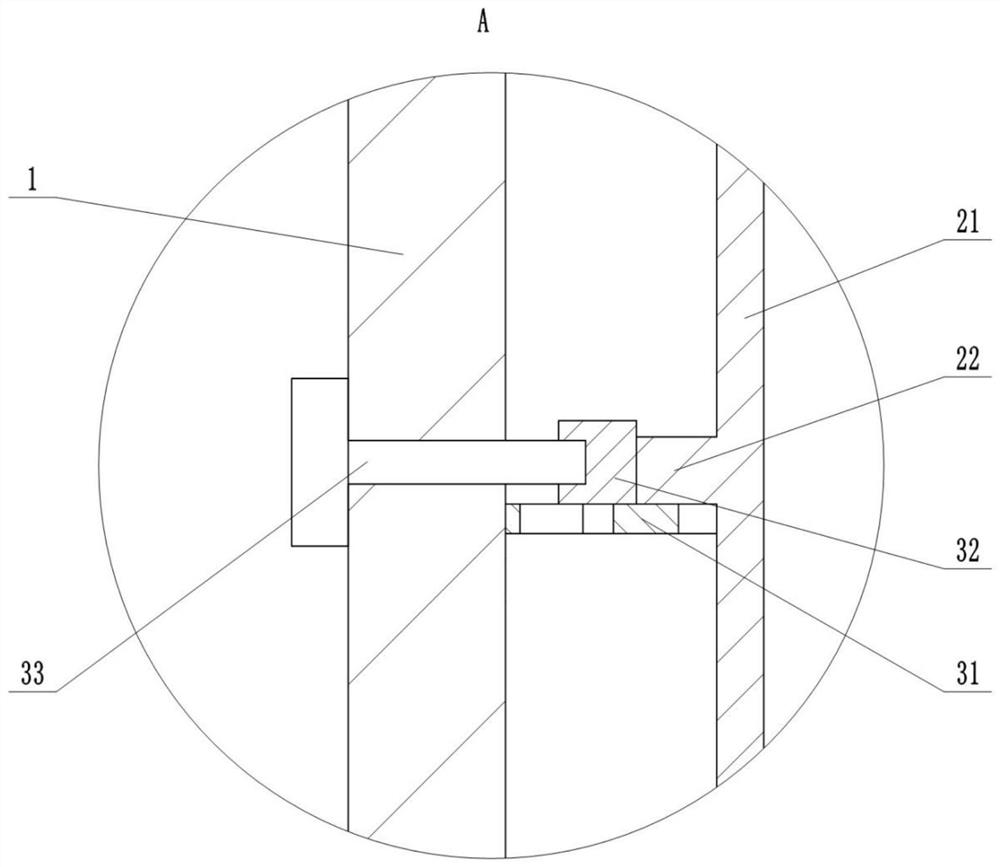

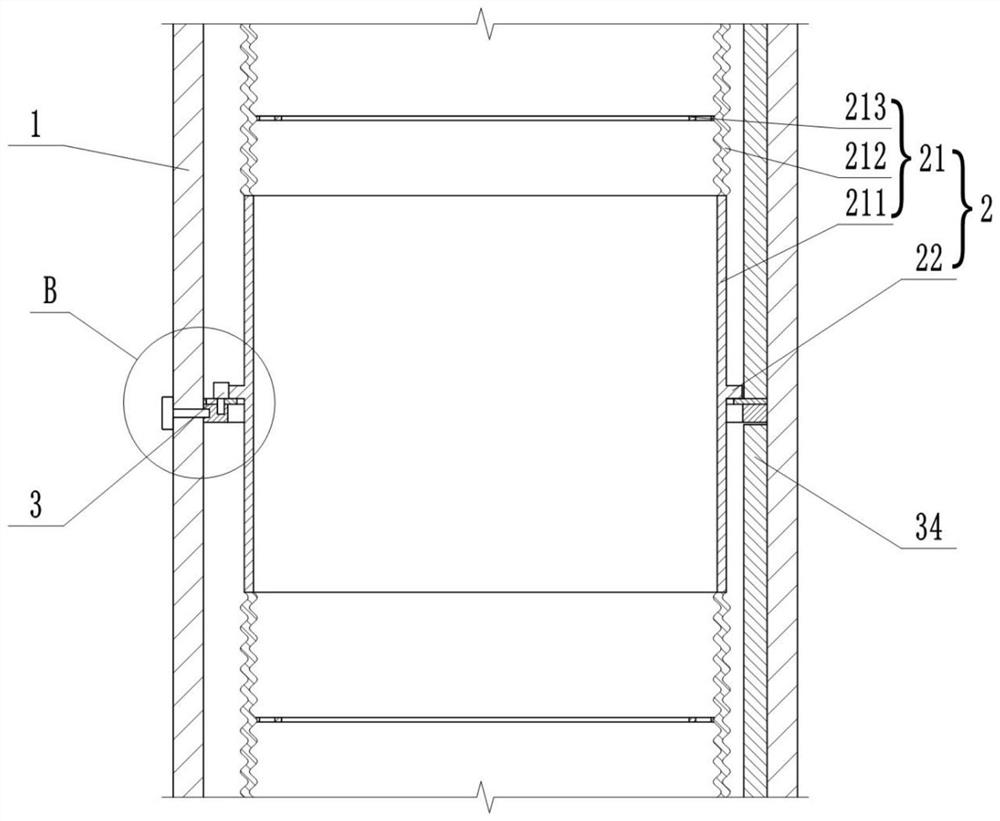

[0030] The outer cylinder 1 and the inner cylinder 2, the inner cylinder 2 is located inside the outer cylinder 1, the inner cylinder 2 includes a plurality of telescopic cylinder units 21, the telescopic cylinder units 21 can adopt an elastic structure with variable length, the structure includes a hard section 211 and a length Adjustable soft section 212, the support ring 22 is located on the hard section 211, the soft section 212 can be a bellows or rubber tube, or other soft materials that can be stretched in the axial direction, the inner wall of the soft section 212 A receiving ring 213 for receiving the impact force of the airflow is fixed on the top;

[0031] The connection structure 3, the connection structure 3 includes a plurality of retaining rings 31 corresponding to the telescopic cylinder unit, the retaining rings 31 are arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com