Five-axle linkage control three-dimensional printing device

A five-axis linkage, three-dimensional printing technology, applied in printing devices, printing, typewriters, etc., can solve the problems affecting the efficiency and quality of mass production of products, and no three-dimensional printer products have been seen, and achieve the effect of improving printing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

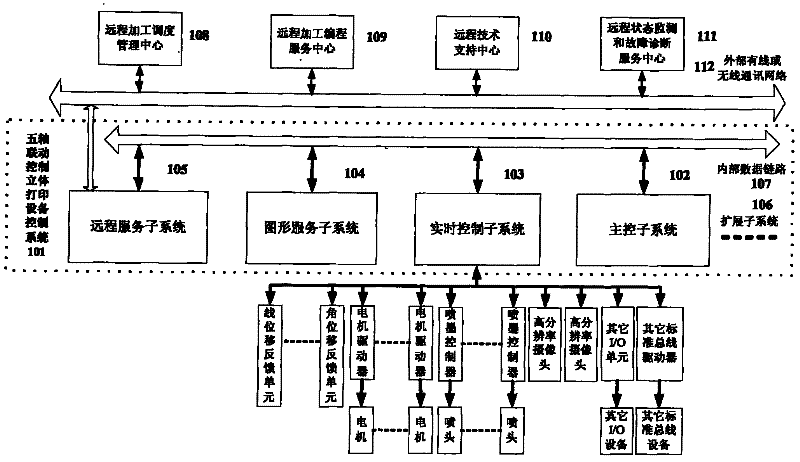

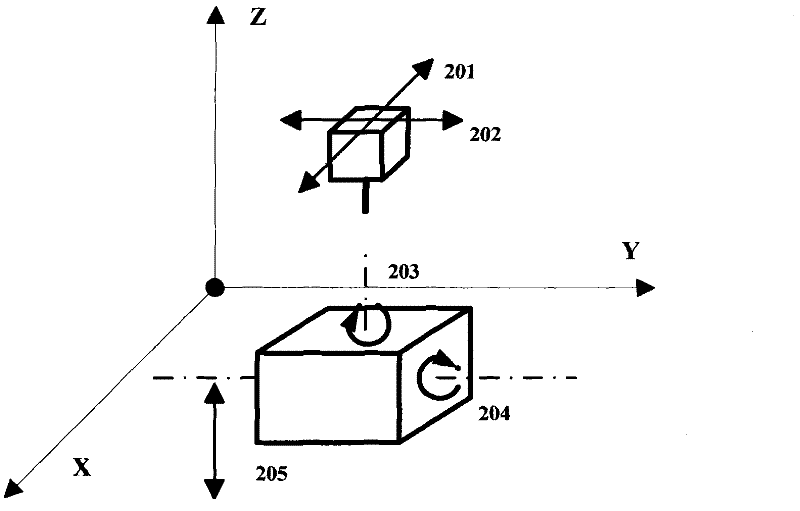

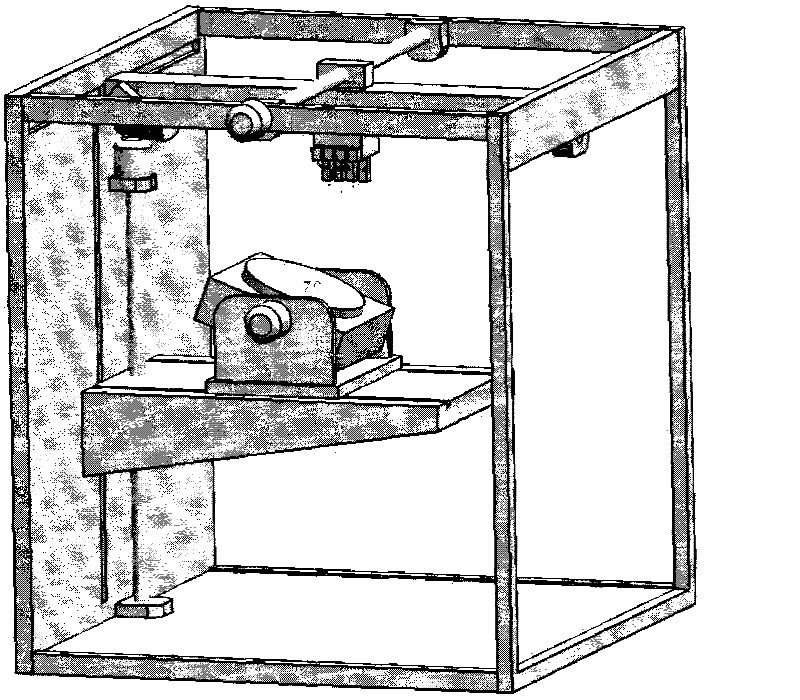

[0035] Five-axis linkage control three-dimensional printing equipment is divided into control system, mechanical motion structure, printing system and calibration system, which are introduced separately below.

[0036] 1. Control system

[0037] Five-axis linkage control The control system part of the three-dimensional printing equipment is the core of the whole equipment. With the above-mentioned five-axis linkage mechanical structure and special printing system structure, the control system part needs to closely combine the five-axis linkage motion control and printing control. At the same time, make full use of the advantages of the software to realize the functions from three-dimensional color modeling to entity motion trajectory planning and three-dimensional color positioning analysis, so as to realize the complete three-dimensional printing function. Therefore, the control system part must not only meet the needs of various real-time motion control and synchronous print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com