Full-automatic laser marking system

A laser laser and laser marking technology, applied in printing devices, printing, etc., can solve problems such as rough borders and slow speeds, and achieve the effects of high drawing efficiency, fast response speed, and high graphics accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

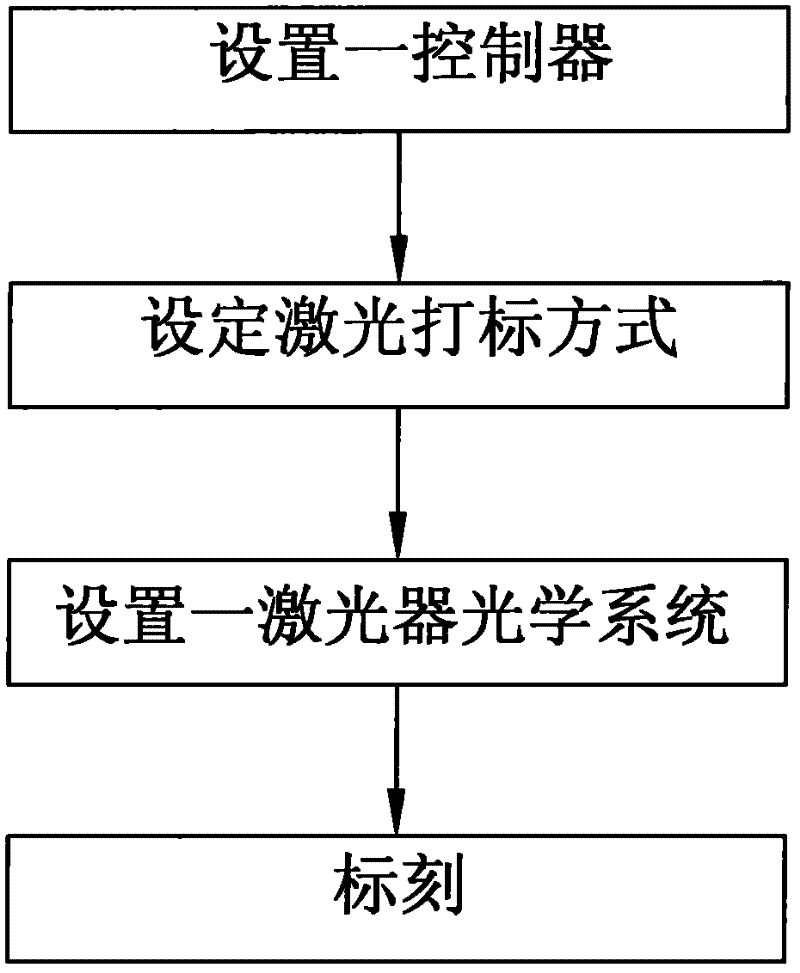

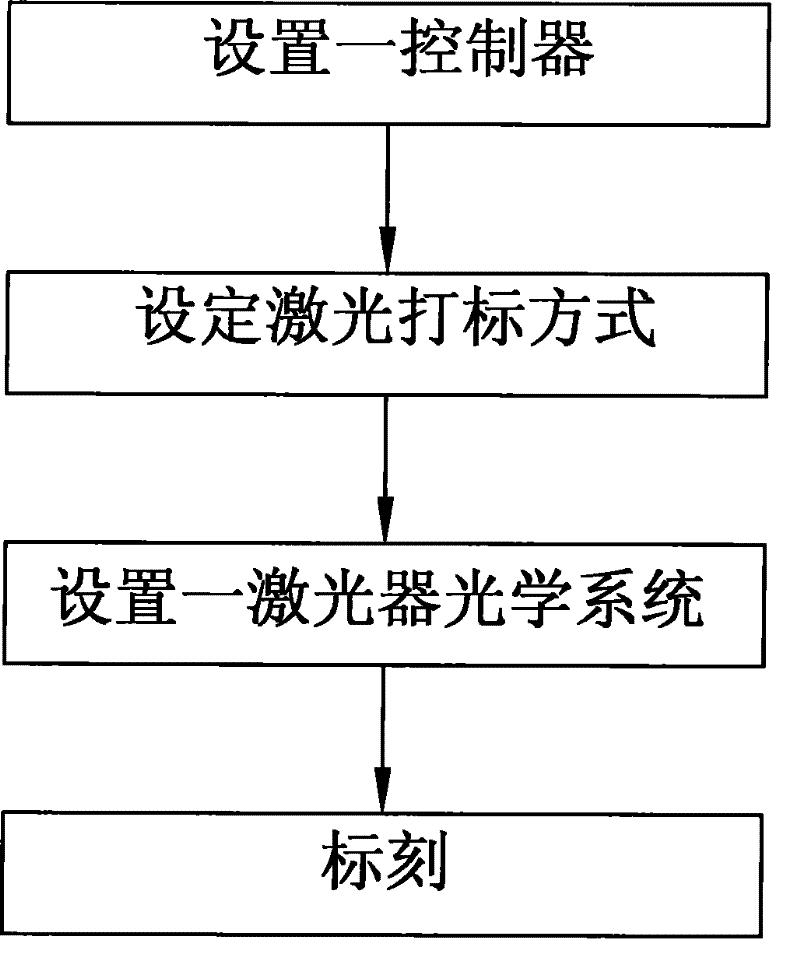

[0019] see figure 1 , a fully automatic laser marking system provided in this embodiment, which includes

[0020] (1) A controller is set to control the galvanometer system;

[0021] (2) Set the laser marking method, connect the peripheral device control interface according to the requirements, and uniformly identify and collect different file formats through digital cameras or scanners;

[0022] (3) Set up a laser optical system, which can recognize and collect any complex plane images, graphic characters, two-dimensional codes and bar codes made in the computer through the input of digital cameras or scanners, convert them into digital signals, and calculate through programming Convert it into a current control signal and input it to the driver to form a corresponding control signal and control the high-precision servo motor to control the deflection angle of the reflective galvanometer in the x direction and y direction respectively, so that the focused spot of the laser b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com