Device and process for processing high-salt non-biodegradable toxic industrial waste water

A technology for refractory biodegradable industrial wastewater, applied in the field of industrial wastewater treatment devices, can solve the problems of not being able to effectively improve the biodegradability of wastewater, and achieve the effects of avoiding excessive water quality, low operating costs, and good treatment effects

Active Publication Date: 2011-09-07

浙江环科环境研究院有限公司

View PDF5 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, only iron-carbon micro-electrolysis, electrocatalytic oxidation or

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

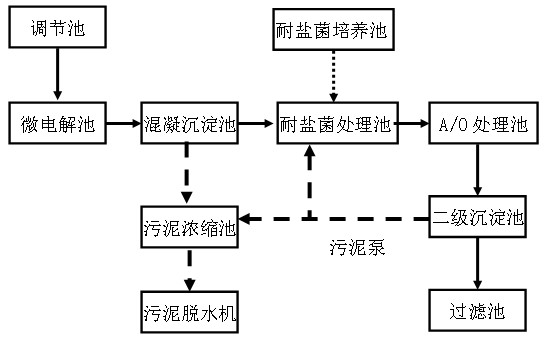

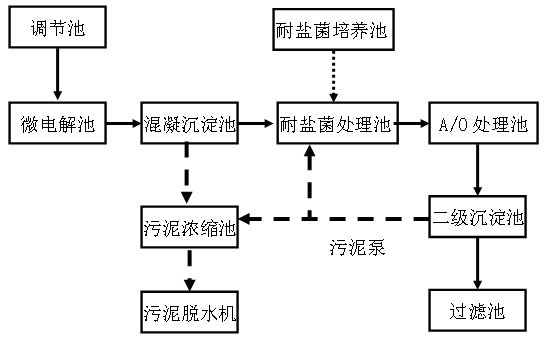

The invention discloses a device and process for processing high-salt non-biodegradable toxic industrial waste water. An A/O processing pool comprises an A section and an O section; a regulation tank, a micro-electrolytic tank, a coagulation sedimentation tank, a halotolerant bacteria processing tank, an A/O processing tank, a secondary sedimentation tank, a filtering tank are sequentially connected; a sludge concentration tank is connected with the coagulation sedimentation tank, the secondary sedimentation tank and a sludge dewatering machine; and a halotolerant bacteria culture tank is connected with the halotolerant bacteria processing tank. The high-salt non-biodegradable toxic industrial waste water enters the regulation tank for regulation of water quality and quantity, and most of the non-biodegradable organisms and toxic substances are removed through the micro-electrolytic tank and coagulation sedimentation tank; the supernate of the coagulation sedimentation tank enters the halotolerant bacteria processing tank which can improve the halotolerancy of biochemical sludge; the output water of the halotolerant bacteria processing tank is subjected to biochemical processing of the A/O processing tank, and the sludge is separated by the secondary sedimentation tank; and the supernate is filtered by the filtering tank, and the output water meets the standard and is discharged. The device and process disclosed by the invention have a good processing effect and low operation cost.

Description

technical field [0001] The invention relates to the field of environmental protection, in particular to a treatment device and process for treating high-salt, difficult-to-biodegrade and toxic industrial wastewater. Background technique [0002] Industrial wastewater such as medicine, chemical industry, printing and dyeing dyes often contains difficult biodegradable and toxic components, so it is not feasible to directly use biochemical methods. The current pretreatment methods before biochemistry include iron-carbon micro-electrolysis, electrocatalytic oxidation or Fenton oxidation, but Iron-carbon micro-electrolysis is easy to agglomerate, and the operating cost of electrocatalytic oxidation or Fenton oxidation is high. Therefore, how to strengthen the pretreatment before biochemistry is very important. At the same time, organic wastewater with high salinity is also produced in the process of industrial production, and the salt concentration of comprehensive wastewater oft...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F9/14C02F11/12C02F1/461

Inventor 韦彦斐仝武刚李欲如梅荣武沈浙萍

Owner 浙江环科环境研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com