Method for preparing corn peptide

A technology of corn peptide and corn gluten powder, which is applied in the field of preparation of plant protein composition, can solve the problems of ineffective production of corn peptide and achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

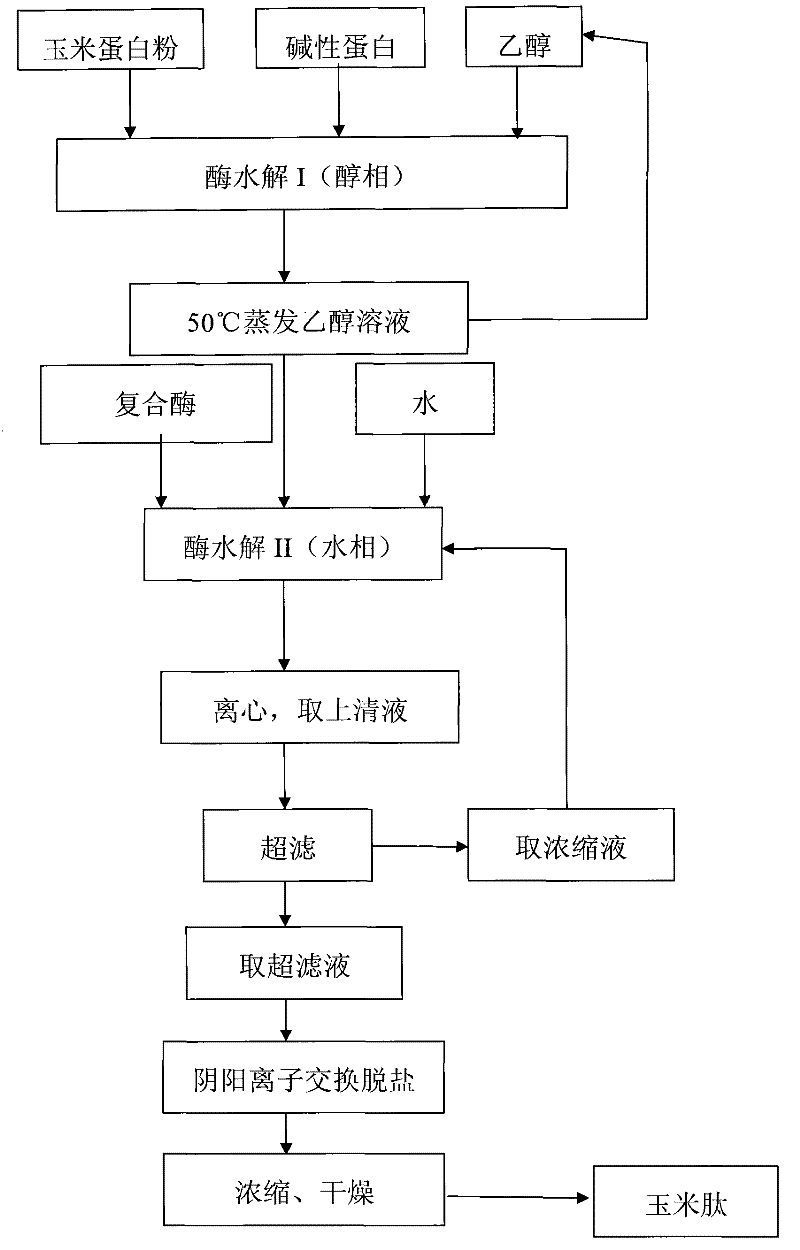

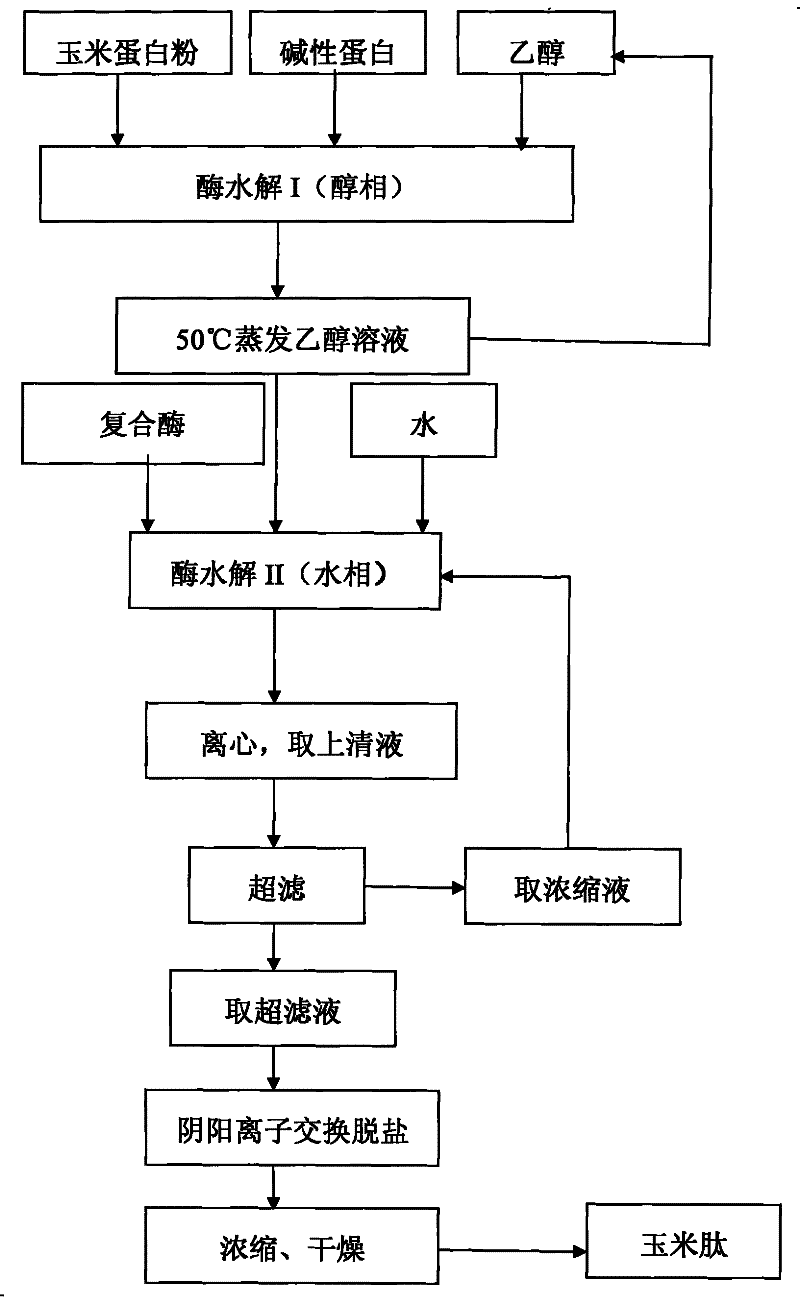

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of corn peptide, the method comprises the steps of:

[0038](A) Take 50g of corn gluten powder, add it to 2L of 90% ethanol solution, stir, heat the solution to 55°C, adjust the pH to 10.0 with NaOH solution, add 5g of alkaline protease, and in the alcohol phase under this condition Hydrolyze for 2 hours, use NaOH solution to keep the pH value at 10.0 during the enzymolysis process;

[0039] (B) After step (A), evaporate 1L of ethanol solution, add water to make up to the volume of the original hydrolyzate, stir evenly, heat the solution to 45°C, adjust the pH to 10.0 with NaOH solution, add 2g of compound enzyme, press here Hydrolyze in the alcohol phase for 20 minutes under the same conditions, and use NaOH solution to keep the pH value at 10.0 during the enzymolysis process;

[0040] (C) After step (B), adjust the pH to 3.0 with HCl solution, and centrifuge for 20 to 30 minutes at a centrifuge speed of 3000 r / m to obtain a supernatant, which is ...

Embodiment 2

[0048] A preparation method of corn peptide, the method comprises the steps of:

[0049] (A) Take 100g of corn gluten powder, add it to 2L of 80% ethanol solution, stir, heat the solution to 45°C, adjust the pH to 9.0 with NaOH solution, add 9g of alkaline protease, and use this condition in the alcohol phase Hydrolyze for 3 hours, and use NaOH solution to keep the pH value at 9.0 during the enzymolysis process;

[0050] (B) After step (A), evaporate 1000mL of ethanol solution, add water to make up the volume of the original hydrolyzate, stir evenly, heat the solution to 45°C, adjust the pH to 8.0 with NaOH solution, add 5g of compound enzyme, press here Hydrolyze in the alcohol phase for 30 minutes under the same conditions, and use NaOH solution to keep the pH value at 8.0 during the enzymolysis process;

[0051] (C) After step (B), adjust the pH to 4.5 with HCl solution, centrifuge at 3000 rpm for 15 minutes to obtain the supernatant, which is the crude corn peptide;

[0...

Embodiment 3

[0059] A preparation method of corn peptide, the method comprises the steps of:

[0060] (A) Take 500g of corn gluten powder, add it to 15L of 85% ethanol solution, stir, heat the solution to 50°C, adjust the pH to 8.5 with NaOH solution, add 50g of alkaline protease, and in the alcohol phase under this condition Hydrolyze for 3 hours, and use NaOH solution to keep the pH value at 8.5 during the enzymolysis process;

[0061] (B) After step (A), evaporate 10L of ethanol solution, add water to make up to the volume of the original hydrolyzate, stir evenly, heat the solution to 50°C, adjust the pH to 8.5 with NaOH solution, add 15g of compound enzyme, press here Hydrolyze in the alcohol phase for 40 minutes under conditions, and use NaOH solution to keep the pH value at 8.5 during the enzymolysis process;

[0062] (C) After step (B), adjust the pH to 4.0 with HCl solution, centrifuge at 3000 rpm for 15 minutes, and obtain the supernatant, which is the corn peptide crude liquid; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com