Method for preparing high-temperature superconductive coated conductor SrZrO3 buffer film

A coated conductor and high-temperature superconducting technology, which is applied in the field of preparation of high-temperature superconducting buffer layer films, can solve problems affecting the superconducting performance of ReBCO, and achieve the effects of reducing production costs, easy operation and control, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

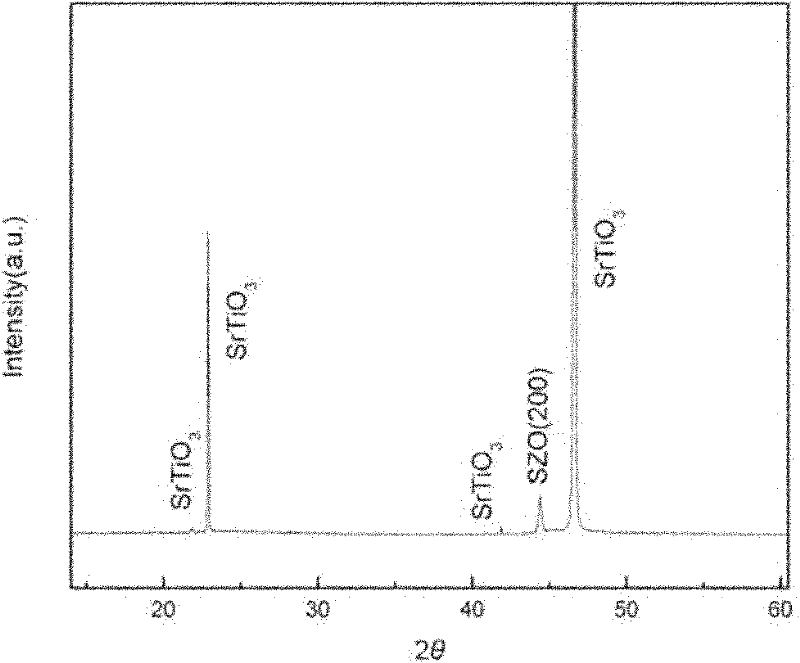

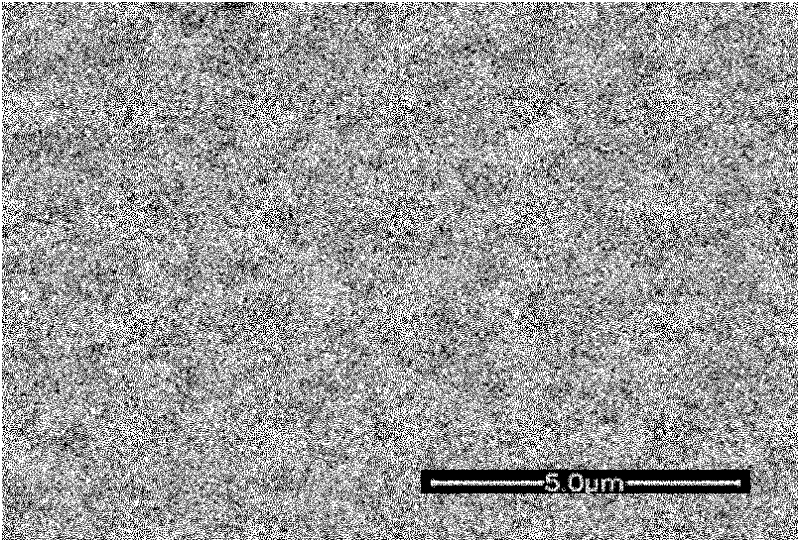

Examples

Embodiment 1

[0027] The preparation method of this example consists of the following steps in turn:

[0028] a, anhydrous solution preparation: strontium acetate and zirconium acetylacetonate are equal to the ratio of 1: 1 by the ion number ratio of strontium: zirconium, dissolve in propionic acid, form anhydrous solution;

[0029] b. Colloid preparation: Add polyvinyl butyral (PVB) to the anhydrous solution in step a to form a colloid; the amount of polyvinyl butyral (PVB) accounted for 5% of the total mass of the colloid.

[0030] c. Colloid coating and drying: coat the colloid prepared in step b on the substrate, and then dry; covered on the substrate. The temperature during drying was 150°C.

[0031] d. Thermal decomposition treatment: place the colloid-coated substrate in a sintering furnace, and feed argon into the sintering furnace to raise the furnace temperature from room temperature to 170°C at a rate of 1°C / min, and then at a rate of 0.9°C / min. The speed of min is raised to 5...

Embodiment 2

[0036] The preparation method of this example consists of the following steps in turn:

[0037] a, anhydrous solution preparation: strontium acetate and zirconium acetylacetonate are equal to the ratio of 1: 1 by the ion number ratio of strontium: zirconium, dissolve in propionic acid, form anhydrous solution;

[0038] b. Colloid preparation: Add polyvinyl butyral (PVB) to the anhydrous solution in step a to form a colloid; the amount of polyvinyl butyral (PVB) added accounts for 4% of the total mass of the colloid.

[0039] c. Colloid coating and drying: coat the colloid prepared in step b on the substrate, and then dry; covered on the substrate. The temperature during drying was 100°C.

[0040] d. Thermal decomposition treatment: place the colloid-coated substrate in a sintering furnace, and feed argon into the sintering furnace to raise the furnace temperature from room temperature to 240°C at a rate of 1°C / min, and then increase the temperature at a rate of 0.1°C / min. The...

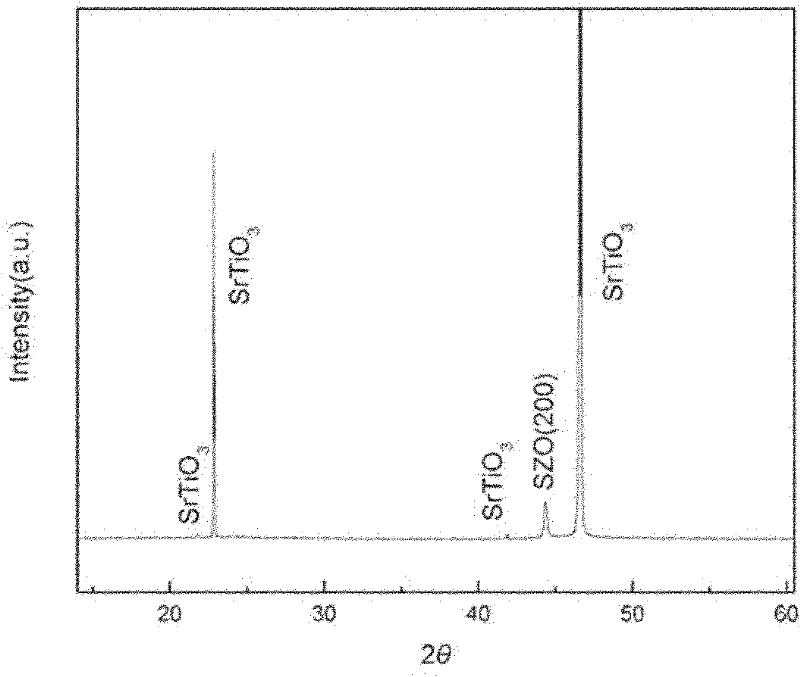

Embodiment 3

[0045] The preparation method of this example consists of the following steps in turn:

[0046] a, anhydrous solution preparation: strontium acetate and zirconium acetylacetonate are equal to the ratio of 1: 1 by the ion number ratio of strontium: zirconium, dissolve in propionic acid, form anhydrous solution;

[0047] b. Colloid preparation: Add polyvinyl butyral (PVB) to the anhydrous solution in step a to form a colloid; the amount of polyvinyl butyral (PVB) added accounts for 3% of the total mass of the colloid.

[0048] c. Colloid coating and drying: coat the colloid prepared in step b on the substrate, and then dry; covered on the substrate. The temperature during drying was 200°C.

[0049] d. Thermal decomposition treatment: place the colloid-coated substrate in a sintering furnace, and feed argon gas into the sintering furnace to raise the furnace temperature from room temperature to 190°C at 1°C / min, and then at 0.4°C / min The speed of min is raised to 530°C, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com