Glass packaging structure and manufacturing method thereof

A technology of glass encapsulation and manufacturing method, which is applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc. It can solve problems such as long time consumption, air leakage, and rising production costs, and achieve cost saving and strong Anti-moisture performance, the effect of avoiding the risk of air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

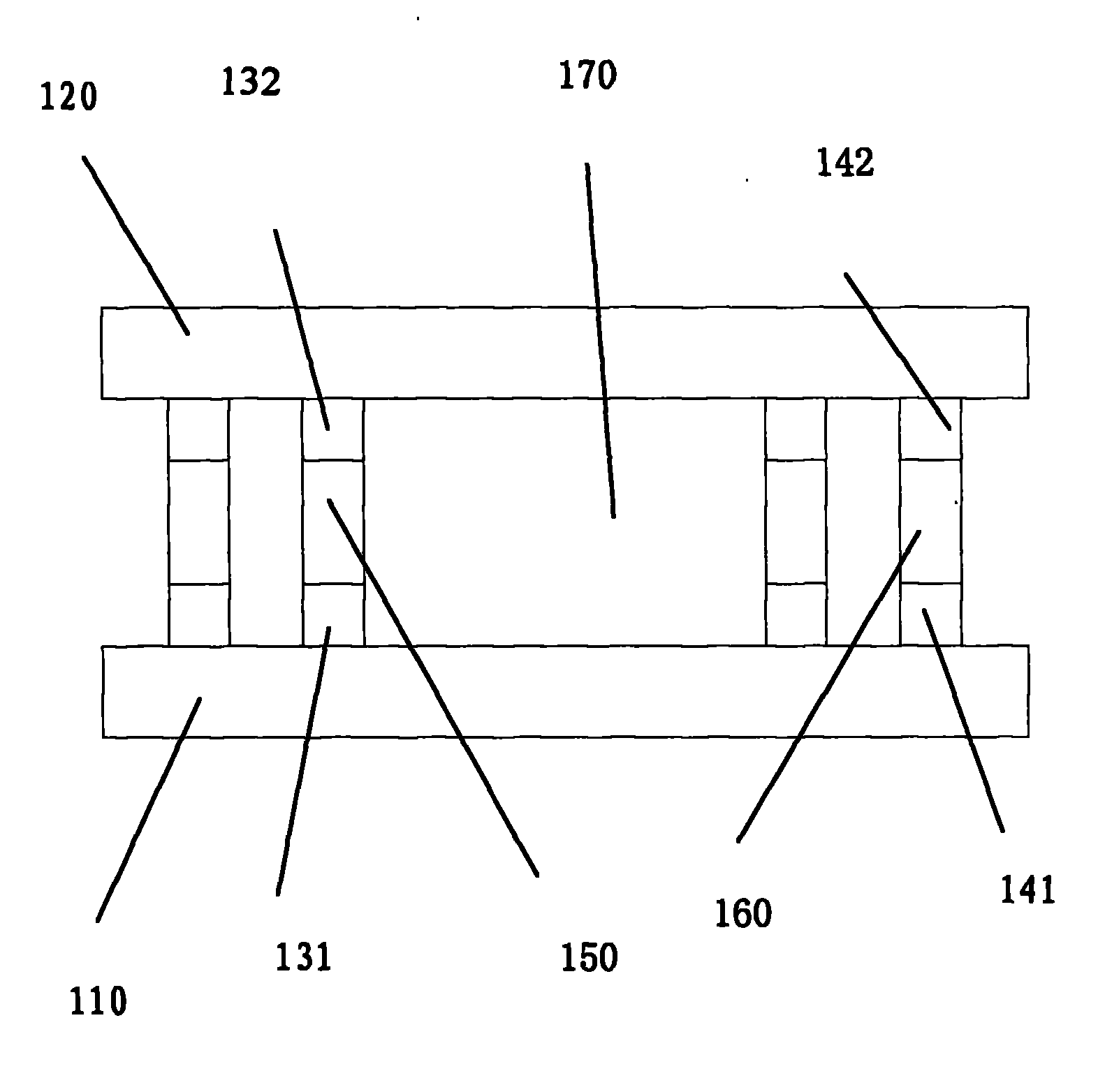

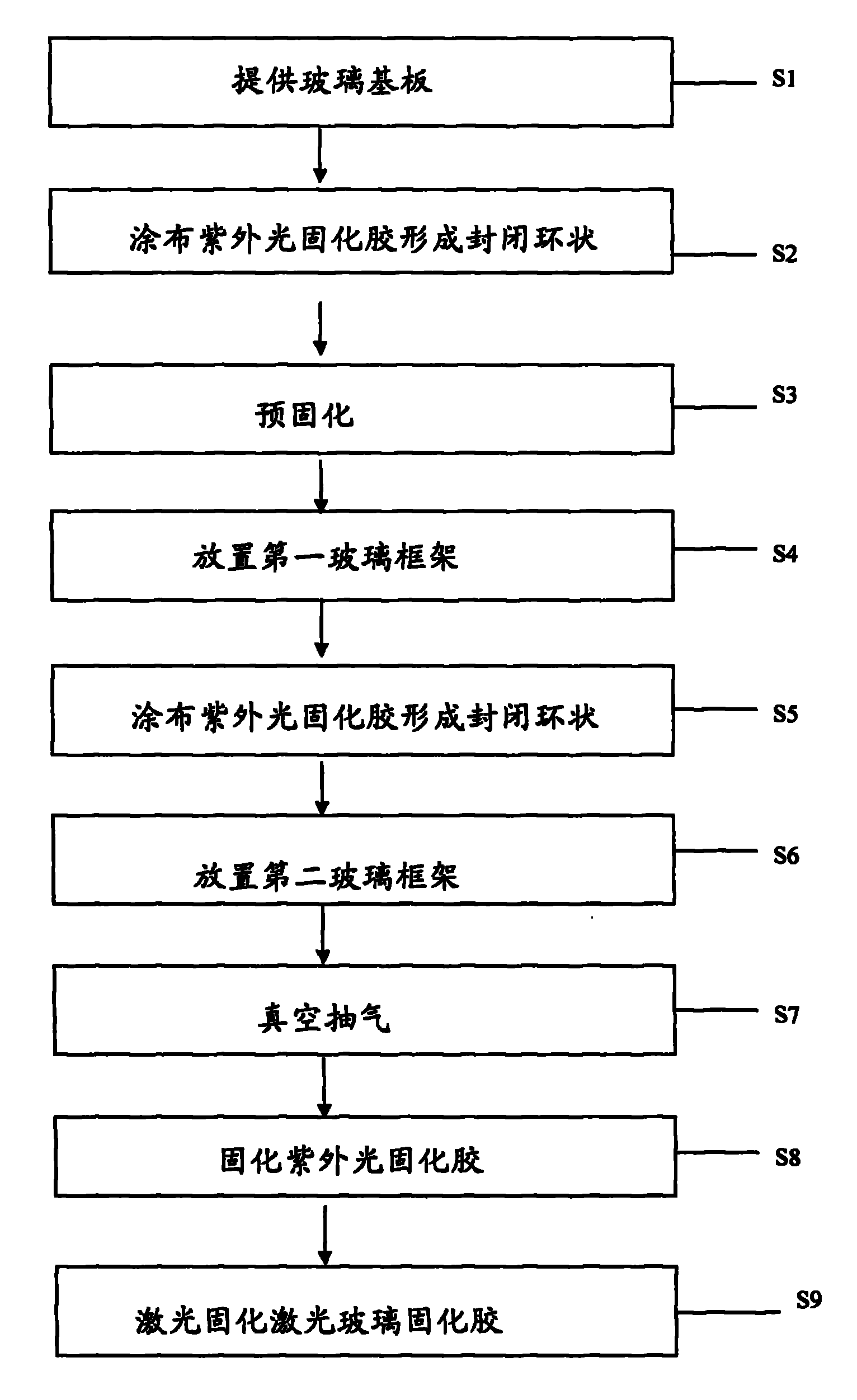

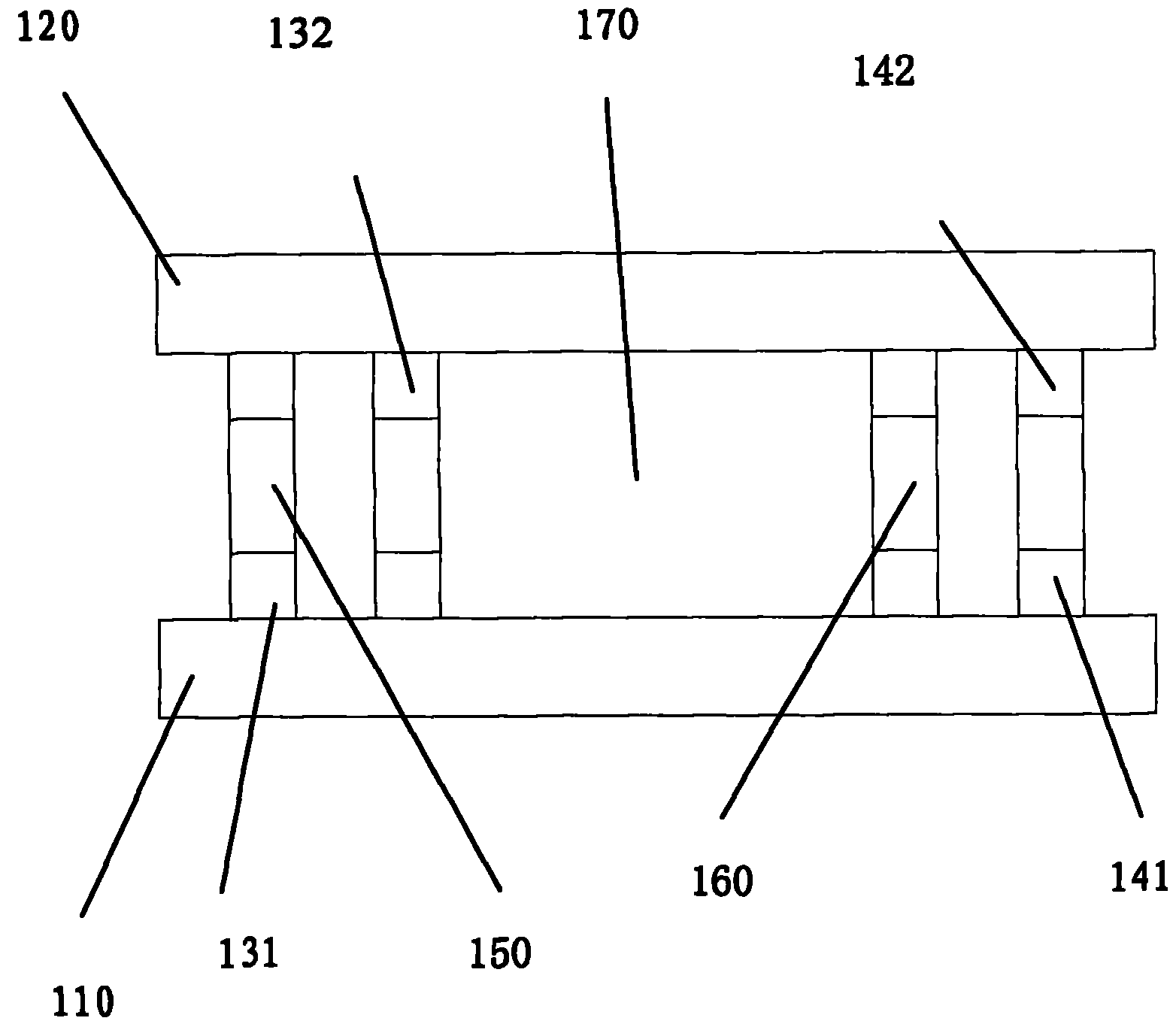

[0022] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. figure 1 A cross-sectional view of a glass package structure according to an aspect of the present invention is shown. refer to figure 1 , the glass package structure includes: a first glass substrate 110, a second glass substrate 120, a first laser curing glue 131, a second laser curing glue 132, a first ultraviolet light curing glue 141, a second ultraviolet light curing glue 142, a first The glass frame 150 and the second glass frame 160 . Wherein, the second glass substrate 120 is arranged parallel to one side of the first glass substrate 110, the first laser curing glue 131 is located on a surface of the first glass substrate 110, and forms a first closed ring, and the second laser curing glue 132 It is located on the side of the second glass substrate 120 corresponding to the first glass substrate 110 and forms a second closed ring, the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com