Transparent security box of cable intermediate head

A technology of cable intermediate joint and safety box, applied in the direction of connection insulation, etc., can solve the problems such as opaque safety box, difficult to visually understand the state and environment of cable intermediate joint in the box, and safety box failure difficult to be detected in advance and dealt with in time. Accident prevention, excellent sealing and waterproof performance, good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

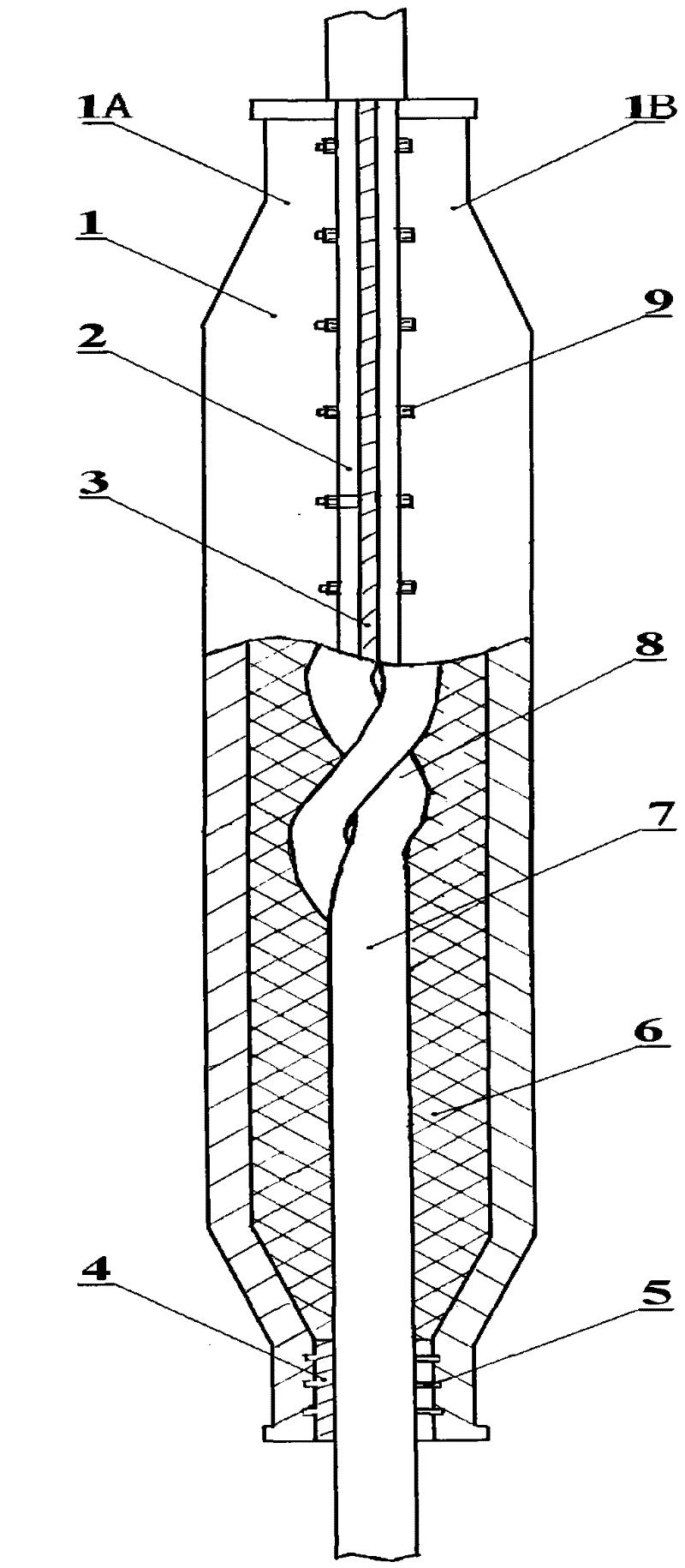

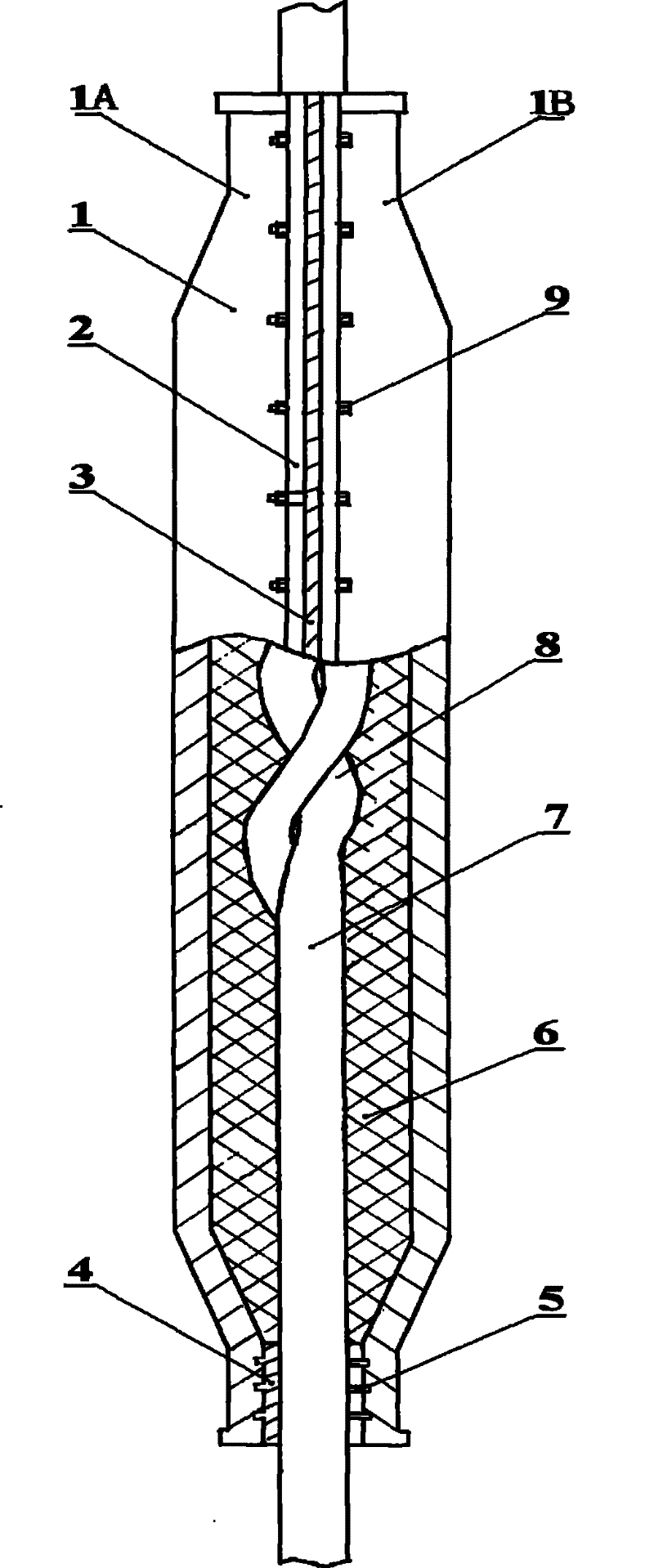

[0025] Such as figure 1 As shown, the two semi-cylindrical bodies 1-1A, 1-1B transparent safety box 1 with two small middle convex parts are injection molded with modified polycarbonate resin, and the two semi-cylindrical bodies 1-1A, 1- 1B The interface of the transparent safety box 1 is injection-molded with a flange 2, and a sealing sheet 3 is provided on the joint surface of the flange 2, and a ring groove 5 is provided in the box hole at both ends of the small transparent safety box 1. The two ends of the box hole 4 are fitted with a synthetic rubber sealing sleeve 4 with good elasticity and high strength, which is used to set the cable 7, the cable joint 8 is filled with fireproof material 6, and the transparent safety box 1 sets the two semi-cylindrical bodies 1-1A of the cable 7 , between the flanges of 1-1B, a synthetic rubber sealing sheet 3 with good elasticity and high strength is installed, and the upper and lower half cylinders 1-1A and 1-1B are fixed with fasten...

Embodiment 2

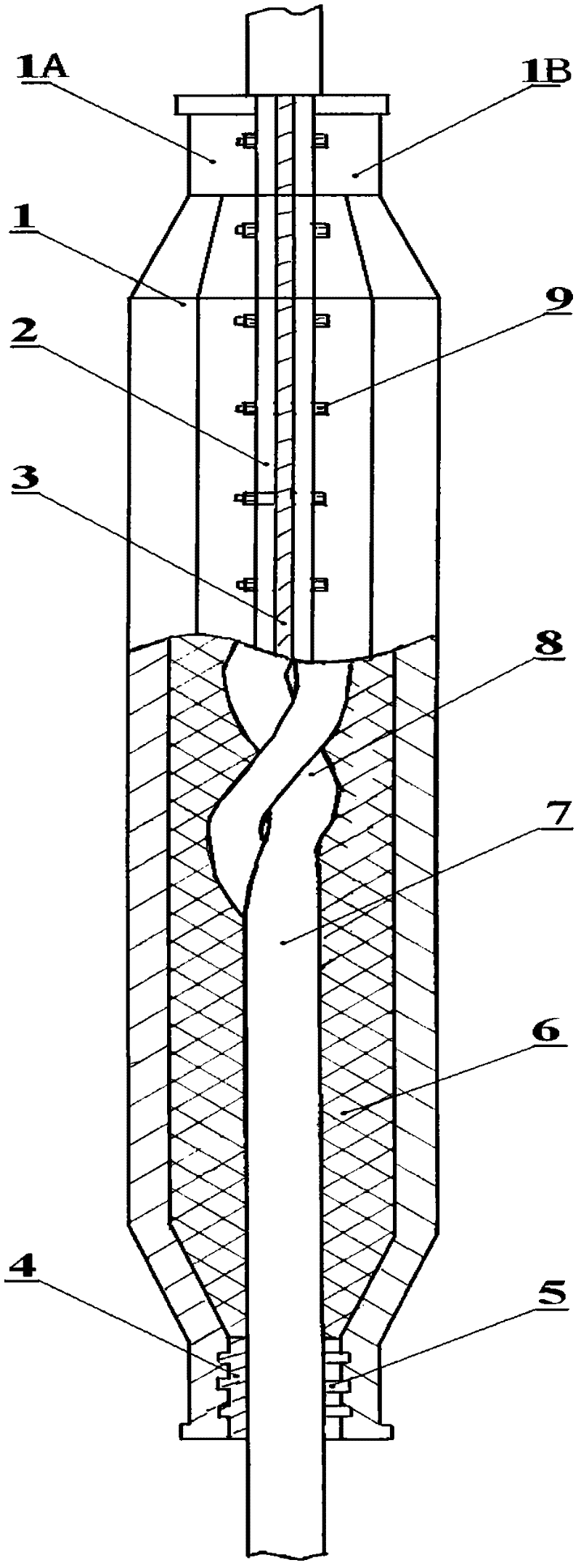

[0027] Such as figure 2 As shown, the two semi-prisms 2-1A and 2-1B transparent safety box 1 with two small central bulges at both ends are injection-molded with polycarbonate resin, and the two semi-prisms 2-1A and 2-1B are transparent The interface of the safety box 1 is injection-moulded with a flange 2, and a sealing sheet 3 is provided on the joint surface of the flange 2. A ring groove 5 is provided in the box hole 4 at both ends of the small transparent safety box 1, and a ring groove 5 is provided at both ends of the small transparent safety box 1. The box hole 4 is equipped with a modified rubber sealing sleeve 4 with good elasticity and high strength, which is used to cover the cable 7, the cable joint 8 is filled with fireproof material 6, and the two semi-prisms 2-1A, 2- of the transparent safety box 1 A modified rubber sealing sheet 3 with good elasticity and high strength is installed between the flanges 2 of 1B, and the sealed transparent safety box 1 that fixe...

Embodiment 3

[0029] Such as figure 1 As shown, the two semi-cylindrical bodies 1-1A, 1-1B transparent safety box 1 with two small middle convex parts are injection molded with modified polycarbonate resin, and the two semi-cylindrical bodies 1-1A, 1- 1B The interface of the transparent safety box 1 is injection-molded with a flange 2, and the joint surface of the flange 2 is provided with a sealing sheet 3, and a modified polyurethane resin with good elasticity and high strength is set in the small two-end box holes 4 of the transparent safety box 1 The sealing sleeve 4 is used to set the cable 7, the cable joint 8 is filled with fireproof material 6, and the two semi-cylindrical bodies of the transparent safety box 1 figure 1 A modified polyurethane resin sealing sheet 3 with good elasticity and high strength is installed between the flanges 2 of the flange 2, and the sealed transparent safety box 1 that fixes the two semi-cylindrical bodies 1-1A and 1-1B as one with fastening bolts 9. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com