Capsularhexis device with flexible heating element

A resistive heating element, superelastic technology, applied in the field of cataract surgery, can solve the problems of increasing operation length and complexity, vitreous loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

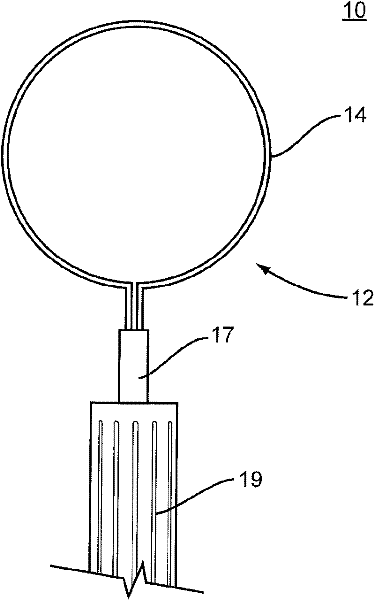

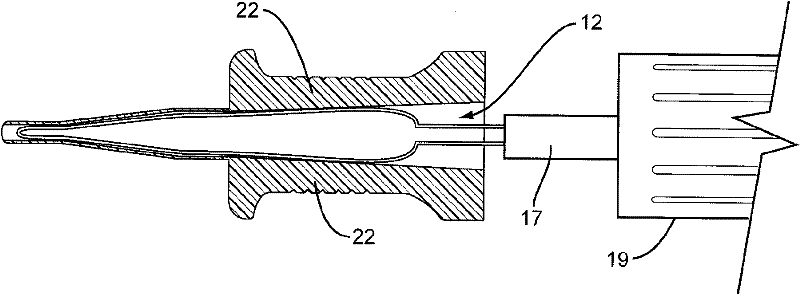

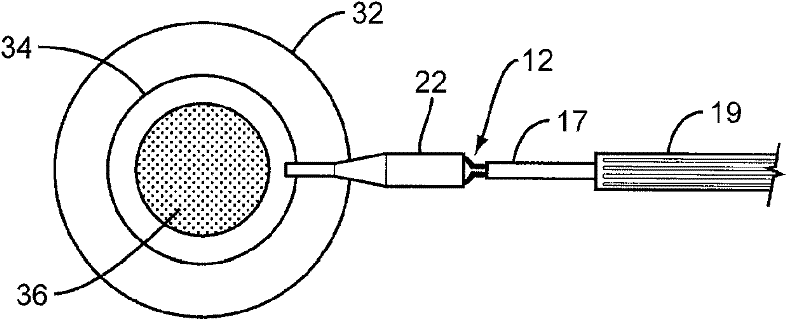

[0020] Various embodiments of the present invention provide devices and corresponding methods for operating a capsulorhexis. In particular, the present invention relates to a surgical instrument known as a capsulorhexis device that can be positioned within the anterior chamber of the eye through a small incision to perform a capsulorhexis or capsulotomy. This procedure facilitates phacoemulsification of cataract lenses and insertion of artificial intraocular lenses (IOLs).

[0021] US Patent Application Publication No. 2006 / 010061 describes a capsulhexis device comprising a circular and flexible ring made of elastomeric or acrylate or thermoplastic material. Embedded within each of the various embodiments of the flexible ring is a resistive heating element or a pair of bipolar electrodes, powered according to known techniques to generate localized heating on the anterior capsule, thereby defining a weakened boundary so that the circular The part of the capsule inside the ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com