Jaw impacting and rubbing ultrafine crusher

A technology of fine crushing and crushing mechanism, which is applied in the field of material crushing equipment and ultra-fine crushers. It can solve the problems of large particle size of materials, and achieve the effects of easy operation, simple structure, and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

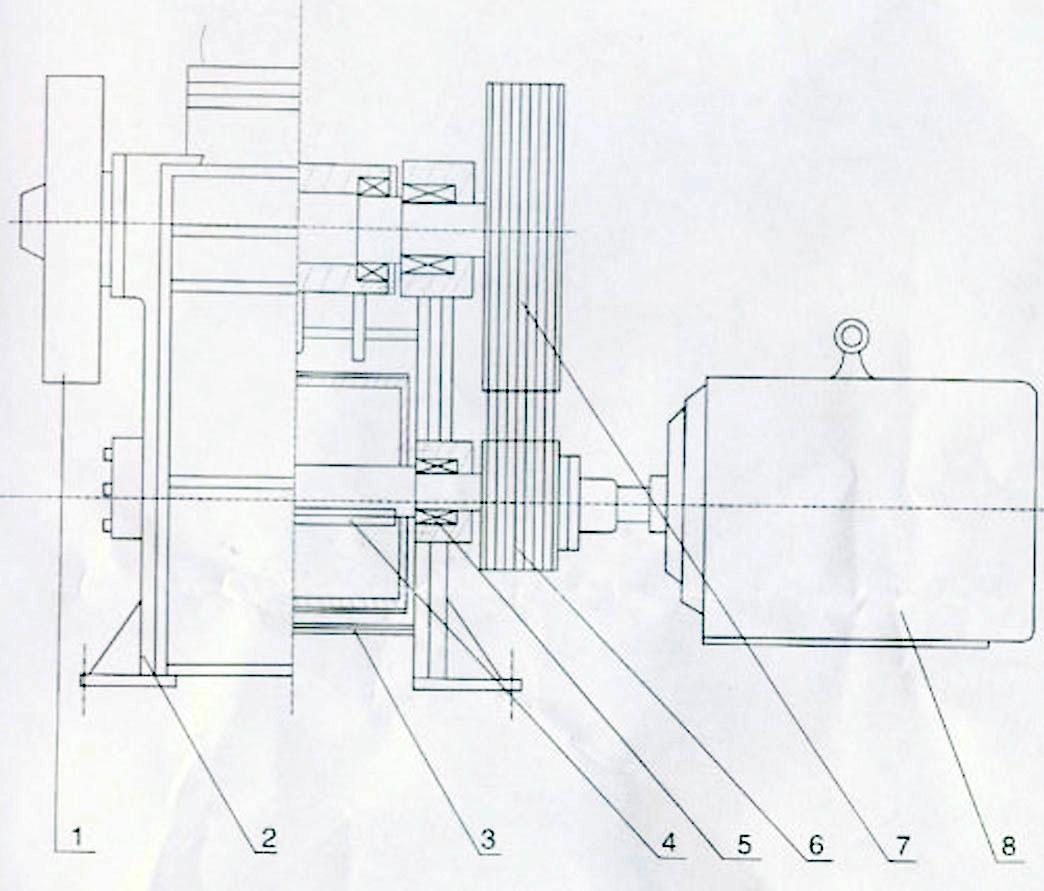

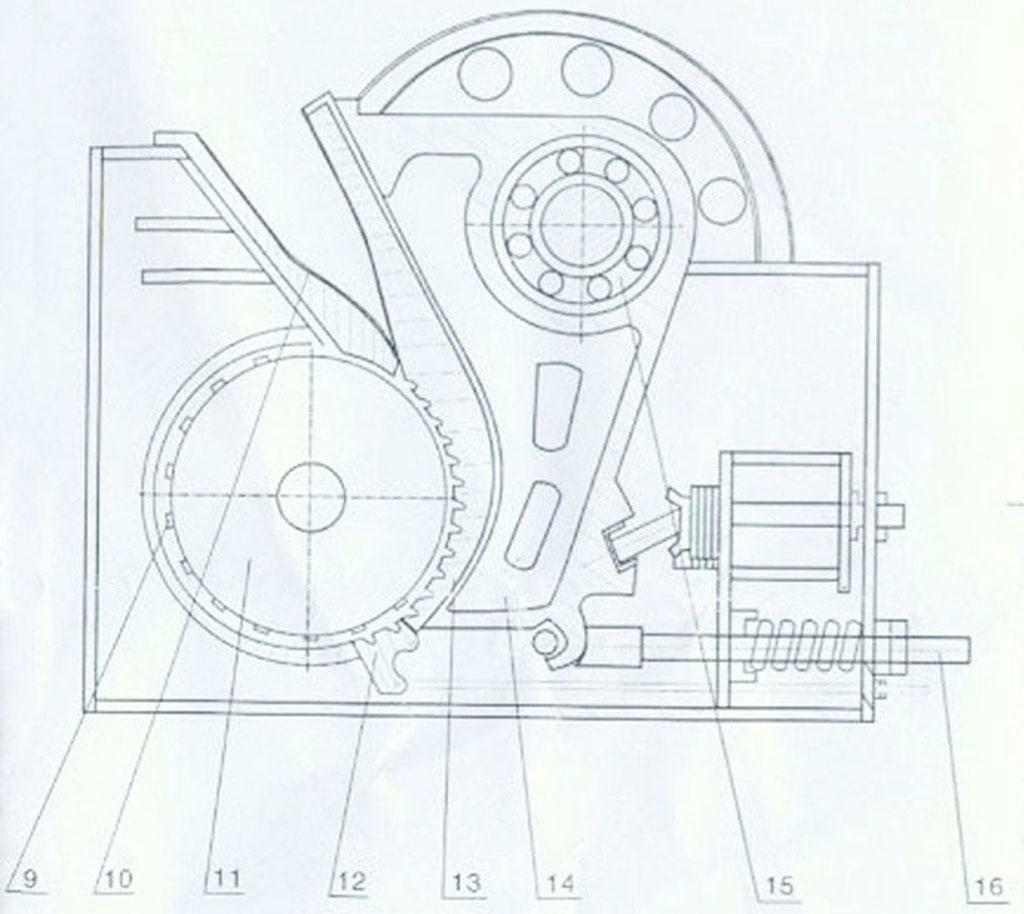

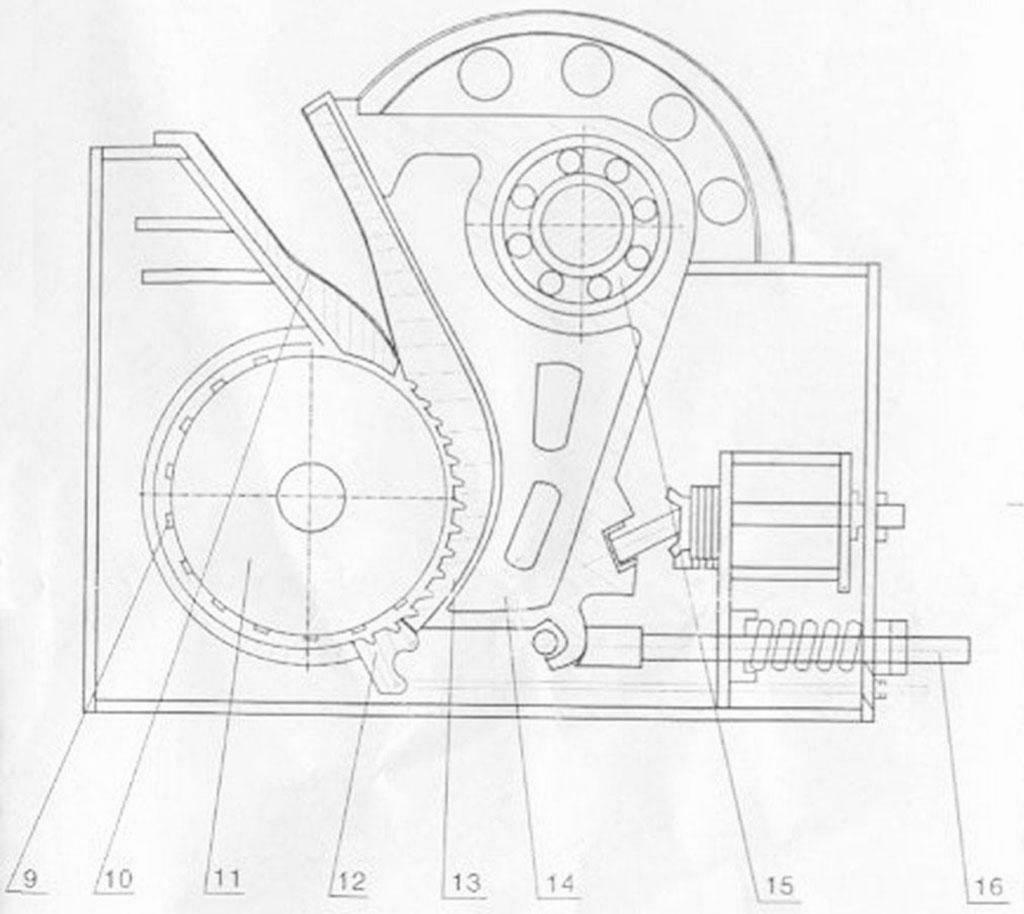

[0012] Such as figure 2 The shown jaw-grabbing ultra-fine crusher includes a driving mechanism, a body, a crushing mechanism, the driving mechanism is connected to the body, a crushing mechanism is arranged in the body, and an adjuster 16 arranged on the crushing mechanism is also included. The crushing mechanism It includes a fixed jaw plate 10 and a movable jaw body 14. The upper section of the fixed jaw plate 10 is a linear inclined surface, and the lower section is a cylindrical rubbing roller 11. There are wipers and blow bars 9 on the surface of the rubbing roller 11. The upper section of the movable jaw body 14 is a linear inclined surface, and the lower section is a movable jaw plate 13 that is provided with reverse teeth on the cylindrical inclined surface of the rubbing roller 11 .

[0013] The bottom of the contact surface between the rubbing roller 11 and the movable jaw plate 13 is provided with a fine rubbing jaw plate 12 .

[0014] The upper section of the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com