Use of liquid crystal display and method for recycling the same

A technology of recycling, raw materials, applied in the direction of chemical instruments and methods, instruments, other chemical processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0058] Example 1 (selective melting)

[0059] In each case, the coated STN-LCD and TFT-LCD consisted of two glass plates, two polarizing films, and liquid crystals, which were crushed to a size of about 1 to 3 cm, respectively. In each case, 100 g of chips were weighed out and then mixed. Alumina grooves were connected at an angle of 20°, and the mixture was introduced onto the higher portion. Slowly heat up to 1400°C by using an oxygen burner. The parts of the LCD started to melt from 950°C, while emitting very strong smoke, and the polarizing film burned and flowed down into the tank. The residue starts to melt only at 1200°C and flows down into the tank. With sensitive collection of fragments, about 40% STN glass, 40% TFT glass and 20% fragments containing a mixture of STN and TFT glass can be obtained.

example 2

[0060] Example 2 (metallurgy)

[0061] The experiments were carried out in a horizontal position, the gas furnace had a diameter of about 3.5 m and a length of 4 m.

[0062] The LCD mixture used in these experiments consisted of about 40% TFT-LCD and about 60% STN-LCD. The LCD is mostly in intact form and partly - due to the transfer operation - in broken form, ie in diameter sizes from 10 to 50 cm. In some cases, the electronics are still present on the LCD. LCDs are mainly sourced from electrical recycling companies that have disassembled, collected and stored LCDs.

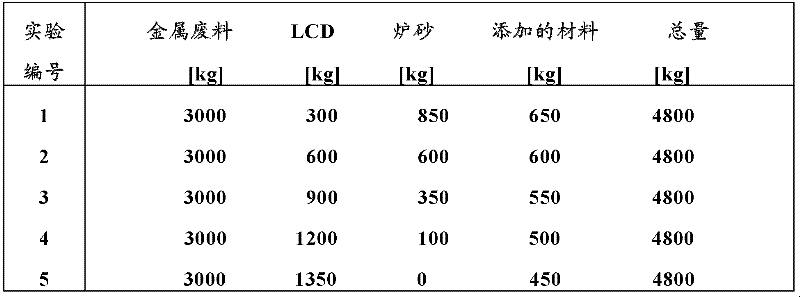

[0063] Using a bucket wheel loading device, metal scrap, LCD mix, furnace sand and additive materials including coal are introduced and mixed slowly into a mixer with internal blades having a diameter of approximately 10 m 3 capacity. The precise composition is described in Table 1. During this mixing operation, the LCDs were at least partially broken, so that most of the LCDs had a size of 3 to 30 cm afte...

example 3

[0074] Example 3 (Industrial waste incinerator)

[0075] 176 (120l) barrels each containing about 100kg LCD, ie a total of about 18t LCD are used. Here the LCD is mainly in unbroken form, ie 10 to 50 cm in diameter size. Here the mixture consists of about 70% TFT-LCD and about 30% STN-LCD. In some cases, the electronics are still present in the LCD. LCDs are mainly sourced from electrical recycling companies that have disassembled, collected and stored LCDs.

[0076]Industrial waste to be incinerated, such as acids, polluted organic solvents or solids, is incinerated in a large industrial waste rotary tube incinerator, which has a diameter of 3.5m and a length of 11m, using temperatures from about 1200 to 1300°C gas. Industrial waste and LCDs present in drums are introduced into the upper part of the furnace by means of grabbers. Because the furnace is constantly kept at a temperature of 1200 to 1300°C, the barrel bursts immediately upon introduction. LCDs are introduced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com