Welding gun for flux-cored wire

A flux-cored welding wire and welding torch technology, which is applied in the field of welding torches, can solve problems such as large carbon dioxide emissions, high welding machine costs, and inconvenient use, and achieve the effects of reducing the burden of use, reducing weight, and reducing manufacturing and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

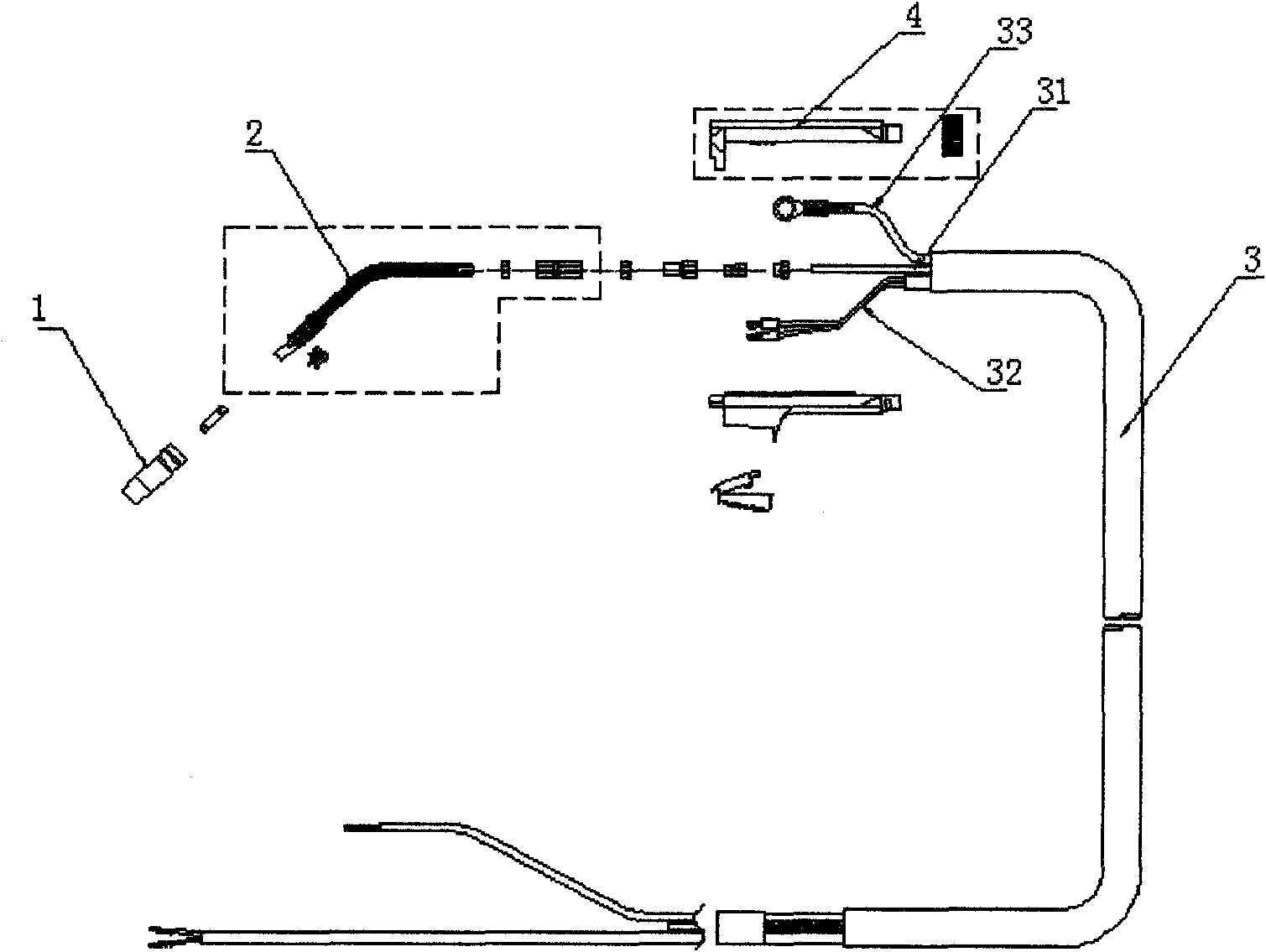

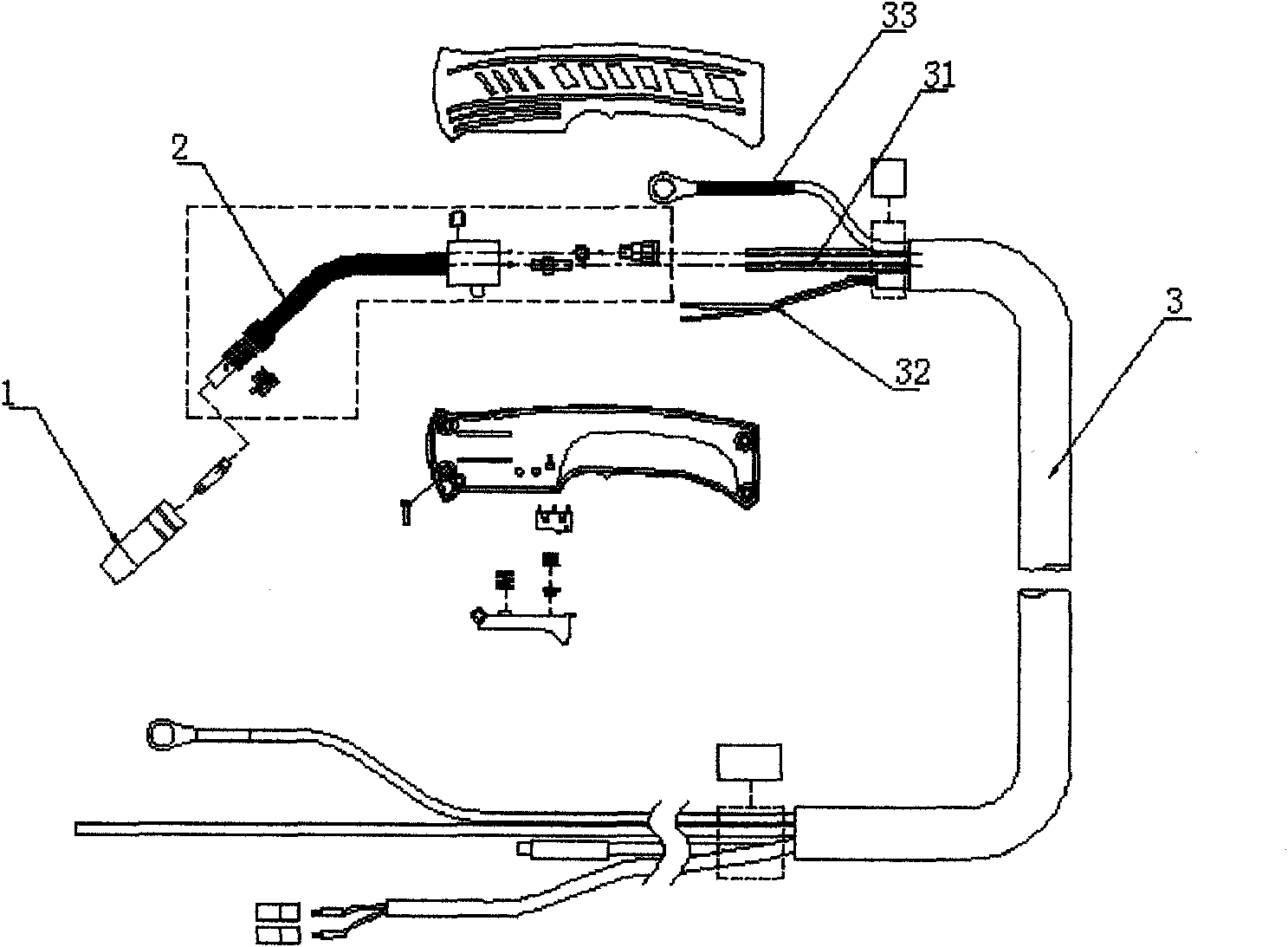

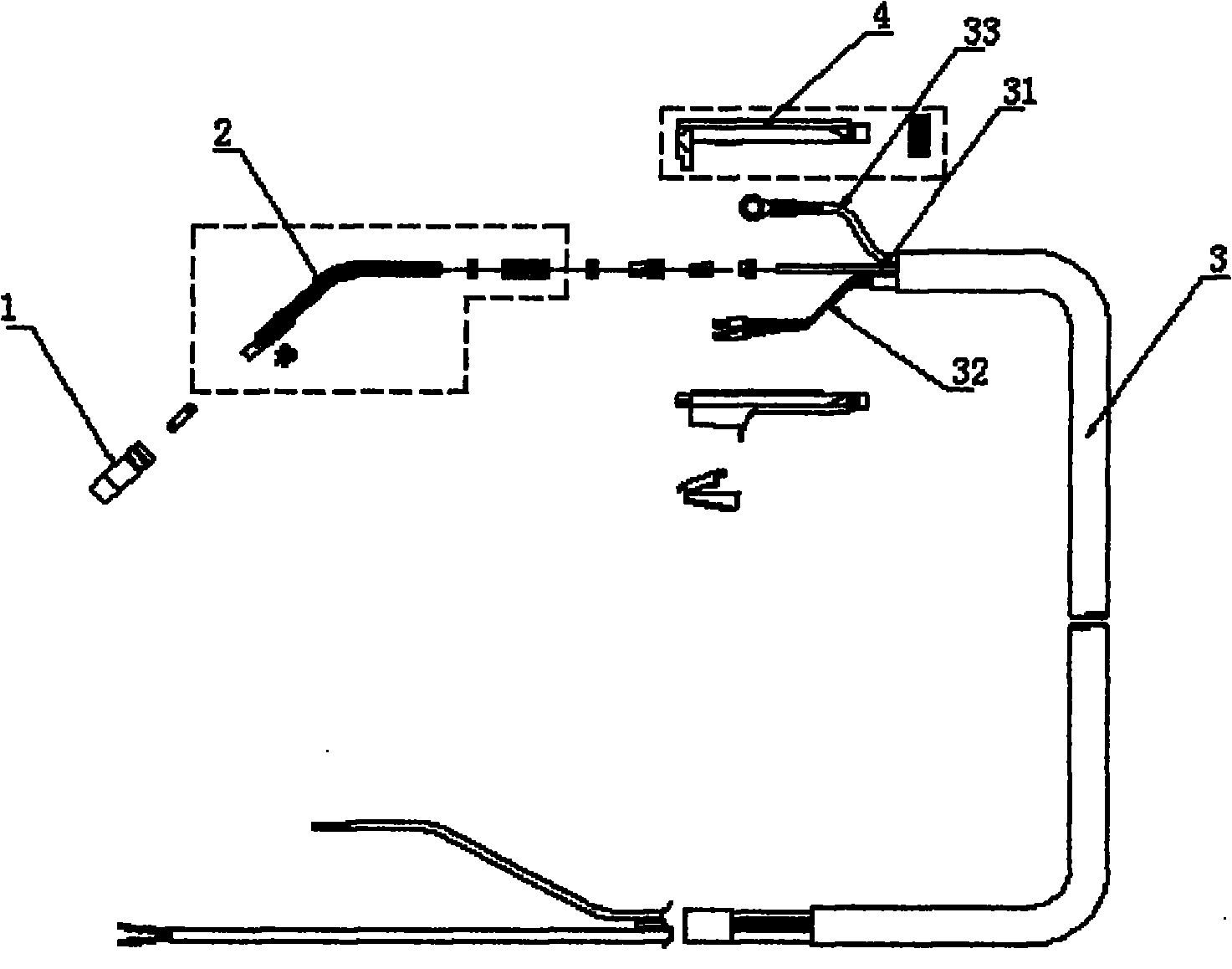

[0009] Embodiment: A welding torch for flux-cored welding wire, comprising a burner 1, an elbow 2 and a cable sleeve 3, one end of the burner 1 communicates with the other end of the elbow 2 and is fixedly connected, and one end of the elbow 2 is connected to the cable sleeve 3. Fixed connection, the cable casing 3 is provided with a welding wire tube 31 and a cable group, and the cable group is composed of a cable 32 and a switch wire 33. Since this welding torch is used for flux-cored wire, this welding wire has a flux core for protection without Then carbon dioxide is used for protection, and the gas pipe is removed in the cable group, which effectively reduces the weight of the welding torch, which also reduces the burden on the user. In addition, it also avoids repeated protection during welding, cancels the use of carbon dioxide, and conforms to modern low-carbon environmental protection concept.

[0010] A handle 4 is also provided on the outer wall of one end of the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com