Packing box for numerical control motors

A numerical control motor and packaging box technology, applied in the field of packaging, can solve the problems of inability to adapt to multi-type motor packaging, poor safety, etc., and achieve good shock-resistant buffering effect, strong adaptability, and ensure the effect of safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail in conjunction with the above drawings.

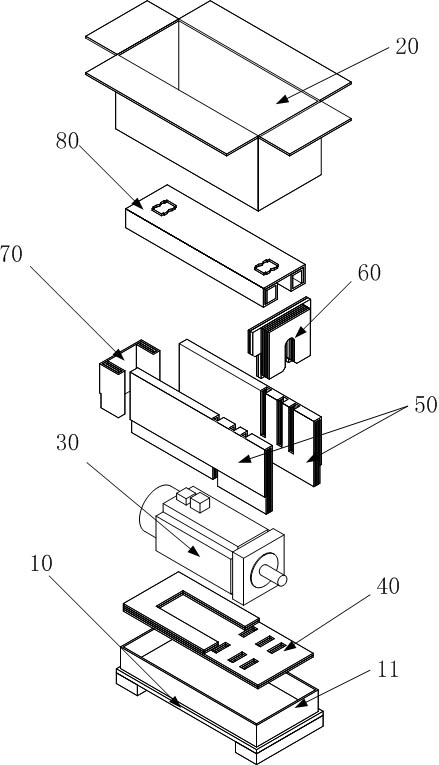

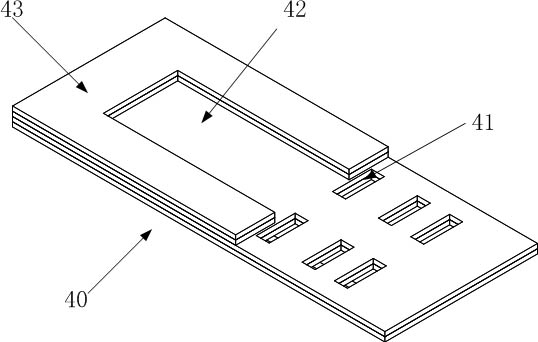

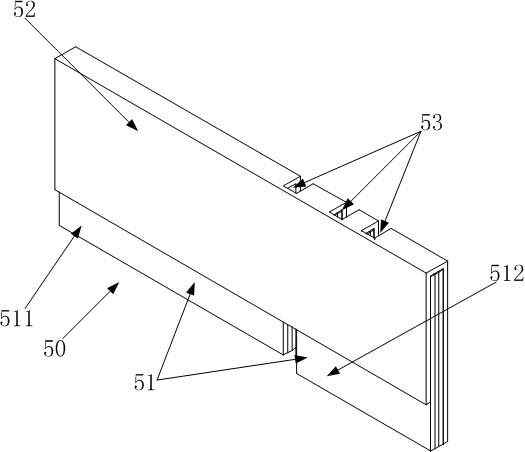

[0014] Depend on figure 1 It can be seen from the figure that this kind of numerical control motor packaging box includes a chassis 10, an upper box 20 that is fastened with the chassis 10 to form a packaging box, and a cushioning filling body arranged in the above-mentioned packaging box. The cushioning filling body includes a bottom positioning mechanism 40, Two side buffer mechanisms 50, a front-end positioning mechanism 60, a rear-end support mechanism 70 and a top buffer mechanism 80, the bottom positioning mechanism 40 is placed on the chassis 10, and the two side buffer mechanisms 50 are separately placed on the bottom On both sides of the positioning mechanism 40, the front positioning mechanism 60 and the rear supporting mechanism 70 are placed at the front and rear ends of the bottom positioning mechanism 40, and the top buffer mechanism 80 is pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com