Anti-icing passage system with functions of precooling and backheating

A technology of anti-icing system and air intake channel, which is applied in the direction of jet propulsion device, gas turbine device, machine/engine, etc., can solve the problems of energy waste, achieve the effect of reducing impact, reducing the amount of bleed air in the system, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail through specific embodiments below.

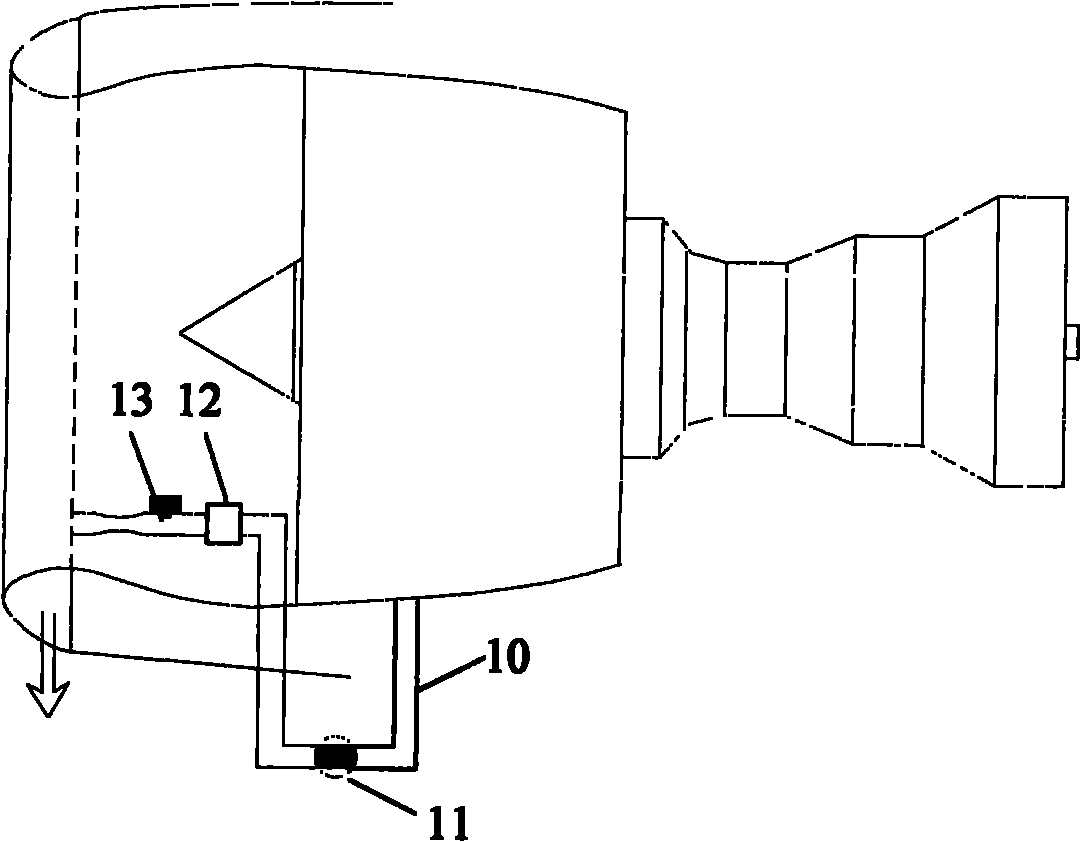

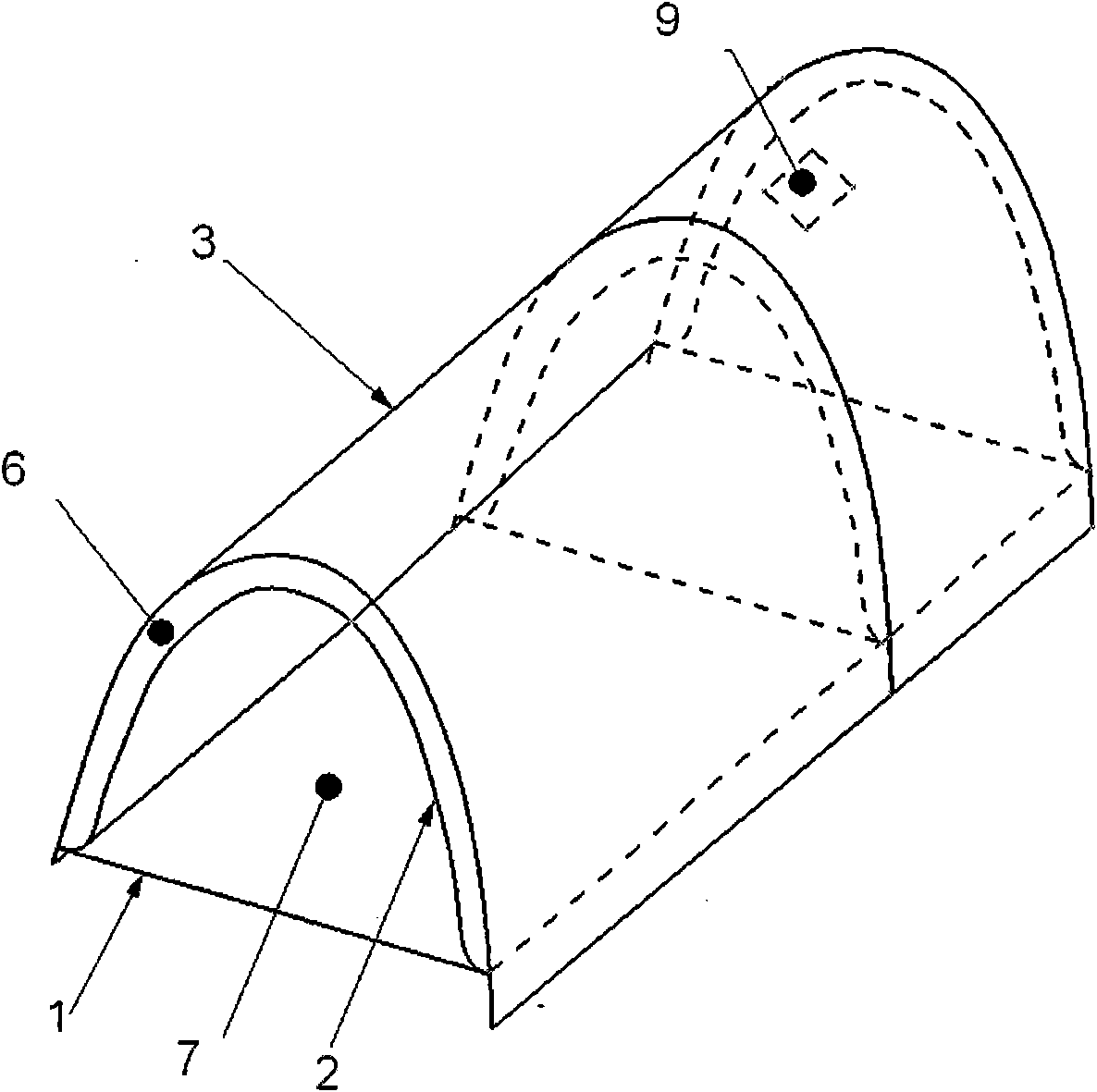

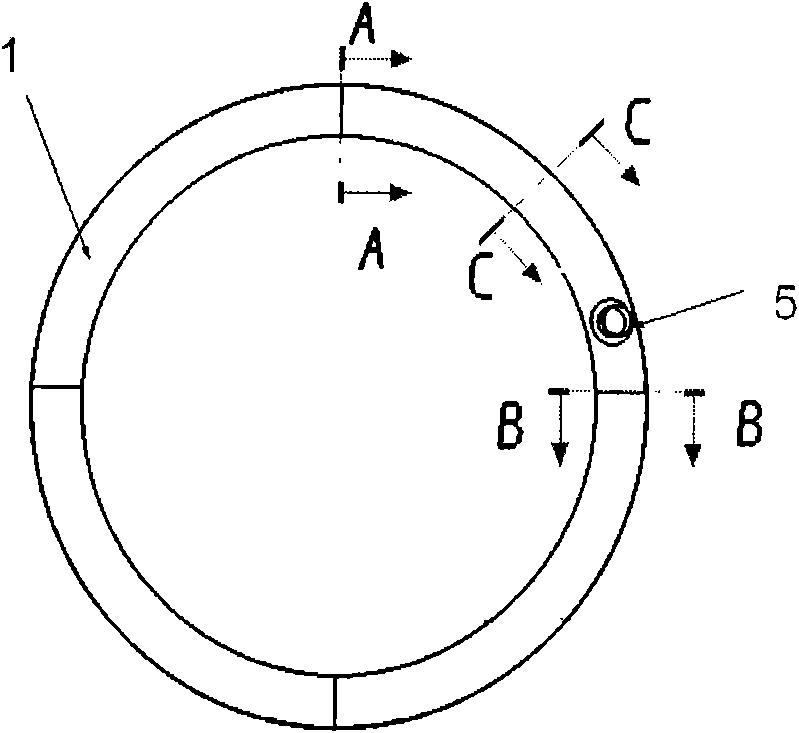

[0032] Such as image 3 Shown: The hot air of the system enters the front edge anti-icing chamber from the inlet of the air intake duct 5, and the anti-icing chamber is divided into two parts, the inner and outer parts. The inner part is composed of a partition 1 and an inner skin 2 , and the outer part is composed of an inner skin 2 and an outer skin 3 . Since the air flow enters the inner channel 6, there are two directions of flow to the communication hole 9 between the inner channel 6 and the outer channel 7. The flow paths in the two flow directions are different, and there are different flow resistance losses along the way, which will As a result, the gas flow in the two directions is inconsistent. In order to match the flow resistance in the two directions, a restrictor ring 8 is set on the part of the inner channel 6 with less resistance. The purpose of the restricto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com