High-efficiency and energy-saving furnace end and heating system

A high-efficiency energy-saving, burner technology, applied in hot water central heating systems, heating systems, household heating, etc., can solve the problems of low efficiency, high cost, time-consuming maintenance, etc., to reduce noise, eliminate howling, Maintenance time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

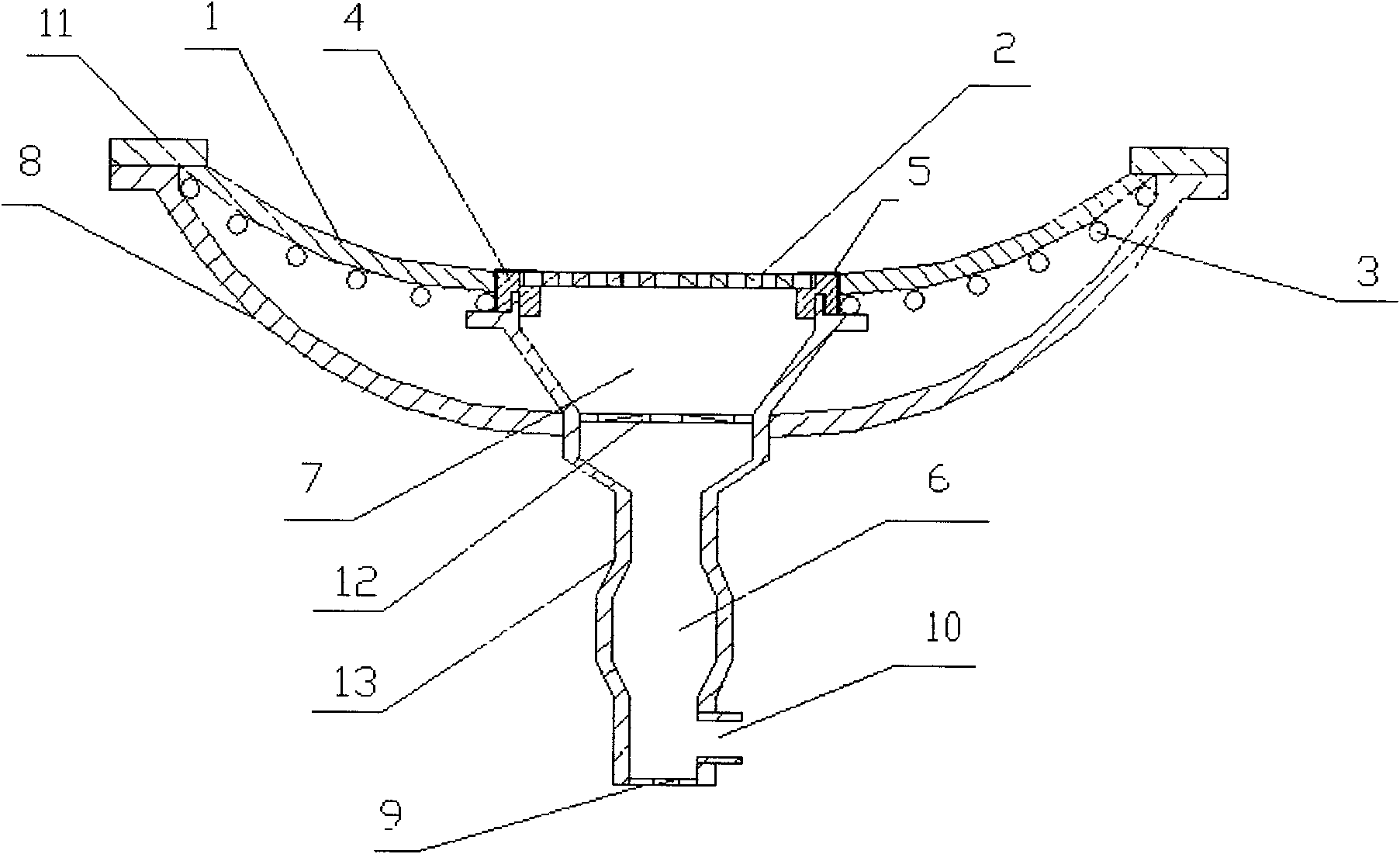

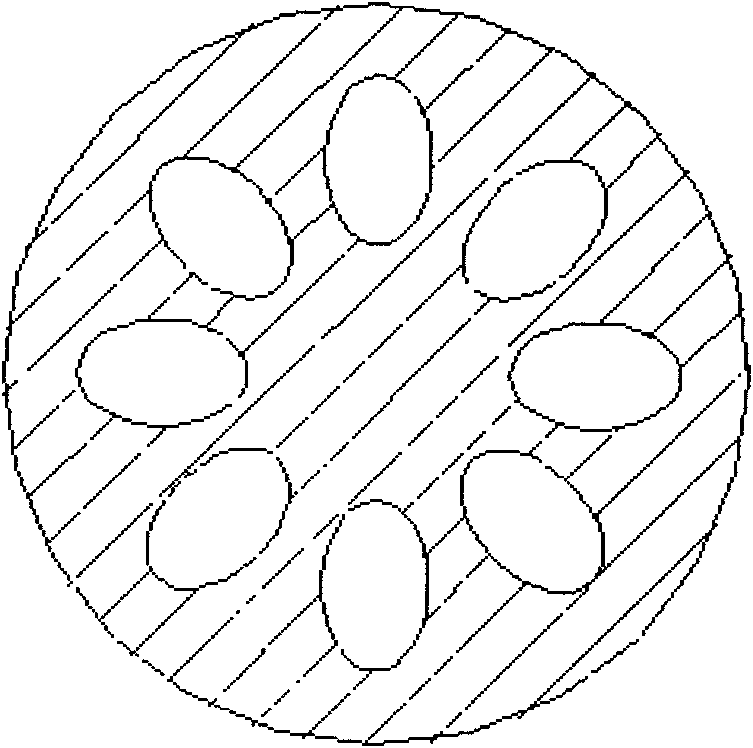

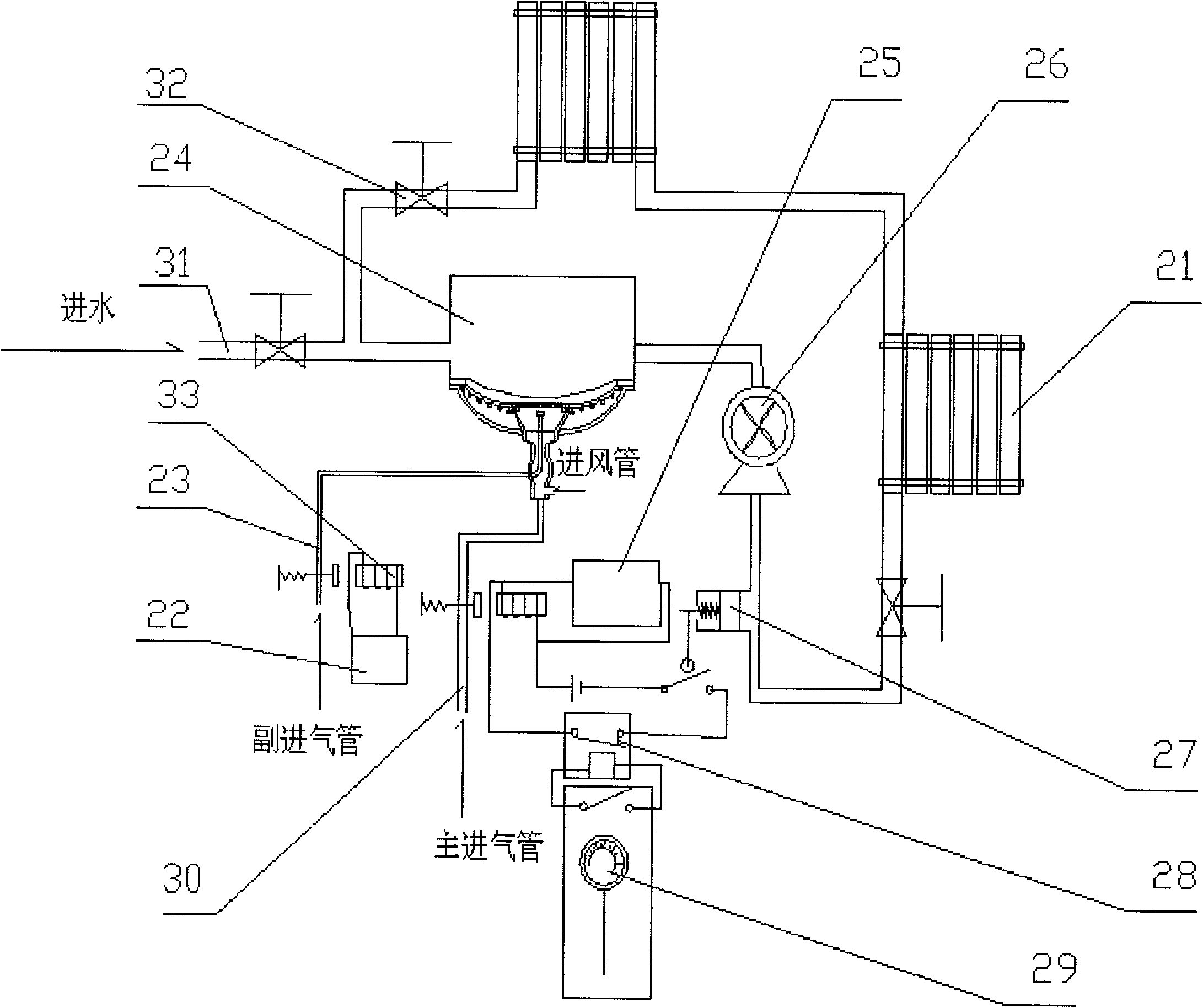

[0028] figure 1 It is a structural diagram of the high-efficiency and energy-saving furnace head of the present invention. The high-efficiency and energy-saving burner head of the present invention comprises a ceramic plate 1, a combustion plate 2, a water pipe 3, a furnace basin 8, a furnace core 13, a bushing 9, a fan duct inlet 10 and a partition 12, and the furnace core 13 inner cavity passes through the partition The plate 12 is divided into a first mixing chamber 6 and a second mixing chamber 7. The center of the bushing 9 is provided with a copper pipe as a gas inlet. The first mixing chamber 6 is provided with a fan duct inlet 10. Above the second mixing chamber 7 It is a combustion disc, and the surface layer of the furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com