Train windscreen test device for high-speed motor train unit

A high-speed EMU and test device technology, which is applied in the direction of railway vehicle testing, etc., can solve the problem that the test device cannot keep up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

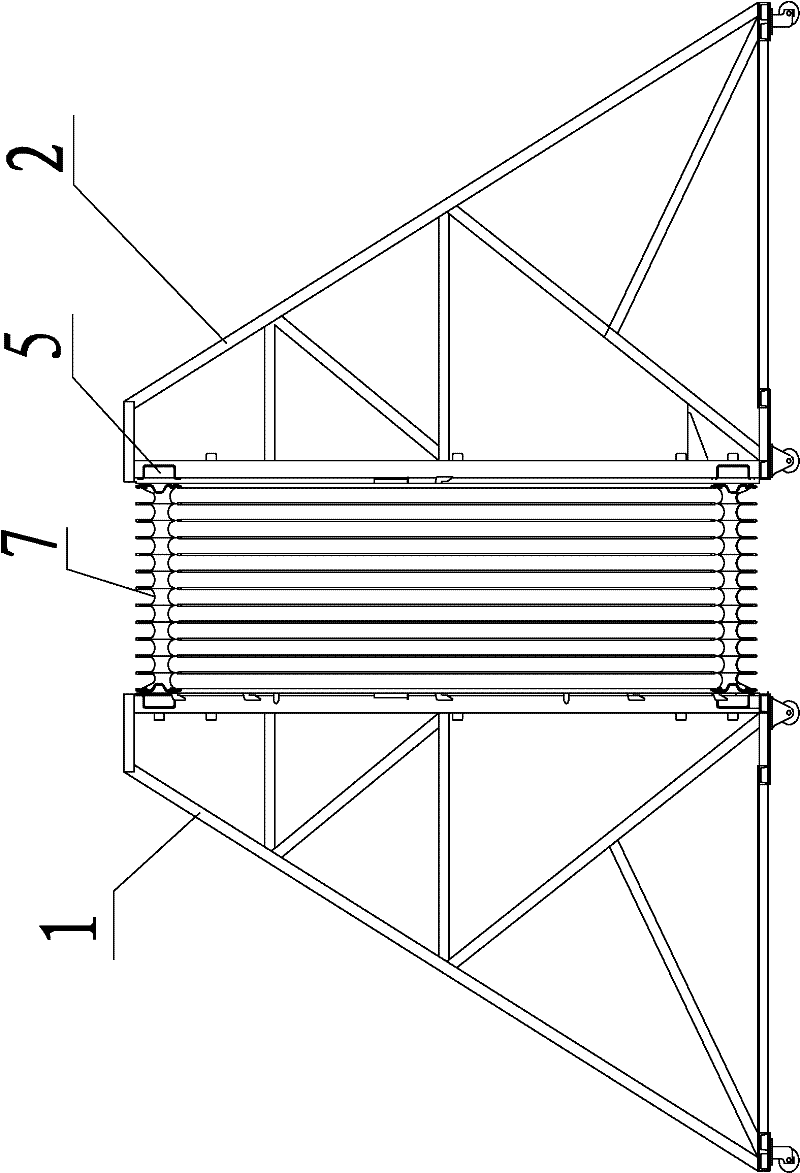

[0014] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

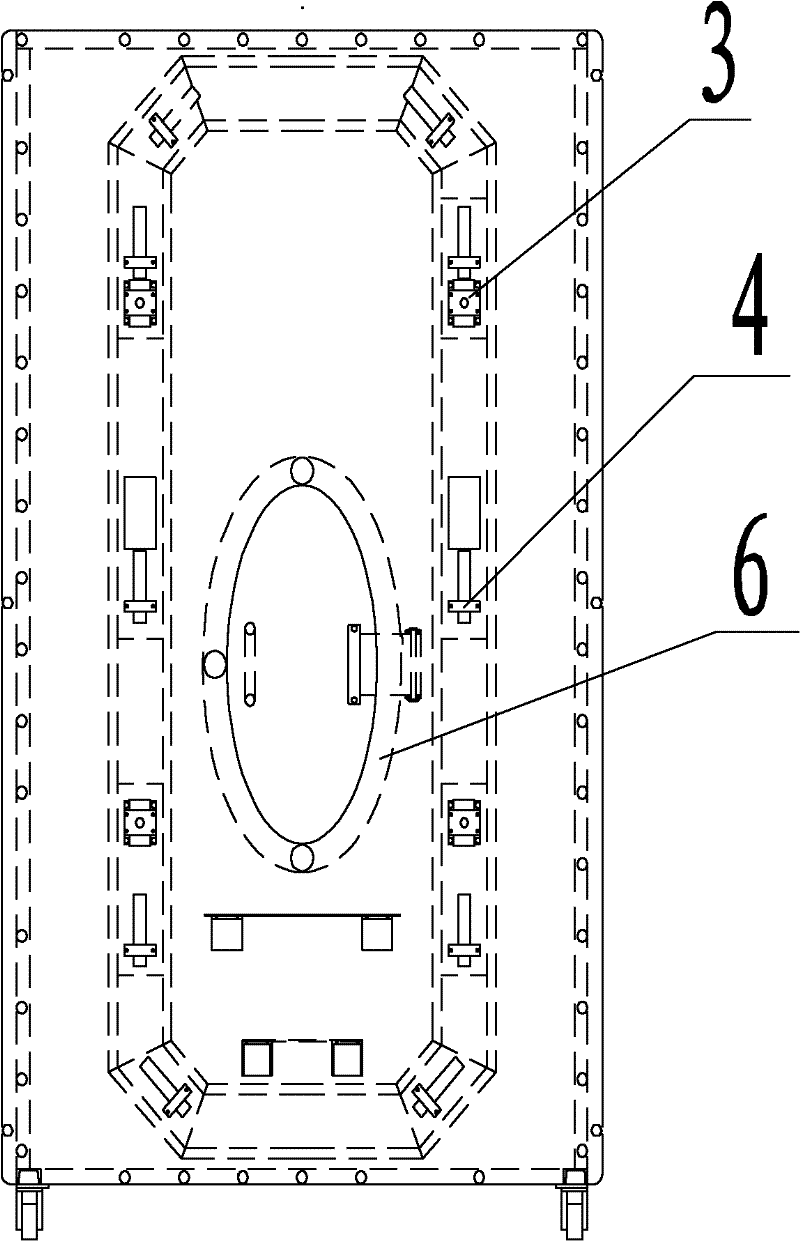

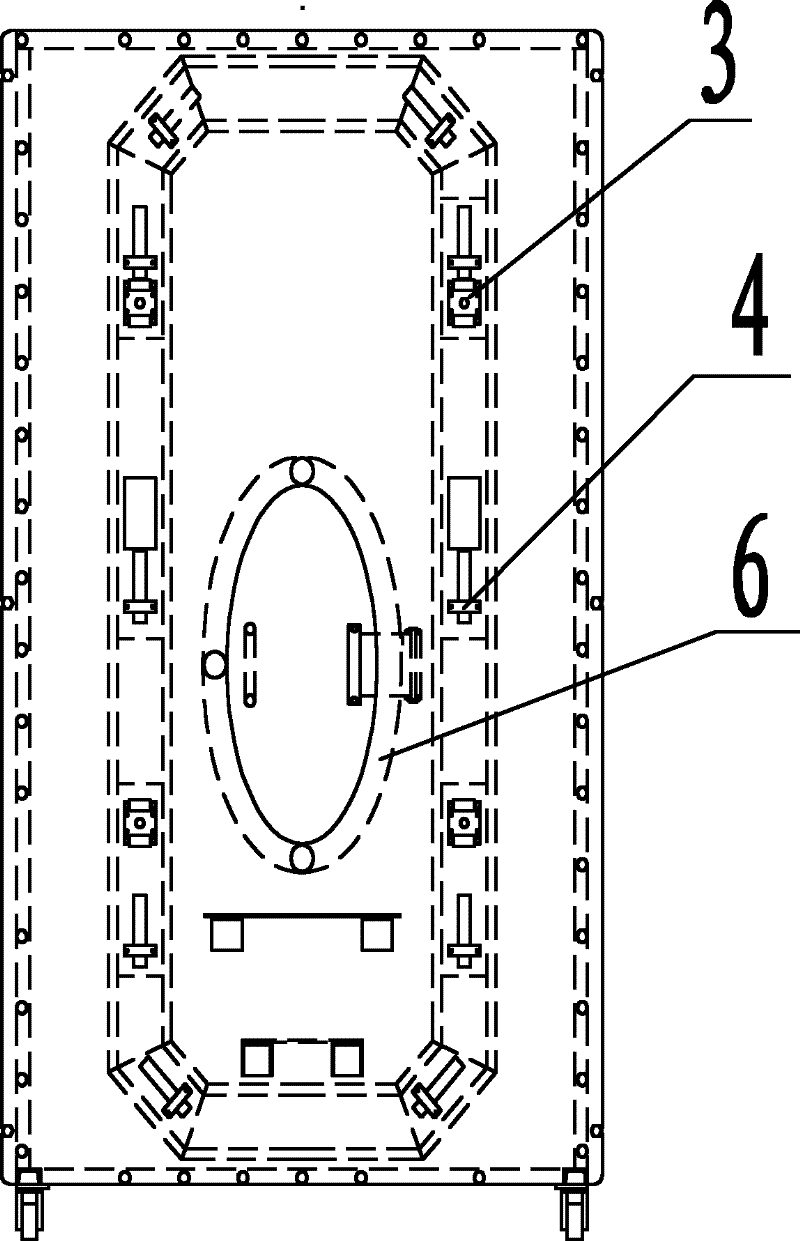

[0015] Such as figure 1 A kind of high-speed EMU train windshield test device shown has left stand 1, right stand 2, and the end wall of left stand 1, right stand 2 all has positioning seats 3 for positioning windshield 7, left stand 1, right stand 2 The end walls of the platform 2 are provided with lock plates 4 that are locked with the lock hooks of the windshield 7, and the end walls of the left platform 1 and the right platform 2 are provided with Us that can be squeezed with the rubber sealing strips of the windshield 7 to form a sealed space. Cavity 5.

[0016] There is an access door 6 on the end wall of the right frame platform 2, and the access door 6 is equipped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com