On-line test method for rock mixing rate of iron ore

A detection method, iron ore technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of increasing ore transportation cost, reducing the production efficiency of crushing process, increasing transportation cost, etc., and achieve huge economic and social benefits, The effect of reducing transportation costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

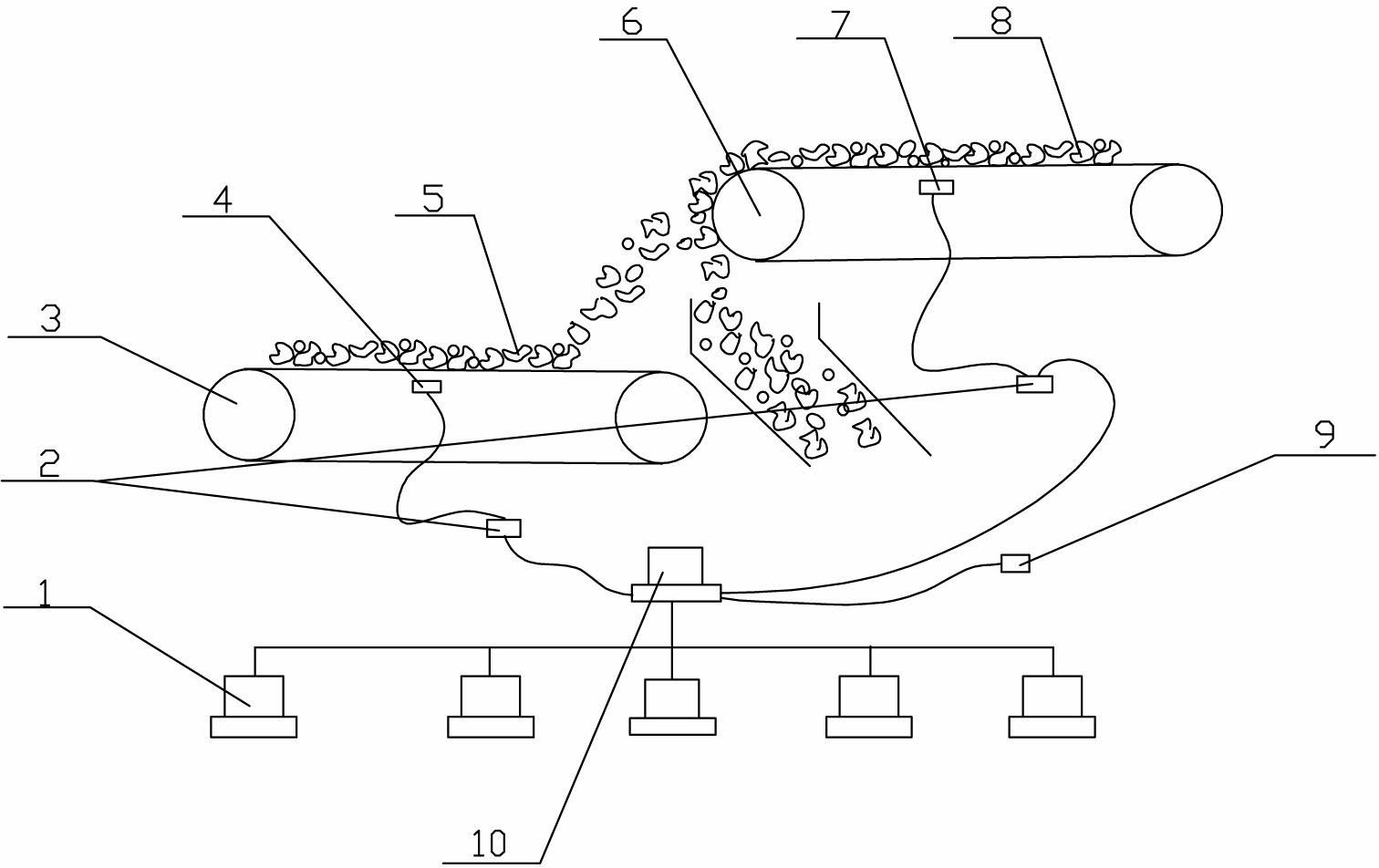

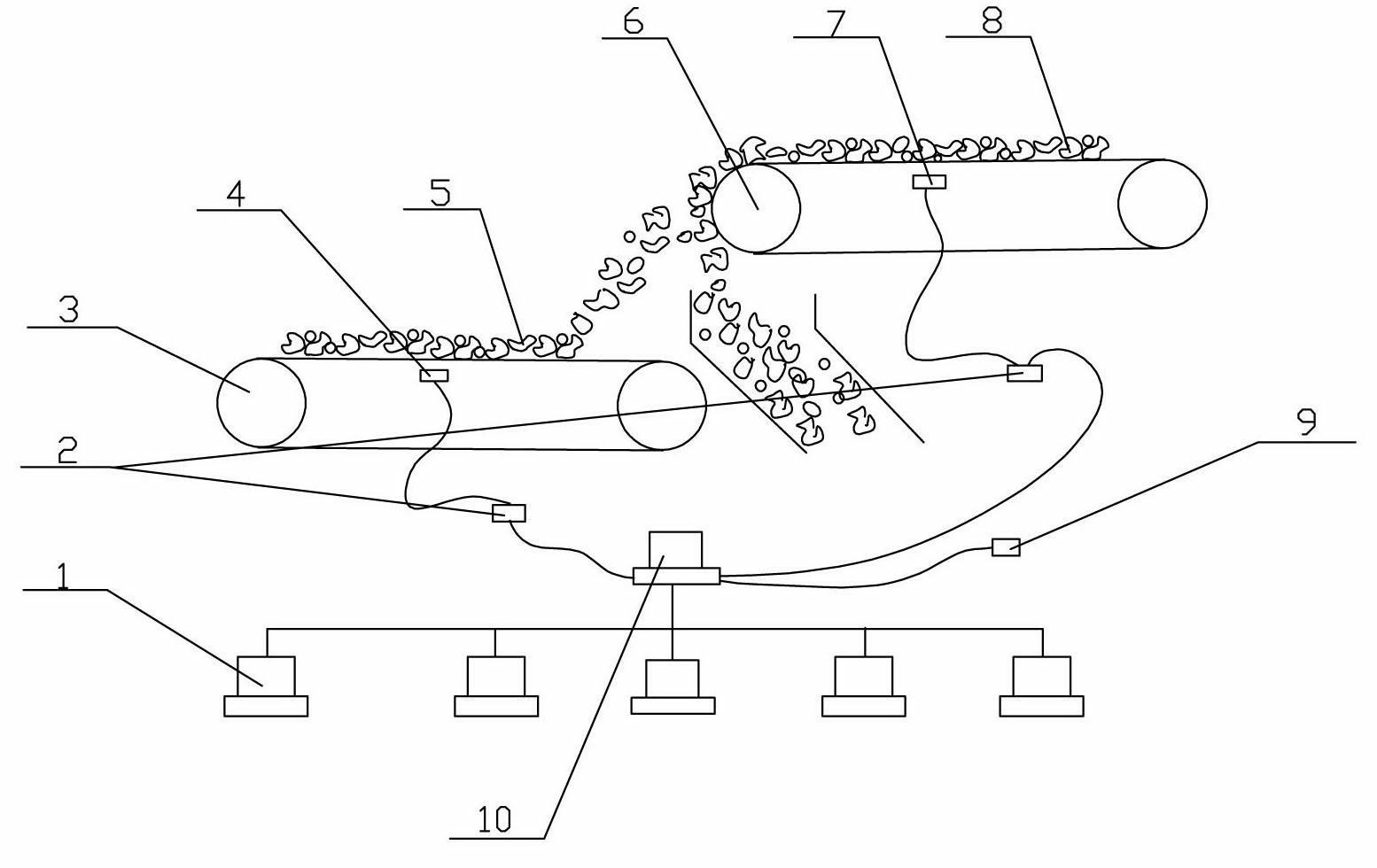

[0016] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0017] Such as figure 1 Shown, the iron ore mixing rate online detection method of the present invention is characterized in that comprising the following steps:

[0018] 1) The GPS positioning system of the ore transport vehicle is combined with the mine GIS system with independent characteristics, and the automatic identification device 7 of the transport vehicle installed at each ore outlet of the mining field and along the iron ore transport line automatically tracks the source of the ore,

[0019] 2) send the identification signals sent by these transport vehicle automatic identification devices 7 to the computer 6, so as to identify the ore source of the transport vehicle,

[0020] 3) Install a dry separation weight checker 3 under the ore feeding belt conveyor 1 of the dry magnetic separator to detect the ore throughput of the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com