Low-noise saturable reactor

A reactor and low-noise technology, applied in transformer/inductor cores, transformer/inductor coils/windings/connections, inductors with magnetic cores, etc., can solve the problem that high-order harmonic current cannot flow and the noise is large , iron core high-frequency vibration and other problems, to achieve the effect of low reactance value, low noise and good voltage waveform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

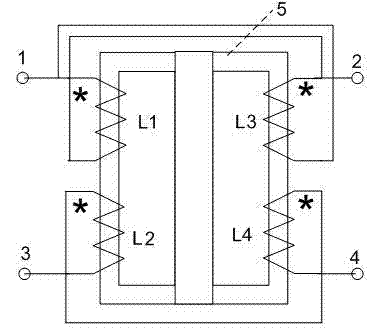

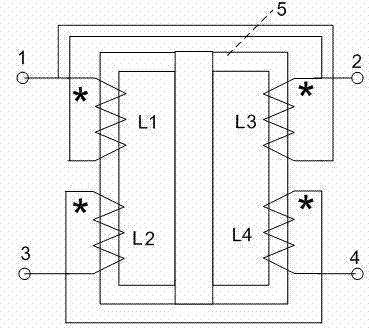

[0024] The structure and connection method of the saturated reactor are as follows: figure 1 shown. The AC terminal I1 and the AC terminal II2 of the device are connected in series to the AC transmission circuit; the DC terminal I3 and the DC terminal II4 of the device are connected in series to the DC power supply circuit.

[0025] Since the same-named end of the reactance coil L1 is connected to the opposite-named end of the reactance coil L3, it is one of the AC terminals I1 of the AC circuit of the saturable reactor, and the opposite-named end of the reactance coil L1 is connected to the same-named end of the reactance coil L3, which is a saturated reactor. Another AC terminal II2 of the AC circuit; and because the structure, number of turns, and winding method of the reactance coil L1 and the reactance coil L3 have the same technical requirements; therefore, the AC current flowing through the reactance coil L1 generates a magnetic flux Φ1 in the iron core The magnetic fl...

Embodiment 2

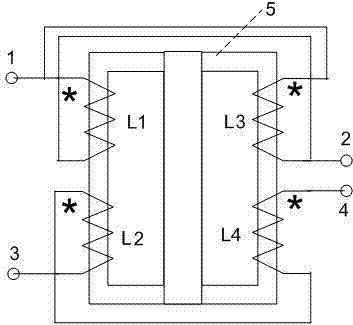

[0033] figure 2 Indicates another saturable reactor connection method with less noise; it includes a saturable reactor core; one side of the saturable reactor core is respectively equipped with a reactance coil L1 and a DC coil L2; the other side of the saturable reactor core is respectively corresponding to Install the reactance coil L3 and the DC coil L4; the reactance coil L1 has the same structure and the number of turns as the reactance coil L3; the DC coil L2 has the same structure and the number of turns as the DC coil L4;

[0034] The same-named end of the reactance coil L1 is connected to the same-named end of the reactance coil L3, and serves as one of the AC terminals I1 of the AC circuit of the saturated reactor; Another AC terminal II2 of the AC circuit of the device;

[0035] The same-named end of the DC coil L2 is connected to the different-named end of the DC coil L4. At the same time, the different-named end of the DC coil L2 is used as one of the DC termina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com