Electric connector and assembling method thereof

A technology of an electrical connector and an assembly method, which is applied to the parts, connection, and assembly/disassembly of a contact piece of a connection device, can solve problems such as unfavorable popularization and application, troublesome assembly process, and increased production cost of the connector. The effect of convenient and fast assembly, simplified production cost, and convenient follow-up wire bonding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

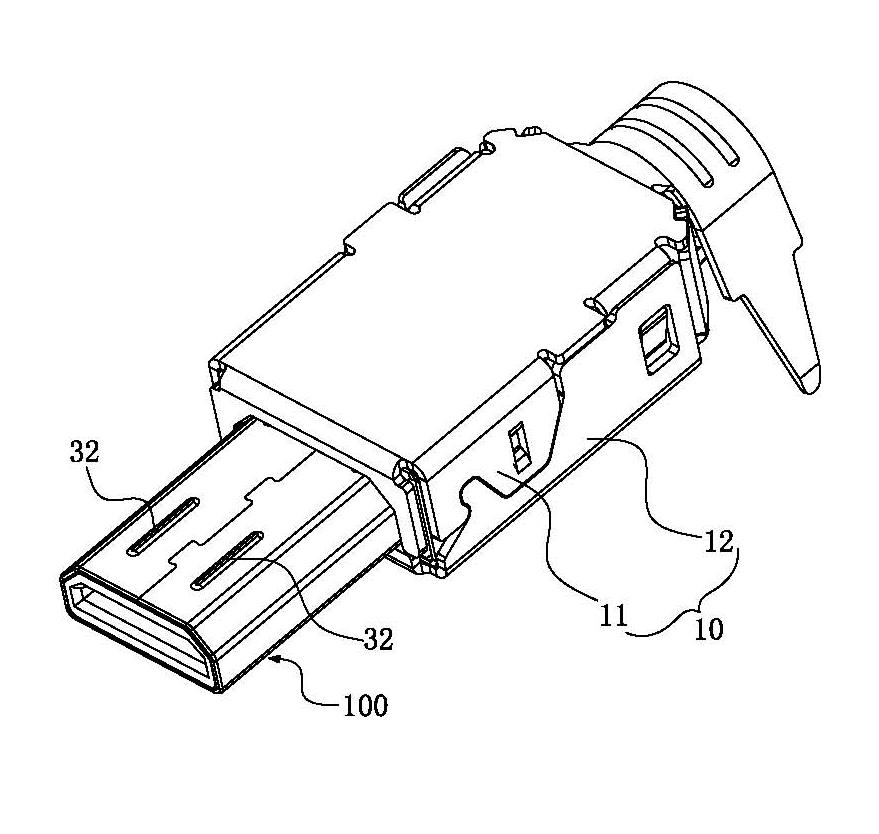

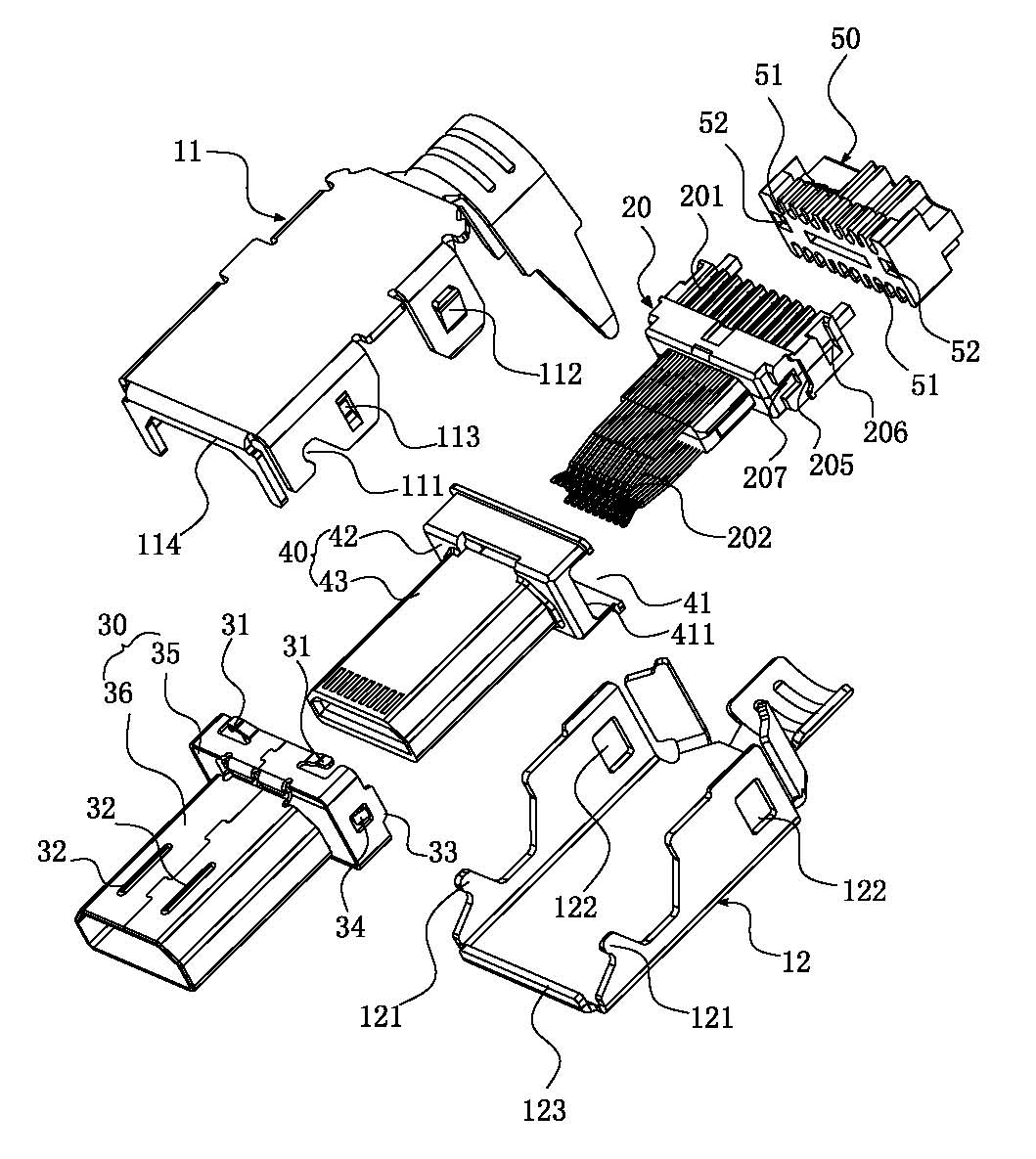

[0057] See Figure 1 to Figure 4 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a shielding shell 10, a terminal module 20, a metal connecting shell 30 and an insulating casing 40, and the insulating casing 40 is embedded in the metal connecting shell 30 A front-end insertion interface is formed inside, and one end of the terminal module 20 is embedded in the insulating casing 40; the aforementioned shielding casing 10 is covered on the outside of the terminal module 20 and the metal connection casing 30, and the metal connection casing 30 is connected to the shielding casing 10 and Its front end part is exposed outside the shielding shell 10 to form the socket part 100 .

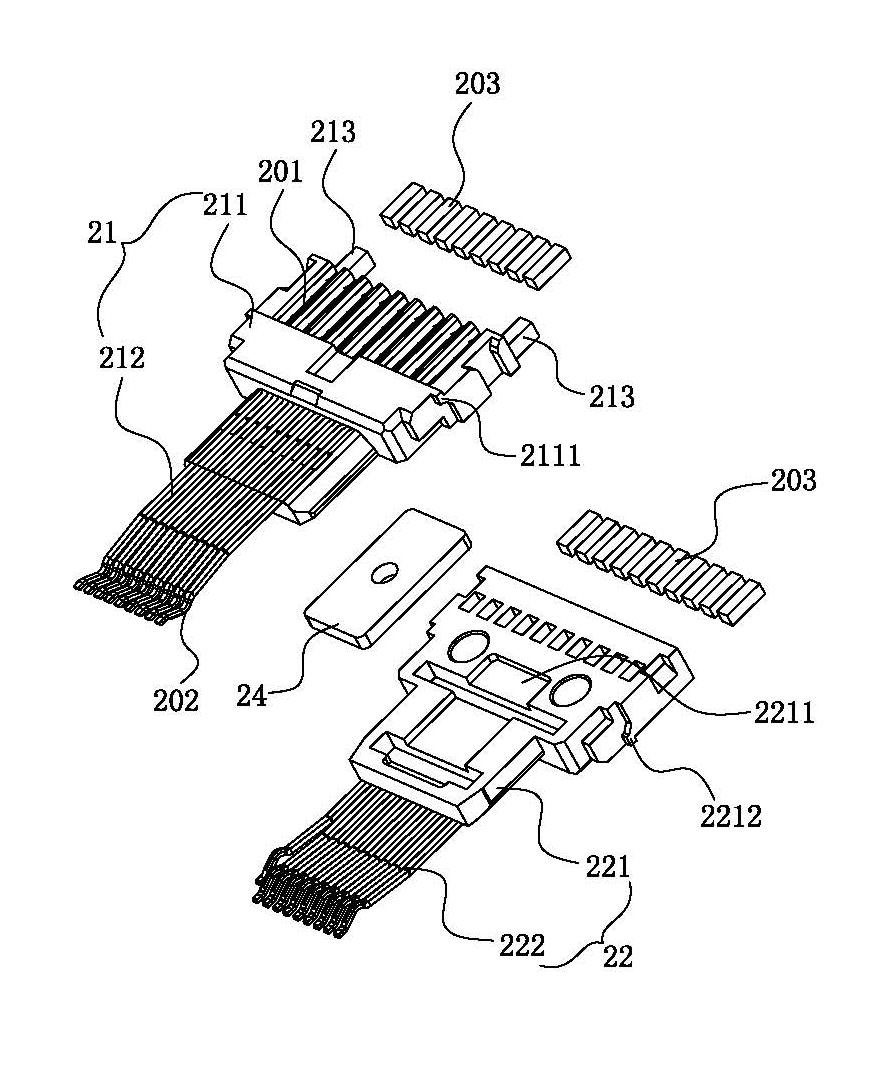

[0058] Wherein, the terminal module 20 includes a first terminal module 21 and a second terminal module 22 stacked up and down, the first terminal module 21 includes a first terminal port 211 and a The first terminal group 212 in 211, the second te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com