Self-starting permanent magnet motor with three-section-circular-arc magnetic pole structure

A technology of permanent magnet motor and magnetic pole structure, which is applied in the field of electric motors, can solve the problems of large influence on the performance of permanent magnet motors, high harmonic content of the no-load air gap magnetic field of permanent magnet motors, etc., and achieve the effects of improved impact and reduced harmonic content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

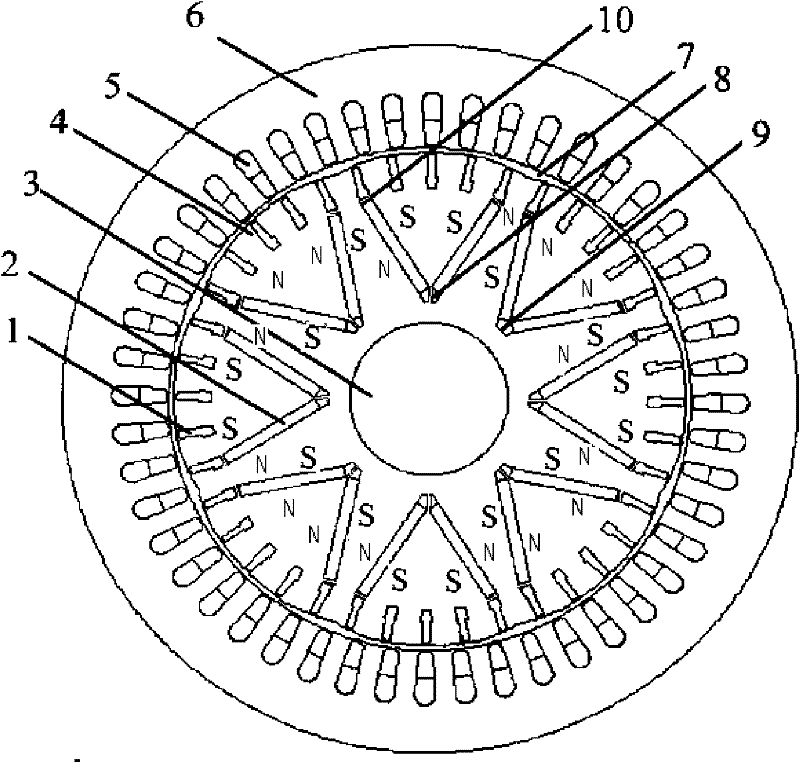

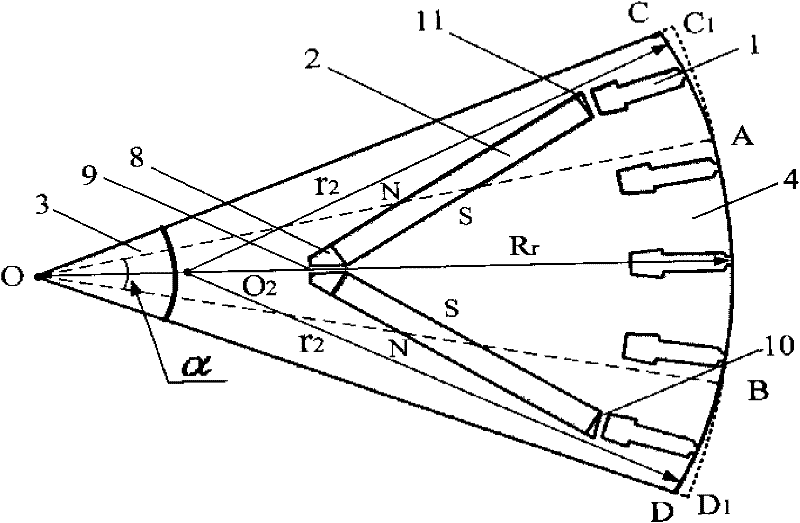

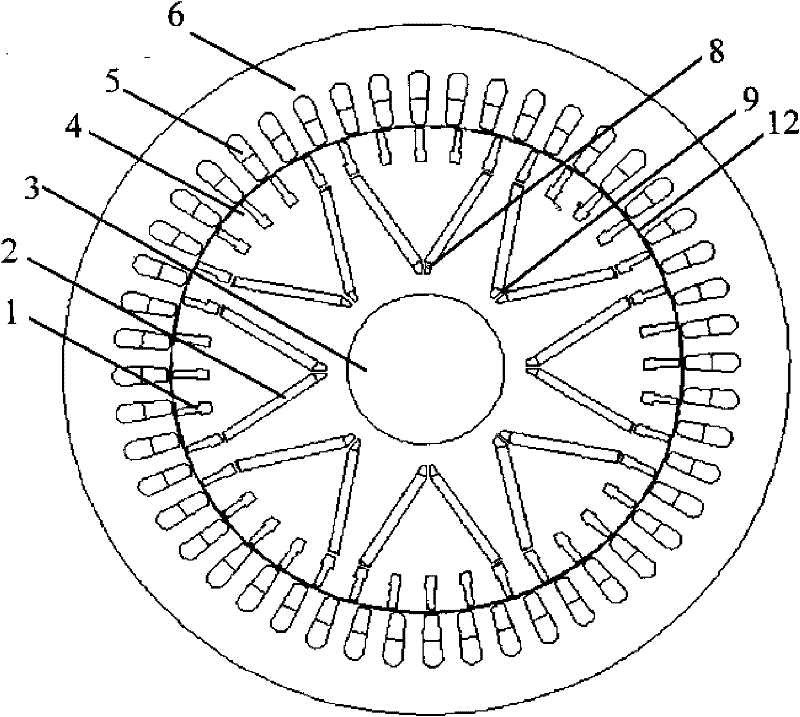

[0026] The present invention provides a self-starting permanent magnet motor with a three-segment arc magnetic pole structure. The stator is composed of a stator core 6 and a stator winding 5. The rotor core 4 is formed by laminating silicon steel sheets. The rotor silicon steel sheets are stamped with a starting guide bar. The squirrel cage slot and the permanent magnet slot are respectively placed with the squirrel cage rotor starting bar 1 and the permanent magnet magnet 2 made of cast aluminum. The N and S magnetic poles of the permanent magnet are arranged alternately, and the two ends of the permanent magnet of each pole are respectively provided with a bottom air isolation groove 8, a top air isolation groove 11, a permanent magnet bottom magnetic isolation bridge 9 and a permanent magnet top Magnetic isolation bridge 10 (such as figure 2 (Shown) in order to ensure the rigidity of the entire rotor without causing excessive magnetic leakage of the permanent magnets in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com