Eddy current paddle of reaction kettle

A vortex type, kettle blade technology, applied in the field of vortex type reactor blades, can solve the problems of reducing the use efficiency of the reactor, energy waste, etc., and achieve the effect of ingenious structure design, high mixing efficiency, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

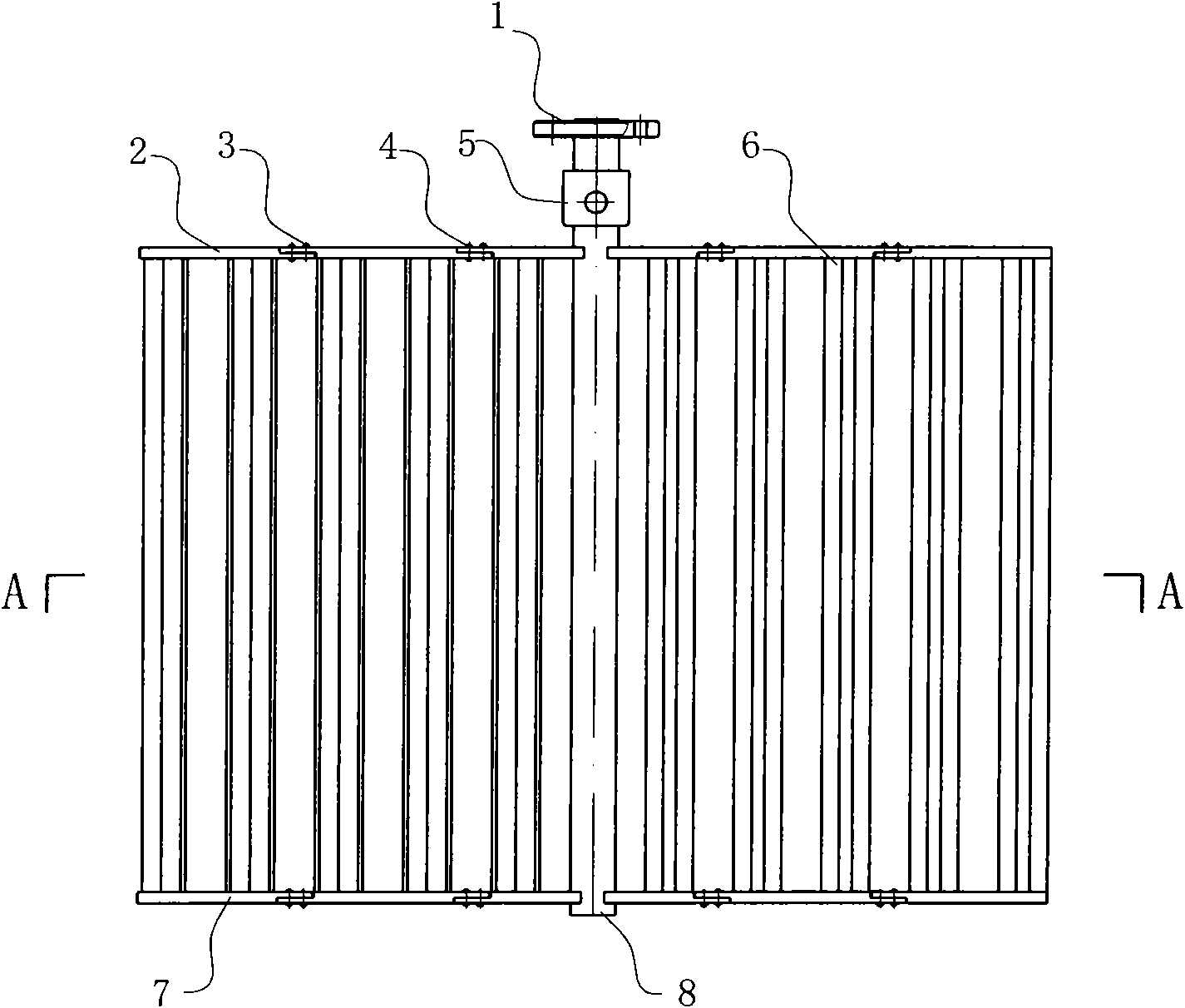

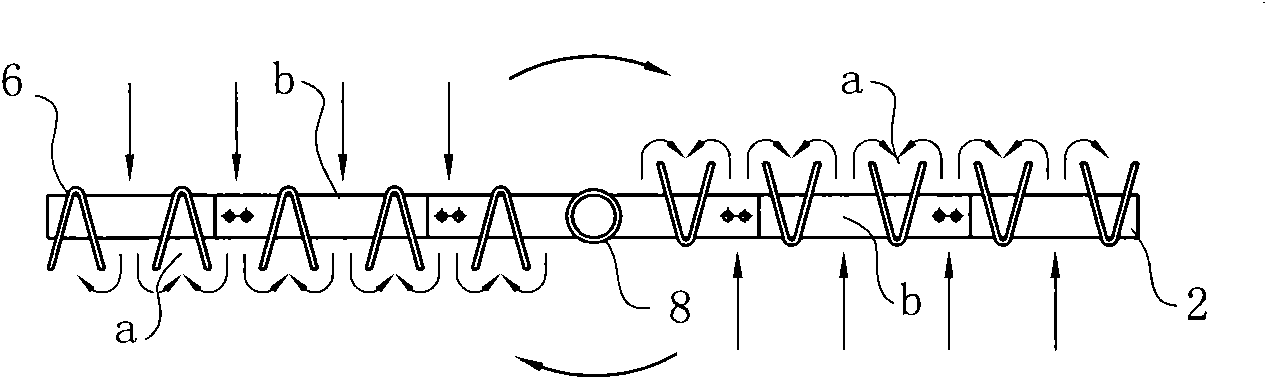

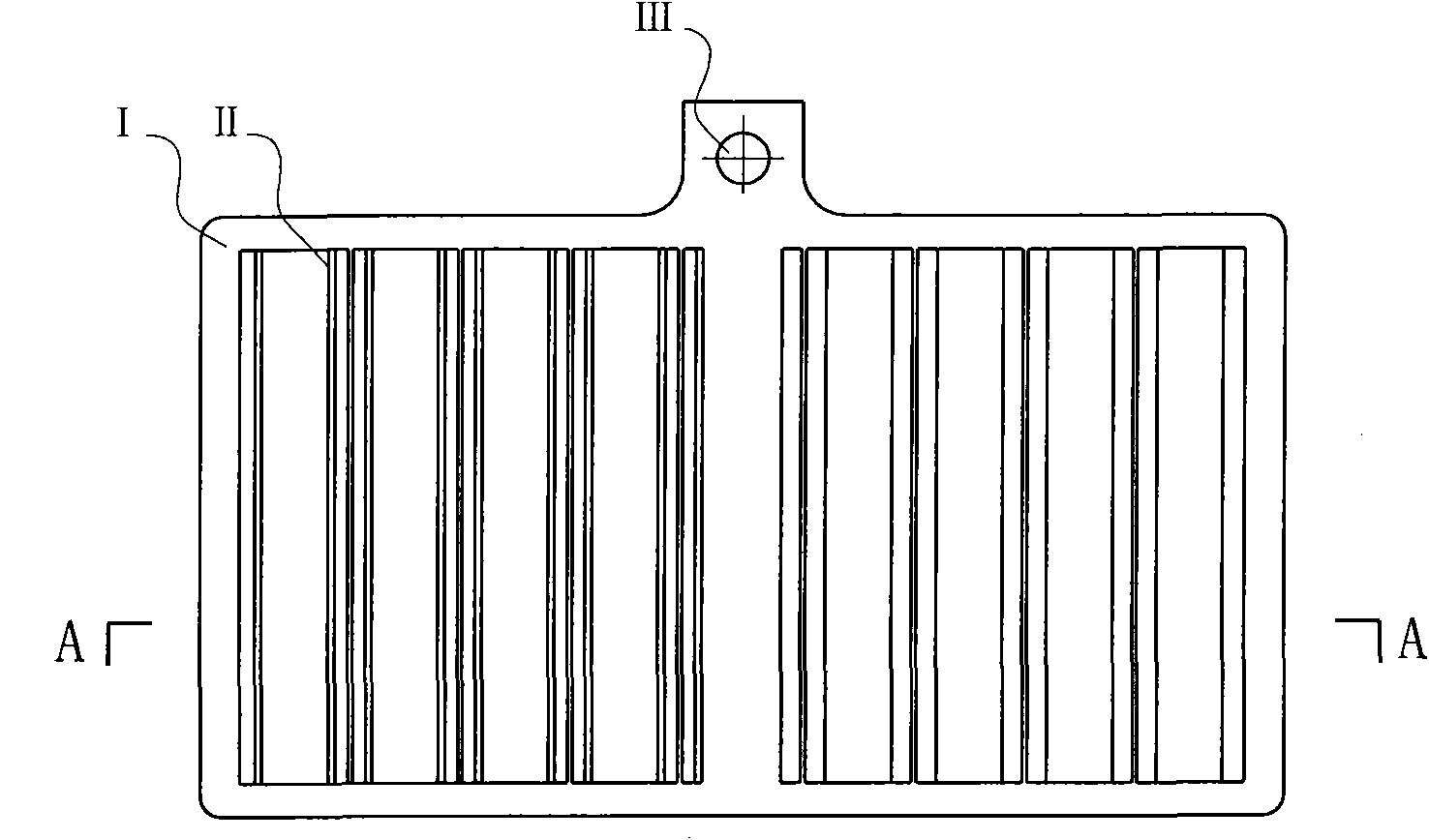

[0010] See attached figure 1 , a vortex reactor paddle disclosed by the present invention is characterized in that it is an industrial product: two metal upper folding plates 2 and lower folding plates 7 are formed on the central axis 8, and between each folded plate A number of V-shaped plates 6 are made, wherein the connection between the folded plates utilizes riveted movable shafts 4, and the bolts 3 are used to fix the folded plates firmly, and according to the requirements of the direction of rotation, the upper folded plate 2 and the lower folded plate The V-shaped plate 6 fixed or welded between the plates 7 takes the central axis 8 as the dividing line, and the direction of the included angle a of the V-shaped plate on the right side is opposite to that on the left side. There is a joint 5, and a flange 1 is connected to the joint 5; the product used in the vortex reactor for the laboratory is characterized in that: a coupling hole III is formed on the middle upper pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com