Automatic spot welding system

An automatic spot welding and control system technology, applied in welding equipment, resistance welding equipment, program control manipulators, etc., can solve the problems of low product yield, small size, difficult operation, etc., and achieve high assembly efficiency and high product yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

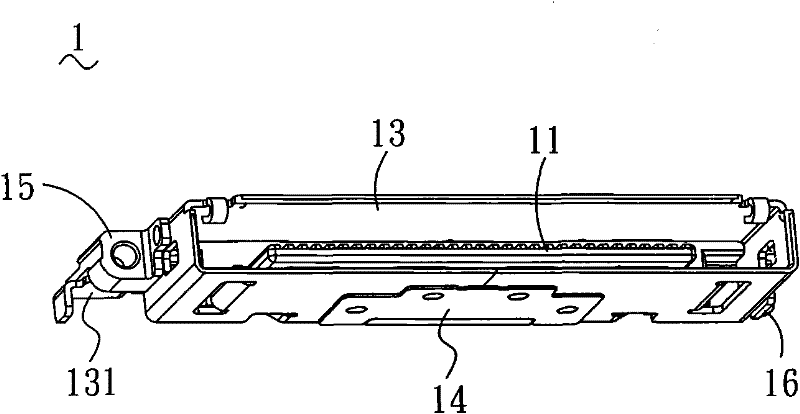

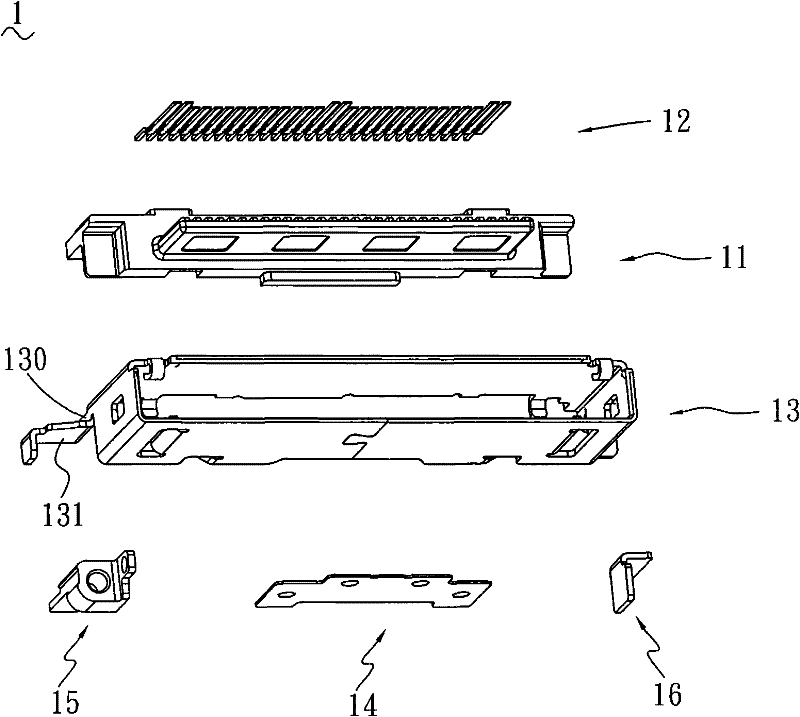

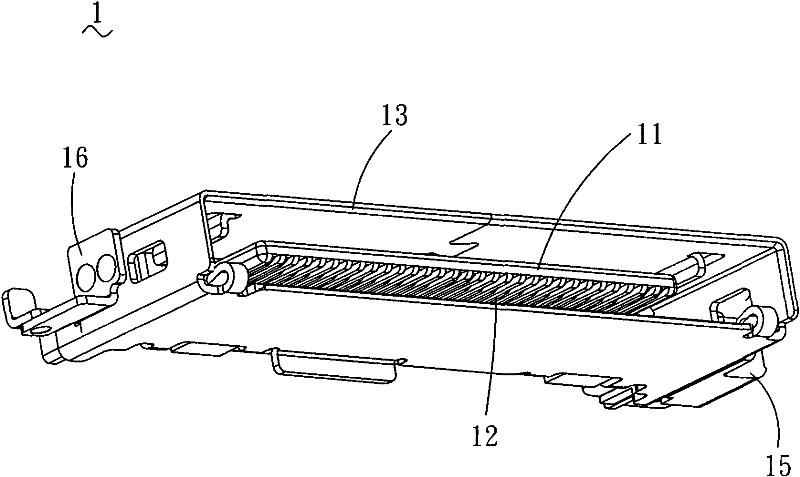

[0030] The automatic spot welding system of the present invention is used to weld several weldments on the metal shell of the workpiece from different directions during the assembly process of the workpiece. In this embodiment, the workpiece is a connector 1, such as Figure 1 to Figure 4 As shown, the connector 1 includes an insulating body 11 , a plurality of terminals 12 mounted on the insulating body 11 , and a metal shell 13 covering the insulating body 11 . The upper rear ends of the side plates of the metal shell 13 continue to extend backwards to form an extension portion 130 , and the lower edges of the two extension portions 130 are respectively bent and extended vertically outward to form a welding plate 131 . A first weldment 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com