Crane

A technology of cranes and winches, applied in the field of lifting equipment, can solve problems such as matching installation equipment, large lifting booms, and inability to realize automatic retraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments (accompanying drawings):

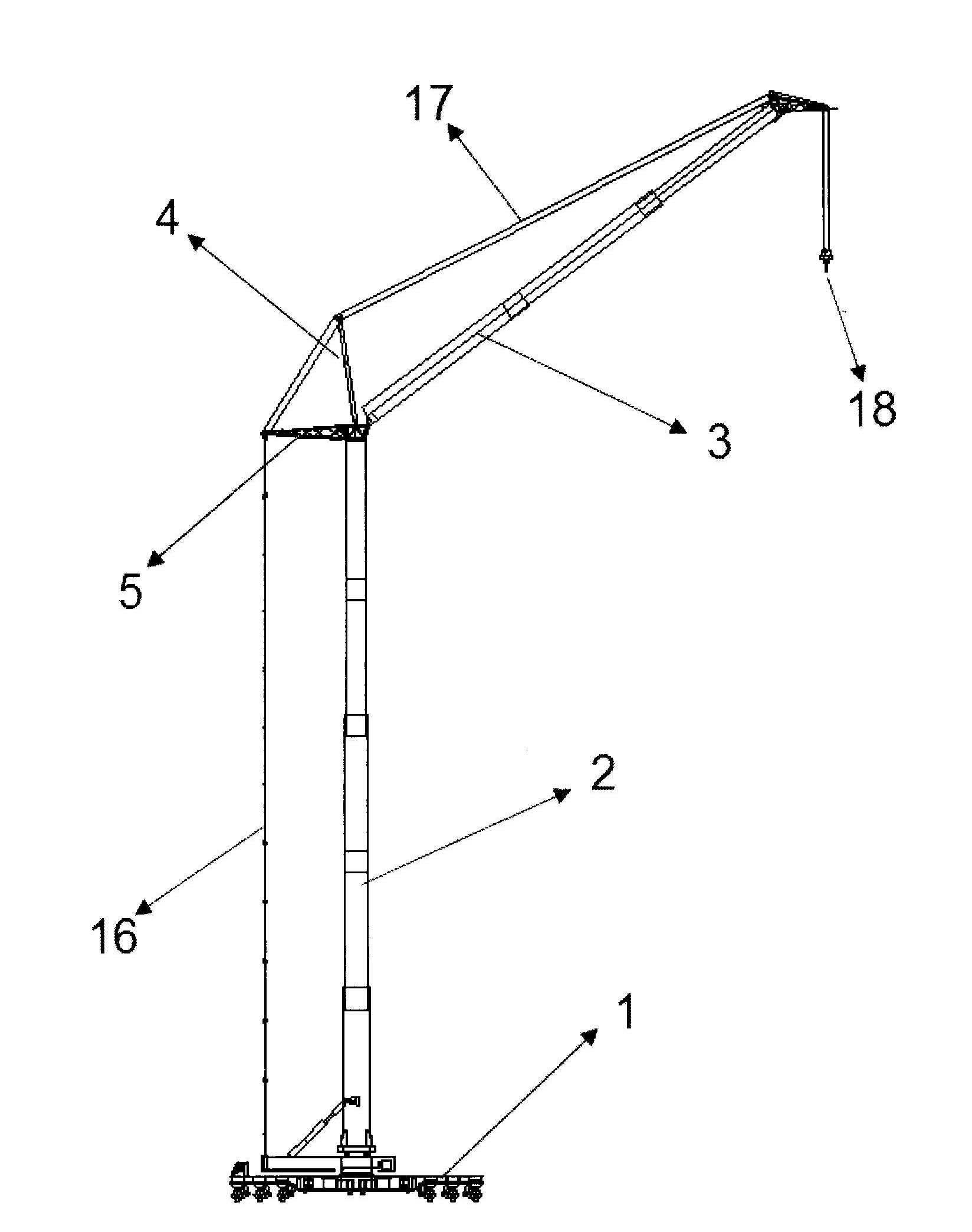

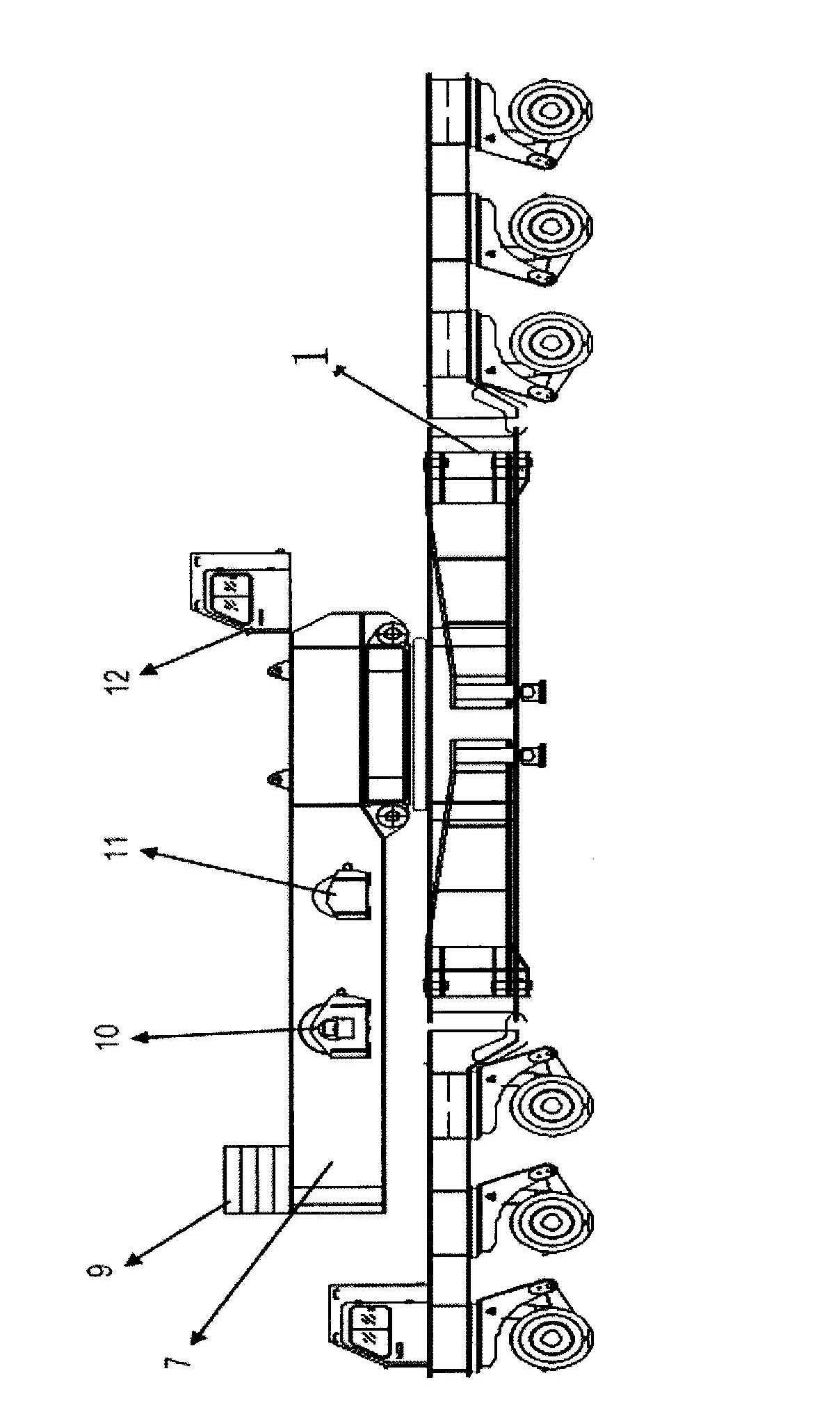

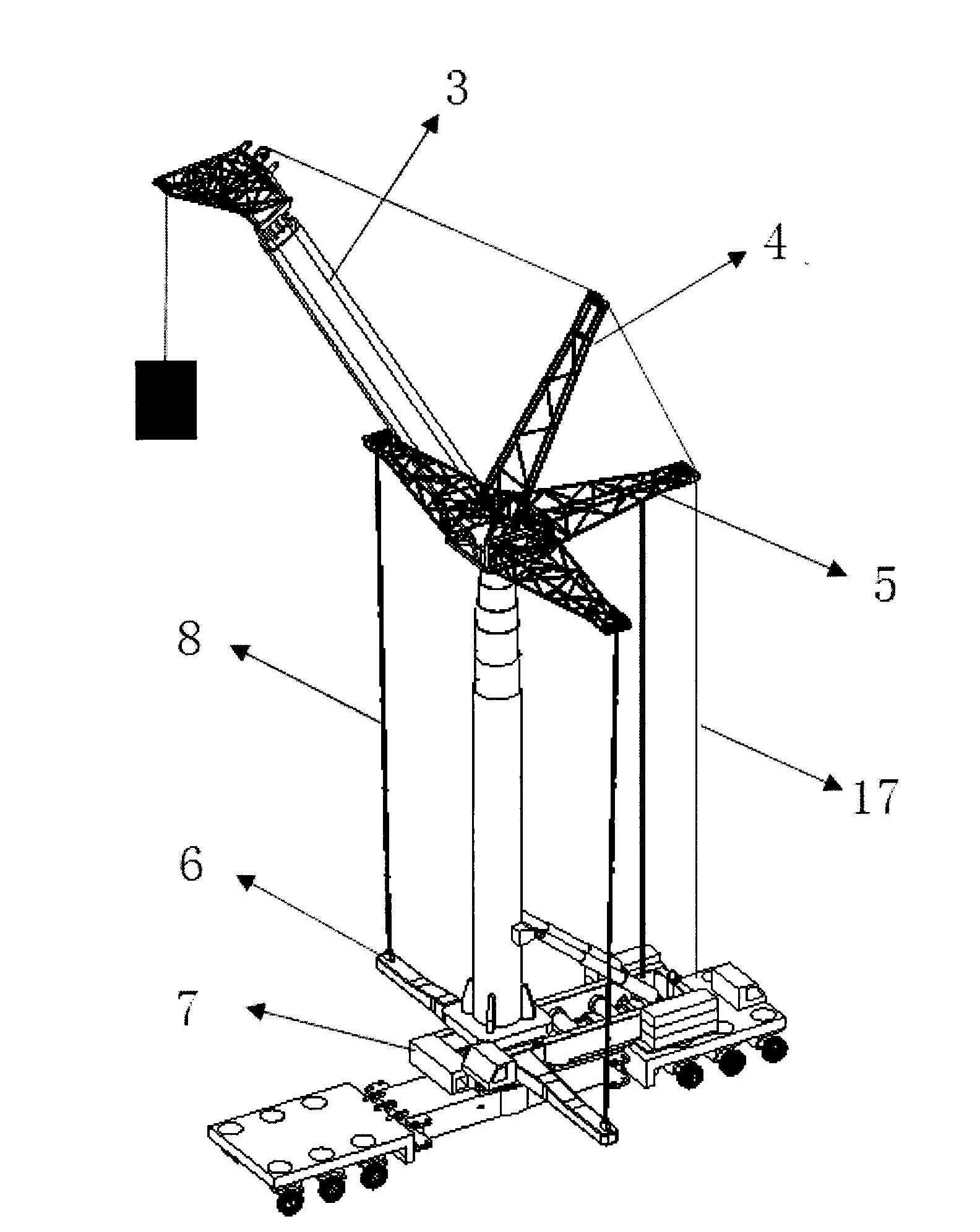

[0026] like figure 1 , 2 As shown in 3 and 3, the crane of the present invention mainly includes a walking chassis 1, a slewing platform 7 which is located on the walking chassis 1 and can rotate 360°, is located on the upper tower body 2 of the slewing platform, and is arranged on the upper end of the tower body. The support 5, the luffing support arm 4, and the electrical control unit and other parts; the electrical control unit is a set of electrical, hydraulic and gas integrated systems.

[0027] At least one of the tower body 2 and the boom 3 is composed of at least two box-type telescopic joints that are nested together, and when the extension length reaches the limit, an overlapping portion 15 is maintained between every two adjacent telescopic joints (see Figure 5 ); the lower end of the tower body 2 is hinged on the rotary platform 7, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com