Full-hydraulic integrated multipurpose cutting driller

A full-hydraulic, multi-purpose technology, which is applied in the fields of earthwork drilling, drilling equipment, drilling equipment and methods, etc., can solve the problems that cutting drilling rigs cannot form holes, etc., so that it is not easy to open welding fractures, improve working conditions, and reduce stress. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing:

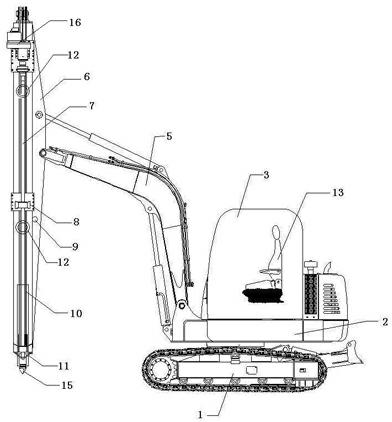

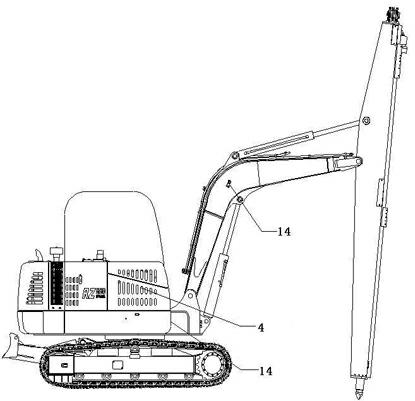

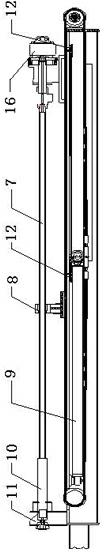

[0035] combine Figure 1 to Figure 4 , the present invention has the following parts as shown: walking structure 1, rotating body 2, driver's cab 3, air compressor 4, support bracket 5, drill arm 6, and the aforementioned drill arm 6 includes drill rod 7, propulsion oil cylinder 9, power head 16. The rotating body 2 is installed on the top of the walking structure 1 and can rotate freely; the cab 3 and the air compressor 4 are located on the top of the rotating body 2; one end of the support bracket 5 is connected to the rotating body 2, and the other end is connected to the drilling arm 6 The drill arm 6 adopts a box-shaped beam structure, and the front end is equipped with a dust guide cover 11, and the propulsion cylinder 9 is a built-in type, and the drill arm 6 has a middle support structure 8; by replacing the part at the front end of the drill arm 6, other Mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com