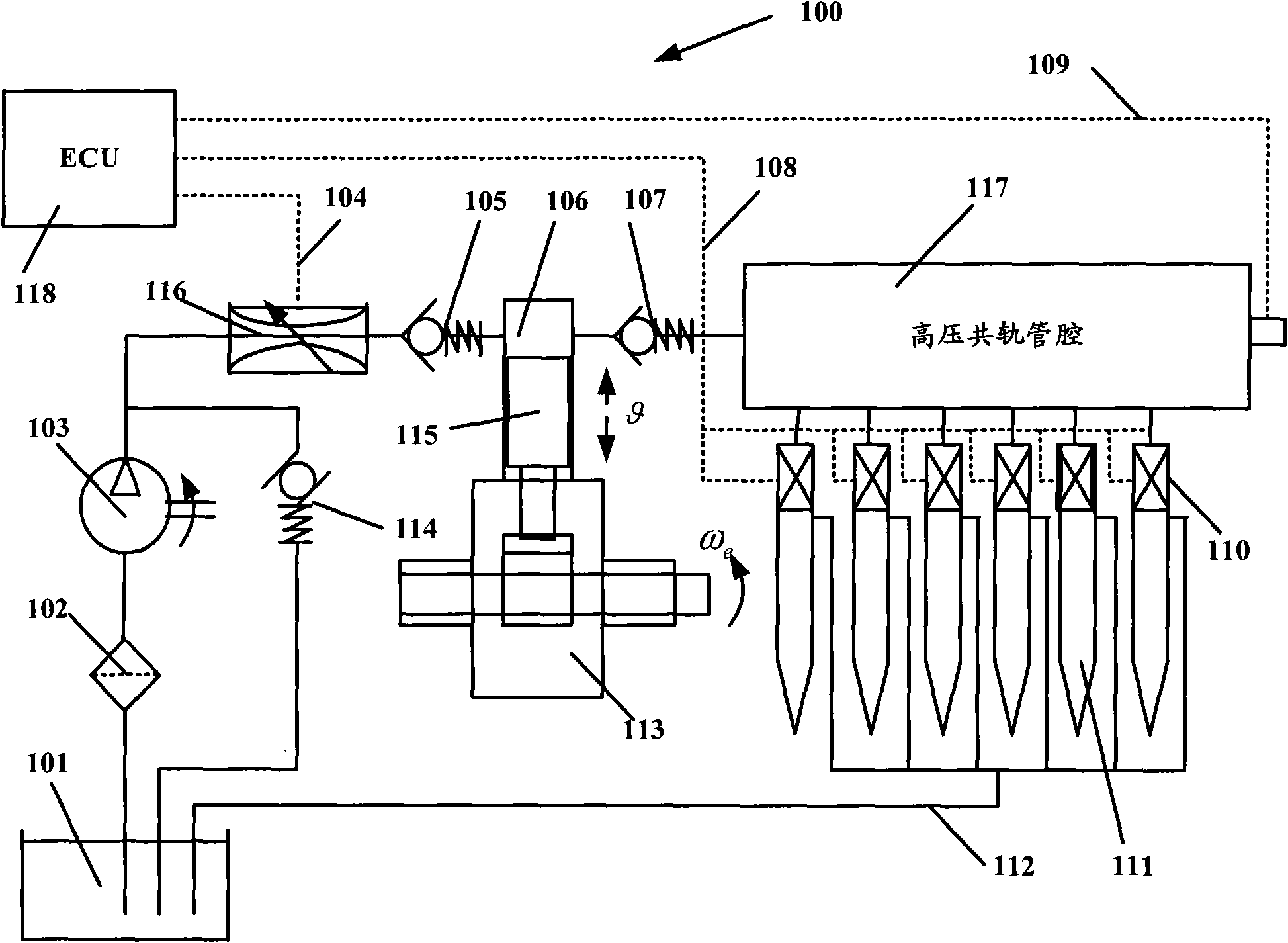

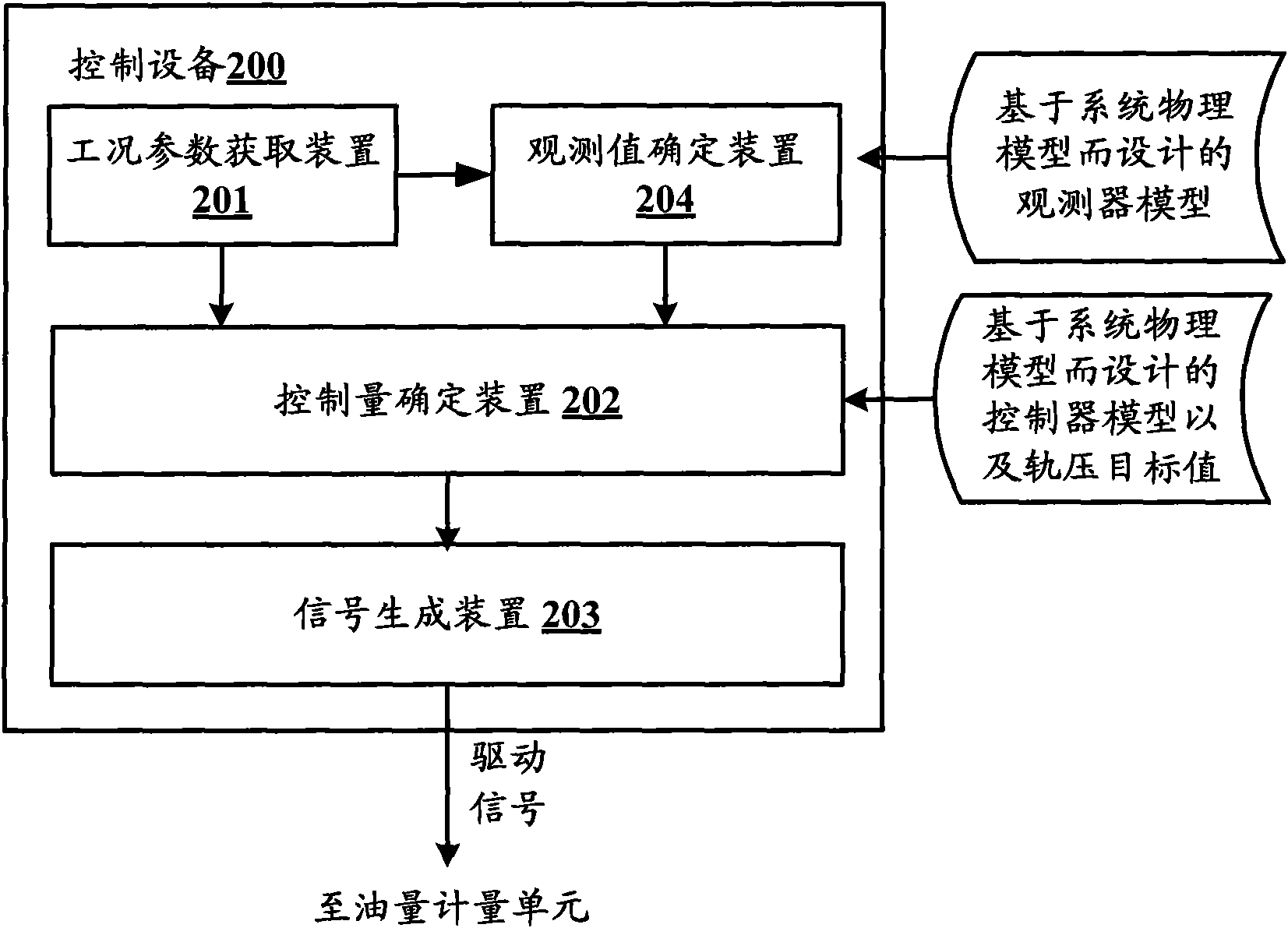

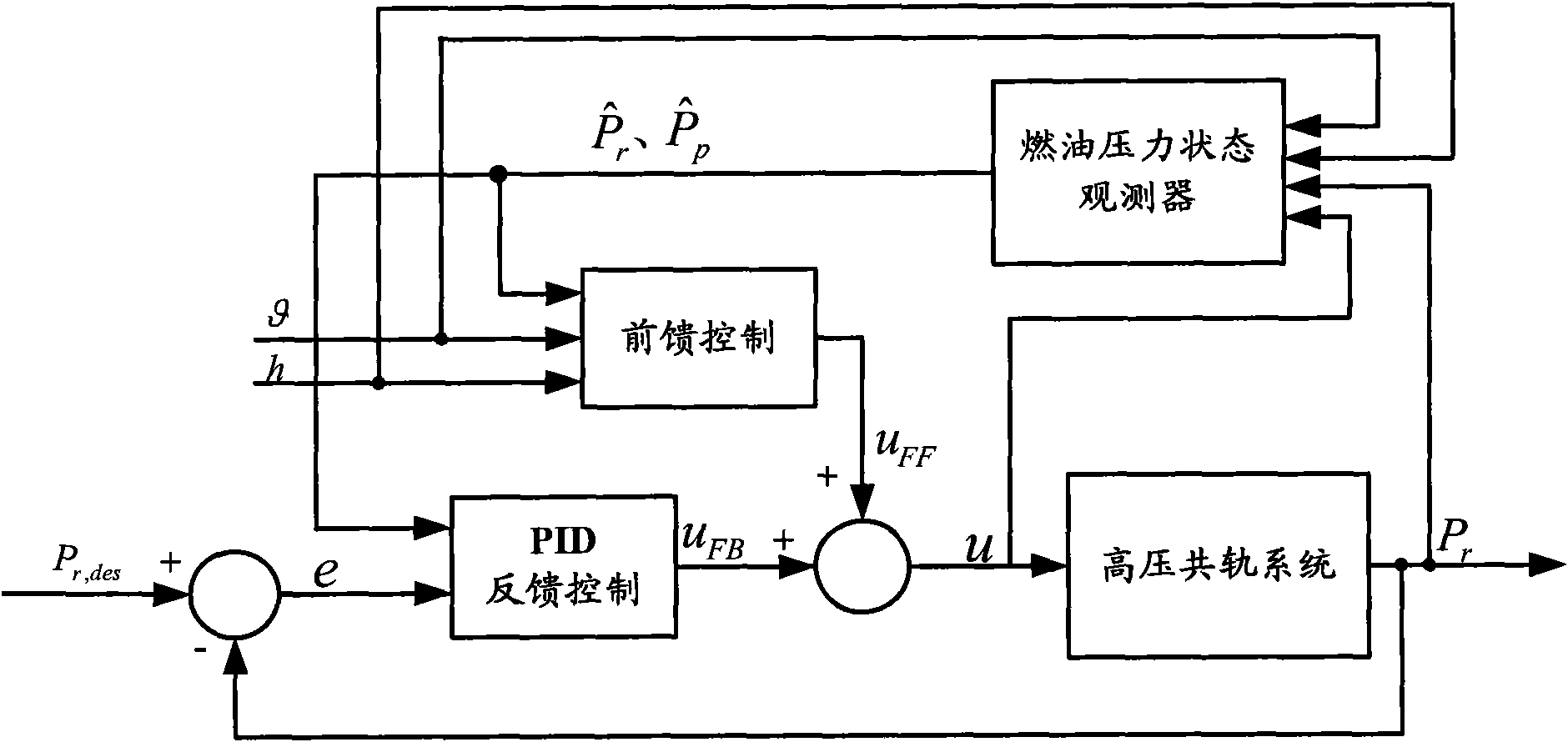

Equipment and method for controlling high-pressure common rail system of diesel engine

A high-pressure common rail system and diesel engine technology, applied in mechanical equipment, engine control, machine/engine, etc., can solve problems affecting the consistency and error of fuel injection of engine power cylinders, and reduce calibration workload and deviation , improving efficiency and functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, the device and method for controlling a high-pressure common rail system provided by the present invention will be described in detail through embodiments with reference to the accompanying drawings. It should be understood that these embodiments are given only to enable those skilled in the art to better understand and implement the present invention, rather than to limit the scope of the present invention in any way.

[0024] In addition, the term "operating condition parameter" used herein refers to any value of a physical quantity that can indicate the (target or actual) physical state or operating condition of the engine. Also, herein, "parameter" and the physical quantity it represents may be used interchangeably. For example, "the parameter indicating the rotational speed of the camshaft" and "the rotational speed of the camshaft" have equivalent meanings herein. Moreover, in this paper, assuming that P represents a specific physical quantity, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com