Method and device for operating an internal combustion engine, in particular an internal combustion engine of a motor vehicle

A technology for internal combustion engines and exhaust devices, which is applied to the operation of internal combustion engines of motor vehicles and the field of devices for internal combustion engines. It can solve problems such as the infeasibility of exhaust gas recirculation, achieve the effects of improving the degree of inflation and reducing component costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

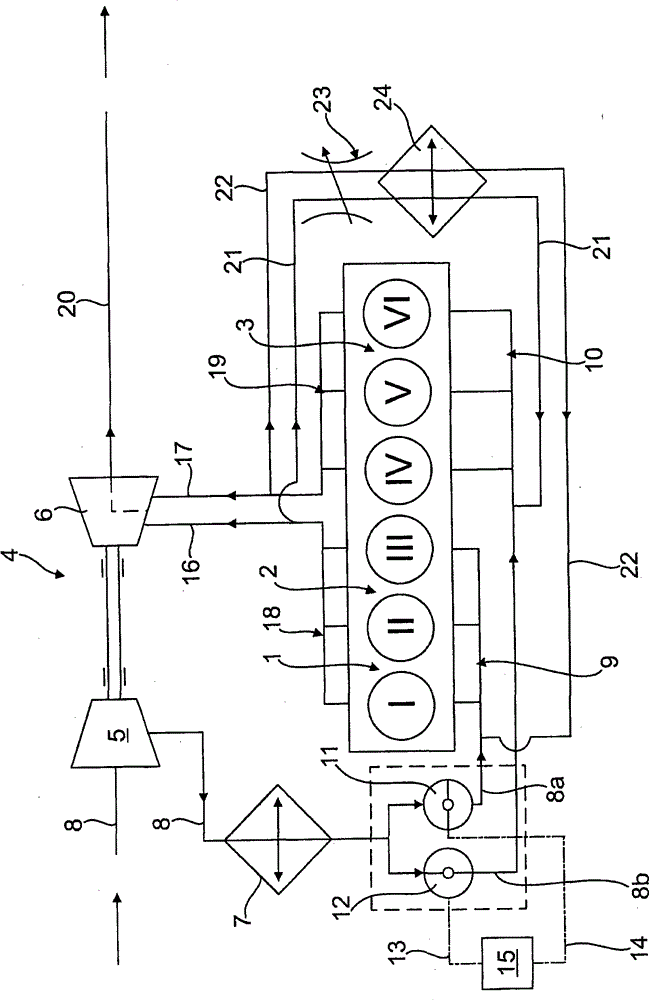

[0019] In addition, in figure 1 The exemplary arrangement shown in includes an exhaust gas turbocharger 4 with a compressor 5 and a turbine 6 . Upstream of the internal combustion engine, a charge air cooler 7 is connected downstream of the compressor 5 , wherein a charge air line 8 leading from the compressor 5 through the charge air cooler 7 in the direction of the internal combustion engine 1 Downstream of the air cooler 7 branch off into a first charge air line 8 a and a second charge air line 8 b , which are thus conducted in two streams to the internal combustion engine 1 . In this case, the first charge air line 8 a communicates with the first cylinder bank 2 via the intake manifold area 9 according to fluid technology and the second charge air line 8 b is fluidically connected to the second cylinder bank 3 via the second intake manifold region 10 . In this case, each cylinder of the internal combustion engine is conventionally associated with an intake duct which fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com